Pleated Filters: The Great Problem Solver

Compact design with high surface area addresses filtration bottlenecks

January 5, 2022

Dale Kadavy, senior product engineer, and Matthew Campbell, technical sales manager, Parker Hannifin

Undersized dust collectors, differential pressure limiting production and overextended employees tied up with lengthy maintenance: The dust collection baghouse has no shortage of problems. Before scrapping a dust collection system and rebuilding expensive infrastructure, it is worth considering a simple filter swap to a pleated-style filter to address some of these headaches.

While pleated filters have a higher initial cost than bags and cages, operating cost savings can be significant over time in many applications. By packing three to four times more filter surface into a shorter package, pleated filters can often cost-effectively reduce dust emissions, pressure drop, and filter durability issues.

Certain pleated filter elements and cartridges have already solved these issues, saving downtime in food, pharmaceutical, wood, aluminum, power, cement, and other process industries, with gas temperatures ranging from -20 to 400°F. Application engineers can help assess individual applications and provide insight into whether the type of dust and performance parameters merit considering pleated filter options.

Compact Size Plus Increased Filtration Surface Area Lower Pressure Drop

Because the folded media of a pleated filter contains greater surface area than a bag of the same diameter and length, it reduces filtration velocity and, therefore, often lowers pressure drop across the filtration media. While this can result in lower energy bills, the real savings often come from increased production.

Strategic placement of pleated filters reduces can velocity. When can velocity is too high, it prevents dust from dropping off the filter during cleaning. Released dust remains suspended and re-adheres to the filter surface. Pleated elements can solve this problem by reducing the total number of filters without sacrificing total filtration area. This creates more open space between filters and therefore lowers can velocity.

Depending on filter diameter, a traditional filter bag could be replaced by a pleated filter of one-third the length and with the same filter area.

Better Durability Cuts Downtime

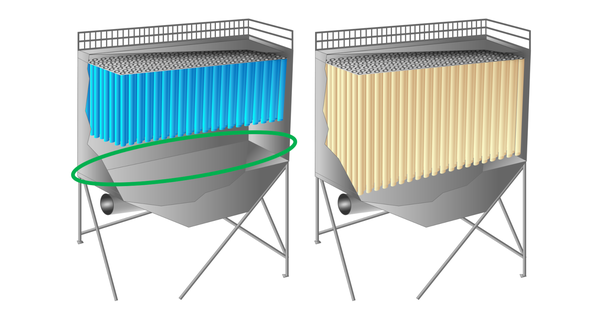

The filter length difference between bags and pleated-style filters also factors into filter wear and change-out frequency. If filter bags are wearing at the bottom, swapping them out for shorter pleated elements gets the filters out of the abrasion zone (see Figure 1). An additional benefit: Unlike filter bags, pleated filters have a protective urethane or metal end cap at their base that provides additional abrasion protection. This feature increases filter life.

Figure 1: Pleats offer greater surface area while getting the filters out of the abrasion zone.

When pleated filters eventually need to be changed, the process is quicker and requires less labor than bag and cage types, reducing downtime and labor costs. A pleated filter element is a one-piece unit and does not require the often cumbersome removal of a stuck cage from a long filter bag. Given that the environment is often hot and dusty during bag removal, maintenance personnel generally prefer changing pleated elements instead of filter bags and cages.

Pleated filters have a protective urethane or metal end cap at their base that provides additional abrasion protection.

Rugged and Forgiving Design Maintains Filtration Efficiency

The more often a filter is cleaned, the quicker it will wear. As filter bags wear, particulate emissions increase. Today’s stringent emissions standards often determine filter life.

