Demystifying Bin Vibrator Selection

February 24, 2009

By David Ruggio

|

Exploded view of electric eccentric vibrator |

Material flow problems in bins, hoppers, and silos (hereinafter referred to as “bins”) are common. These problems are caused by a high level of friction between the material and the bin wall, and high cohesive strength within the material. Wall friction is dependent upon the wall angle, wall material, smoothness, temperature, moisture, corrosion,

abrasive wear, and the time the material remains at rest in the cone where the problem exists. Cohesiveness is affected by material properties, including moisture content.

Flow problems can occur, such as bridging or ratholing. Solving these problems is essential for efficient production and accurate material inventory management. In many cases industrial vibrators are employed to break the friction between wall and material, as well as material cohesiveness, to promote material flow from the bin.

Industrial Vibrator Types

There are two basic types of industrial vibrators: rotary and linear. Rotary vibrators are characterized by an unbalanced mass rotating around a center point. The result is a centrifugal force output at a given frequency. Rotary vibrators include ball, ring, turbine, and motor-driven eccentric types.

An unbalanced mass is useful for calculating the centrifugal force output, and it is used for sizing a vibrator for use on a bin. It is even used for sizing applications, such as vibratory screens and feeders, with a known feed rate.

Rotary vibration is best applied to drier products that tend to bridge and rathole. The objective with rotary vibration is to make the bin wall as rigid as possible and transmit vibration directly into the

material. A rigid mount will help keep the frequency and force output higher, thereby making the vibrator more efficient.

Linear vibration is obtained by oscillating a mass back and forth on one axis, which results in force output (impact) as the piston decelerates and changes direction at the end of each stroke. Three types of linear vibration exist: continuous impacting, continuous nonimpacting, and single impacting. Continuous impacting are those which oscillate continuously and provide an impact similar to a blow from a hammer at the end of each stroke. Continuous nonimpacting vibrators have the same continuous operation, but there is no impact.

The vibrator provides a force output due to negative acceleration of the piston at the end of each stroke. The piston is stopped by an air cushion rather than the base plate. The single impacting design provides one impact each time the solenoid is energized.

Linear vibration is best for promoting flow of moist or wetter materials. The objective is to move the wall back-and-forth (“oil canning”). This movement is beneficial for dislodging wet, sticky materials from the bin wall.

Electric or Pneumatic

|

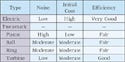

Table I: Comparison Chart |

You should consider the following during vibrator selection: noise level, efficiency, life, maintenance, initial cost, and operating cost.

Electric vibrators are the most efficient, have the longest life, low maintenance, and low noise. However, the initial cost for an electric vibrator is higher than for pneumatic vibrators. Turbine vibrators are the most efficient and quietest of the pneumatic designs, which makes them best where low noise, high efficiency, and low initial cost are required.

Common electric motor-driven vibrators are those that use a motor with its shaft extending out of both ends of the housing with eccentric weights on both sides. These vibrators operate at a variety of frequencies, commonly 850, 1170, 1800, and 3600 rpm. Voltages for electric vibrators include 115 V ac/single-phase/60 Hz; 230 V ac/single-phase/60 Hz; and 230–460 V ac/three-phase/60 Hz.

Selecting a Vibrator

Selecting the best vibrator for your bin flow application requires knowing a few rules of thumb, plus a little field experience.

When applying a bin vibrator, it is important to understand the problem:

Is material ratholing or bridging?

Is material sticking to the walls of the bin?

Is the material wet or dry?

The answers will determine whether a rotary or linear design is best. Also, what power source will you use, electric, pneumatic, or hydraulic? The decision may be simply what is available.

Rotary Vibrators

|

Exploded view of turbine vibrator |

Rotary vibrators are typically used with dry materials. To move material in a bin, the friction between the material and the bin wall has to be overcome. Once overcome, the material cannot cling to the bin wall, as it must flow. The force required to accomplish this for dry materials is a 1:15 ratio of the vibrator force to material weight contained in the cone section of the bin.

First, calculate the weight of the material in the transition part of the bin. Normally this is the only place where the friction between the material and bin wall needs to be broken. Do not calculate the total weight of material in the bin, only what is in the cone or transition part. The equations for calculating the volume of typical cones are as follows:

Cylindrical Volume = 1⁄3 × π x D × D—4 × H

Rectangular Volume = 1⁄3L × W x H

These formulas are not exact because of the diameter of the discharge opening in the cone section, but they are simpler and close enough for what needs to be accomplished in sizing the vibrator. Once the volume is calculated, the weight of the material in this transition section can be determined by multiplying the volume by the material bulk density.

