7 Pneumatic Ways to Control a Slide Gate

When controlling dry bulk solid material flow, there are varying controls that can meter the volume and flow rate.

April 21, 2021

Austin Anderson, content marketing manager, Vortex Global USA

In most bulk powder handling applications, slide gates are predominantly used to either completely shut off or completely open the flow of material. In some instances, it may become necessary to limit the amount of material that is allowed to pass through the gate. When controlling the flow of dry bulk solid materials there are varying controls that can be used to meter the volume and flow rate.

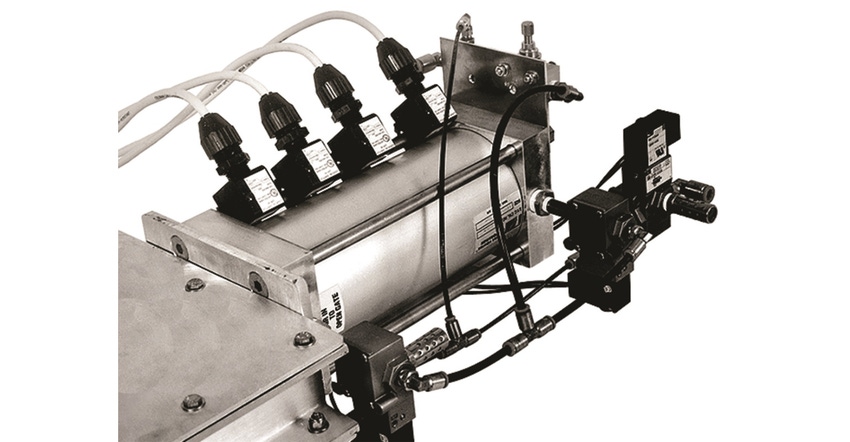

Flow controls are components that can be added to a pneumatic actuator to assist in controlling material flow. Pneumatic actuators are more cost effective than electric actuators and are able to quickly reposition the blade. Comprised of an air cylinder, piston/diaphragm, rod, and valve stem, pneumatic actuators can also be modified to include a material flow control device to assist in providing the accurate metering of material.

These accessories are especially beneficial in applications that include:

Loss-in-weight feeders

Material metering

Truck and/or railcar loadout

Dribble flow

Scaling operations

Batching ingredients

Maintaining flow rates

Implementation of material flow controls and accessories can lead to improved accuracy with precise batch weight calculations whether filling small bags and/or containers or topping off trucks on scales. Other benefits include the reduction of fill times between workstations, and control flow when handling floodable materials which can fill rapidly.

1. Adjustable Variable Positioner (AVP)

The most commonly used and customizable material flow control assembly is the AVP, because of this it is the most universal option for material flow control. Unlike other options, the AVP can control flow on both the opening and closing strokes. The AVP is an extremely cost-effective option and offers highly accurate positioning up to 3/16 of an inch.

The AVP has the ability to accommodate numerous intermediate positions. The number of intermediate positions is determined by the number of magnetic reed switches which are mounted to the (pneumatic) actuator. The number of AVP intermediate positions is only limited by magnetic reed switch size, available space along the pneumatic actuator’s tie rods, and ensuring the sensing ranges of the magnetic reed switches do not overlap. An AVP requires a Programmable Logic Controller (PLC).

2. Infinite Variable Positions (IVP)

Contrary to other material flow control options, the IVP allows for the total control of variable positioning on both opening and closing strokes. The IVP relays blade position feedback along the entire stroke of the blade by utilizing a linear output transducer. A key benefit of the IVP’s immediate feedback capability is the option for a gate to be moved into any position at any time.

A control box or PLC is used to operate the gate which can be manually operated at the valve or synchronized with a PLC to automate operations. The IVP’s variable positions are adjusted utilizing technology unlike other material flow control assemblies.

Common applications for IVP are those in which accuracy of material flow needs to be the most precise. In these cases hitting the exact weight of a bag or container is crucial as being off by a small fraction can be costly to the company.

