Valves, Gates, & Airlocks 108

June 6, 2007

Remanufactured Rotary Airlocks

Remanufactured Rotary Airlocks

These remanufactured rotary airlocks help customers meet or exceed OEM standards and are guaranteed to last as long as new OEM valves. By utilizing the principles of lean manufacturing, the airlocks are remanufactured in a time frame that meets customers’ lead time and saves them money. The company also specializes in solving problems that cause premature valve failures.

Rotary Airlock LLC, Rock Falls, IL. 800-883-8955 www.rotaryairlock.com

Pinch Valve

Pinch Valve

The Type A pinch valve features a full-port opening and straight-through flow path to eliminate turbulence when open. The simple two-piece body acts as a built-in pneumatic actuator. Fabricated elastomer sleeves offer maximum wear resistance and sealing on powders and entrapped debris. Double-wall and cone sleeves are available for extremely abrasive and high-velocity applications. The pinch valve is suitable for dense-phase pneumatic conveying of powders such as dry cement.

Red Valve Company, Inc., Carnegie, PA 412-279-0044 www.redvalve.com

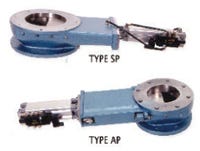

Slide Valves

Slide Valves

Britton Procol valves include six standard slide valve models ranging in sizes from 4 to 20 in. Type M, VN, S, A, and L valves are cast from either aluminum or stainless steel, providing a structurally sound body. Round flanges are standard, while square ones are available on some models. The design allows for clean operation and simple maintenance. The slide plates on all models are made of stainless steel. The type H valve has a heavy-duty mild-steel channel and is available in sizes from 6 to 20 in. While square flanges are standard, round ones are optional on special orders. Valves are available with pull/push, hand crank, pneumatic, or electric actuation.

SMS International Inc., Cortland, IL 800-296-1149 www.smsint.com

Airlocks

Airlocks

With larger pockets than other airlocks (up to 50% more volume), these airlocks can run at lower speeds, minimizing air leakage and providing longer life and a high return on investment. Operating tolerances are held to a minimum, ensuring maximum sealing under severe operating conditions. The airlocks are machined for actual operating temperature at no additional cost. Optional equipment includes inlet baffles, lantern rings for purging seals, a motion switch, a shear pin, and variable-speed drives. Rotor options include a standard eight-blade rotor, beveled rotor blades, a six-blade rotor with bolt-on wipers, L-slot wear bars, a closed-end rotor, and shallow pocket rotors.

Prater-Sterling, Bolingbrook, IL 630-759-9595 www.prater-sterling.com

Rotary Airlock Valves

Rotary Airlock Valves

MD rotary airlock valves for pneumatic conveying and gravity applications are available in cast iron and stainless-steel construction. They feature a heavy-duty housing with ANSI flanges and close-tolerance machining of internal surfaces, providing an effective seal. The valves are suited for pressure differentials up to 15 psi and are available in sizes from 4 to 16 in. An optional full-length bolt-on housing inspection door is available.

ACS Valves, Caledonia, ON, Canada 800-655-3447 www.acsvalves.com

Rotary Valve Bottom-Mount Slide Rail

Rotary Valve Bottom-Mount Slide Rail

Rotary valves for pneumatic- and gravity-conveyed powders are now available with Easy-Slide Rotor Support (ESRS) bottom-mount slide rails that safely support valve components when they are removed from the valve bore. The support protects these process-critical components and keeps them precisely aligned for assembly. It also simplifies cleaning and inspection by allowing the operator to pivot the rotor and end plate up and out of the way. The ESRS assembly maintains critical tolerances for years and features heavy-duty construction, hard-chrome slide rods, and precision linear bearings. It also allows for removal of the end plate only or the complete rotor and end-plate assembly. When the complete assembly is removed, the rotor can be separated from the end plate, allowing access to the shaft seals.

Nu-Con Equipment, Chanhassen, MN 877-939-0510 www.nucon.com

Fabricated and Machined Airlocks

Fabricated and Machined Airlocks

Rugged airlocks are available in customized fabricated and machined models for pneumatic systems, gravity feeds, and volumetric discharge devices. Fabricated models handle dust collection, plastics, feeds, and corrosive chemicals where pressure differentials are 20 in. of water column or less. Urethane wipers provide a tight fit between fabricated rotors and housings. Machined airlocks have cast housings for added durability and are designed for higher pressures as well as difficult and abrasive materials. Rotor to housing fit is a tight four- to six-thousandths of an inch. Both models offer carbon and stainless-steel rotor and housing options.

Airlanco, Falls City, NE 800-500-9777 www.airlanco.com

Plug Diverter Valve

Plug Diverter Valve

This new diverter valve with aluminum hard-coated housing and rotor is designed for use in gravity or pneumatic conveying applications for plastic pellets and other granular products. The heavy-duty valves are available for surge pressure up to 90 psi in sizes from 3 to 12 in. Features include seal rings at each port, full round pass-way design, a closed-end rotor, 45° flow direction, differential pressure up to 60 psi, high temperature on request, manual or pneumatic operation, and a heavy-duty pneumatic actuator with integrated mechanical stops.

Pelletron Corp., Lancaster, PA 717-293-4008 www.pelletroncorp.com

Inflatable Seated Butterfly Valve

Inflatable Seated Butterfly Valve

This inflatable seated butterfly valve is suited for abrasive materials such as sand, feldspar, fly ash, and most other dry, granular materials that reduce valve life. The inflatable seat design provides a better seal by utilizing air pressure to expand the seat against the disk, providing more sealing area and an even pressure distribution against the disk. The seat automatically compensates for wear when it inflates against the disk, extending valve life. Standard sizes range from 2 to 30 in., and the valve is available in a wide variety of construction materials, including stainless steel and aluminum.

Posi-flate, St. Paul, MN 651-484-5800 www.posiflate.com

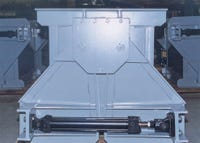

Clamshell Gates

These clamshell gates have a rugged design and offer limited entrapment areas for material to hang up. They are typically used for cutting off or regulating material flow when loading hopper, bins, conveyors, and other containers. The dual cylinder version optimizes structural integrity and closing force. Optional seals can be purchased for fine or wet materials.

Pebco Inc., Paducah, KY 270-442-1996 www.pebco.com

You May Also Like