Typically, most emissions are released during pulse cleaning. A pleated filter with more surface area and a permeable dust cake will pulse less frequently than a filter bag. This lengthens its emissions-based lifecycle. When pulsing, an iPlas strap (see Figure 2) holds the pleats firmly in place and maintains pleat spacing.

iPLAS utilizes a thermoplastic polymer creating a rigid integrated band providing excellent strength and durability while retaining flexibility

Another point for pleats: A more forgiving installation approach. A number ofpleated filters include a flexible rubber or molded urethane top that creates an effective seal at the tube sheet and accommodates some variation in the tube sheet holes. Metal-topped options use a simple felted cuff in the installation process. Bags in contrast must be precisely fit to create a seal.

Pleated filters can be a cost-effective alternative to replacing aging dust collectors often deemed necessary to meet tighter emissions standards. A filter swap can change the performance, seal better, and reduce the number of pulsing cycles needed. Dust conditions and media area can factor into performance and efficiency when moving from bag and cage to pleated filter elements. Parker engineers are available to discuss specific applications and, in certain cases, run simulations to determine how pleated filters might solve specific performance problems.

Dale Kadavy is senior product engineer, and Matthew Campbell is technical sales manager, Parker Hannifin. For more infromation visit parker.com/bha.

When To Consider A Pleated Filter

Typically, pleated filters offer advantages for applications with a current filter bag that is:

* Larger than 4 in. in diameter

* Shorter than 20 ft

* Handling free-flowing dust

Other situations--particularly those with sticky dust--require individual evaluation.

Pleated Filters: Fact or Fiction?

Pleated filters often get passed up due to their modest appearance or initial cost. In truth, pleated filters are efficient, versatile problem solvers.

Myth: Pleated filter elements don’t work in heavy industrial applications.

False. When properly selected and configured for the application, pleated elements work well in most industries and have eliminated many filtration bottlenecks.

Myth: Creating space below filter bags will cause performance issues.

Allowing more open space and a low air velocity zone with pleated filters will result in a larger drop-out chamber and reduce potential abrasion issues.

Myth: Pleated filters are more expensive.

Yes, a pleated filter with comparable performance costs more upfront. The savings come from lower operating costs due to lower pressure drop, reduced emissions, and quicker, less labor-intensive change-outs. In some applications, filter life is significantly longer.

Myth: Pleated elements are for highly specialized applications.

False: Pleated elements are suited to a wide range of dust collection applications, including food, pharmaceutical, wood, aluminum, cement, and steel processes.

Myth: It’s not long enough. It won’t work.

Looks can be deceiving. The pleated filter’s folded media design packs a lot of surface area into a small space. It can match bag performance with as little as one-third the length.

Myth: Pleated filters won’t fit a bottom-access design.

Not true. One-piece pleated elements can be installed easily via bottom access in place of a bag and cage filter.

Problem Solved: Maintenance and Efficiency Woes at High Efficiency Separator

On top of high differential pressure and high compressed air consumption, bag-style filters in the pulse-jet baghouse at a high-efficiency separator required replacement every two years, if not more often.

Replacing bags and cages with pleated elements increased the filtration surface area by 75%. This switch reduced differential pressure by 55%. Pulse pressure dropped from 100 to 60 psi, and pulse cycles could be extended from every 10-360 seconds. With less wear, filter life extended to more than five years.

Problem Solved: Brewer’s High Maintenance Hot and Humid Baghouse

A brewer’s outdoor pulse-jet baghouse has to endure the elements and is particularly vulnerable to hot, humid, and moist weather. As a result, crews had to check daily for baghouse operation malfunctions and conduct a complete bag change out every six months, significant skilled labor, downtime, and material expense.

Switching out the existing filter bags and cages with pleated filter elements increased airflow through the baghouse and reduced pressure drop, helping to extend filter life and minimizing maintenance. Compressed air use went from 95 to 60 psi, and specialized crews were no longer necessary for simplified filter changes, which took 75% less time to complete. Daily operation checks were no longer necessary, and the facility immediately tracked four months without an operational issue.

Of note, compressed air consumption varies in applications depending on pulse-cleaning regimens and filter media specifications. Parker technical account managers and application engineers can assess compressed air efficiency for specific applications.

You May Also Like