3. Variable Position Open (VPO)

In the VPO configuration a gate can begin in the closed position, actuate into a variable position on the opening stroke, then return to the full closed position or continue to the full open position. The VPO is not backwards compatible. If the blade is in the full open position, it cannot be actuated into a variable position on the closing stroke. First it must be actuated back to the full closed position before it can then reopen into a variable position. If needed, the VPO also allows traditional full open-to-full closed actuation, and vice versa. The VPO is useful during applications that involve dribble flow metering.

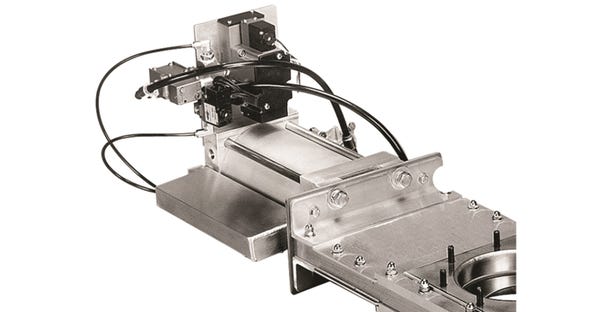

4. Control Variable Position Open (CVPO)

The CVPO modification is ideal for use in applications in which there is a need to limit the full open position to avoid flooding processes downstream. A threaded rod is included at the cylinder housing’s end on the air cylinder itself with the CVPO modification. Manual adjustments can be made to the threaded rod to limit the opening stroke of the blade. When utilizing the CVPO option, the full open position of the blade becomes the setpoint established by the threaded rod.

CVPO is only used in applications where a client needs to limit the opening stroke. Due to the manual nature of this material flow control, changes are infrequent.

5. Variable Position Closed (VPC)

In the VPC configuration a gate can begin in the open position, actuate into a variable position on the closing stroke, then return to the full open position or continued to the full closed position. Like the VPO configuration, the VPC is not backwards compatible. If the blade is in the full closed position, it cannot be actuated into a variable position on the opening stroke. First it must be actuated back to the full open position before it can be reclosed into a variable position. The VPC also allows traditional full open-to-full closed actuation, and vice versa. This is another flow control device that is useful in dribble flow metering.

6. Variable Position Open – Variable Position Closed Assembly (VPO-VPC)

The VPO-VPC configuration is used in applications that require control of the blade’s open and close positions to achieve a dribble feed of material. This assembly combines the aspects of the VPO and VPC controls to allow for the manual adjustment of the intermediate blade position by implementing air control solenoids and a pneumatic trip switch.

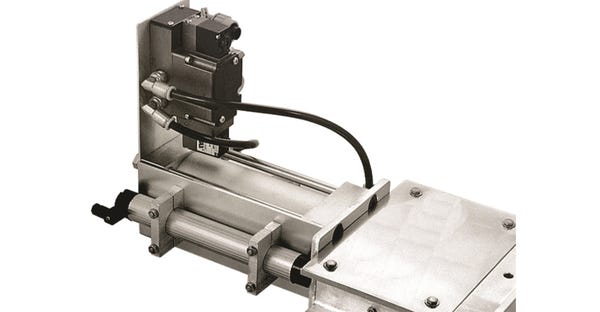

7. Two-Stage Air Cylinder

The two-stage air cylinder is designed with a magnetic piston to accommodate magnetic switches, for position indication. Most suitable for applications in which the blade needs to stop at the same exact intermediate position each time, the combined cylinder provides blade positioning at three positions: blade open, blade partially open, and blade closed. Two-stage air cylinders are commonly used with three-way diverters in which the stroke needs to be exact to accommodate the middle position.

Manufactures of slide gates can assist in evaluating which material flow control options is best suited for your specific application. Many details need to be evaluated to determine the best option including characteristics of the materials behind handled and the location of the gate control within the system.

Austin Anderson is content marketing manager, Vortex Global USA (Salina, KS). For more information, call 888-829-7821 or visit www.vortexglobal.com.

You May Also Like