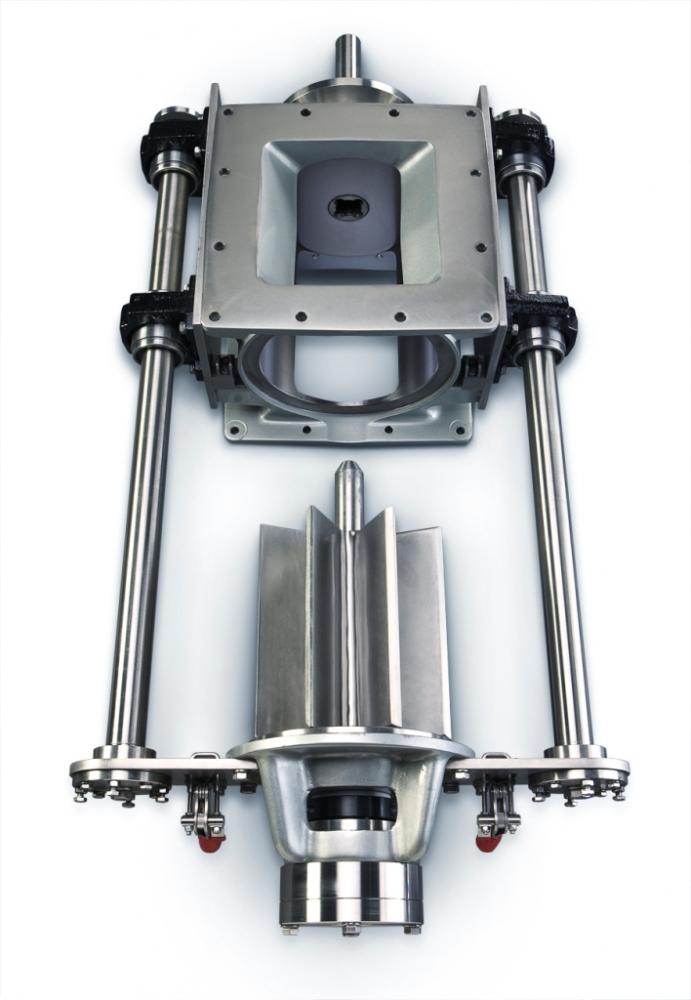

Run-Clean Rotary Valves

November 19, 2012

Designed specifically for sanitary applications, such as food processing, pharmaceutical processing, and chemical or plastics applications, the Run-Clean series of rotary airlock valves are designed with multiple features that reduce material buildup inside the valve housing that can occur during operation. These features include: angled surfaces and rounded edges inside the housing to eliminate dead zones and ensure optimal material flow; factory-applied internal surface coatings, such as tungsten, to prevent surface wear imperfections where material can buildup; glandless, sleeve-style shaft seals that prevent contaminant migration into the housing; stainless steel housings cast in North America to ensure superior strength in the composition and solidification of the housing’s metallurgy. The stainless steel housings are then CNC-machined to precise tolerances; and, with internal surfaces polished to a No. 4 finish, the ACS Valves design eliminates internal crevices and joints, common with conventional cast housings and bolt-together designs, where contaminants can accumulate. By reducing the accumulation of material inside the valve during operation, the Run-Clean series reduces total time for cleaning, validation, and inspection of the valve, and therefore, speeds the return to service of the valve.

ACS Valves, Caledonia, ON, Canada 800-655-3447 www.acsvalves.com

You May Also Like