Now the force output of the vibrator required can be determined, based on the 1:15 ratio (dry materials). Example: the cone section of a 25-tn cylindrical bin contains 7000 lb. Dividing 7000 by 15 indicates that a vibrator producing ≥470 lb of force is needed. Most vibrators are adjustable, by varying the eccentric weight, air pressure, etc. It is a good idea to oversize the vibrator to make sure it is powerful enough, as reducing vibrator output is easier than remounting a larger one.

Sometimes bins with a 10 ft or larger diameter may need two vibrators, each on opposite walls or 180 degrees apart, for better transmission of vibration into the material. Determine the force output required, then divide by two to determine the force output for each vibrator. This places less stress on the bin wall for applications requiring very high force output.

Linear Vibrators

Linear vibrators are the best choice for wetter materials due to the high-energy output in one direction. Linear vibration will flex the bin wall in and out, which is best for removing wetter material from the bin walls. Nonimpacting types are best, when possible, because they produce lower noise than impacting vibrators.

Linear vibrators are sized by knowing the force output (nonimpacting types) or the bin wall thickness (impacting types). Determining a force impact value from impacting vibrators requires testing with sophisticated equipment that can measure high forces over short periods of time, which is characteristic of an impacting vibrator. First, the acceleration of the piston must be determined. Then, knowing the mass of the piston, the force output can be calculated.

Linear vibrators are best sized by the wall thickness of the bin. The vibrator will clean approximately a 4–6-ft area. It may be necessary to apply several linear vibrators when the entire bin must be cleaned. If the object is to maintain material flow only, fewer vibrators may be used. Use the following guidelines for impacting vibrators:

Wall thickness of 0.7 to 0.125 in.; use vibrator with 1¼-in. piston

Wall thickness of 0.125 to 0.25 in.; use vibrator with 2-in. piston

Wall thickness of 0.25 to 0.375 in.; use vibrator with 3-in. piston

Wall thickness of 0.375 to 0.5 in.; use vibrator with 4-in. piston

If using a nonimpacting design, choose a model with the next larger piston.

Moisture Content

Moisture affects the cohesiveness of the material and the friction between material and bin walls. As moisture content increases so does the cohesiveness of the material, as does the materials’ tendency to form cohesive arches or bridges. Only when the moisture content approaches saturation does the cohesive strength decrease. At this point the material behaves like slurry.

Relative humidity influences the moisture content of the material, especially with materials that are hygroscopic. Hygroscopic material increases in moisture content with increases in humidity, which in turn increases cohesive strength, and results in the likelihood of material flow problems.

Material with moisture content ≥5% is considered wet. Wet materials require more force output to move. Don’t know the moisture content percent? Consider “Dave’s Rules” for moisture content:

Throw a handful of the material against the wall: If some of it sticks to the wall in clumps, then this material is “wetter.” If not, then proceed to the next question.

Can you squeeze a handful of the material and have water leak out in your hand? If yes, this is a “wetter” material. If no, proceed to the next question.

Can you squeeze a handful of material into a snowball? If no, this material is “drier.” If yes, proceed to the next question.

If the handful of material clumps together into a snowball, does it remain clumped when you flick it with your finger? If yes, then the material is considered “wet.” If not, then the material is still considered somewhat wet and additional force output from the vibrator may be required.

These guidelines will qualify whether the material is drier or wetter, and whether a rotary or linear vibrator is best. But the distinction is not always black-and-white. There is a gray area in the selection process. Rotary vibrators are commonly used with wetter materials because of the noise and inefficiency of linear types. Only rotary vibrators in the 1800-rpm range should be considered for materials that are not dry. The force output should be increased by 5% for each percentage of moisture content. For example, the force output for use with material that has 5% moisture content would be increased by 25%.

Vibrator Mounting

A pneumatic rotary vibrator will operate at the natural resonant frequency of the bin wall. An electric vibrator operates at its designed rpm, assuming its horsepower is high enough to bring it through the resonant frequency of the bin wall. With rotary vibrators, the bin wall needs to be as stiff as possible to transmit the vibration through the wall and into the material. Moving the wall back and forth (oil canning) with rotary vibration proves to be inefficient and may damage the vibrator.

The mounting for linear vibrators is different. If vibrating dry material, you should use the same guidelines given for a rotary vibrator. For wet materials that stick to the bin wall, use a mounting channel 12–18 in. in length. This will allow the linear action to flex the wall, which is required to remove sticking material. Linear vibrators will operate at their own frequency depending on the air supply pressure. They are less affected by the natural frequency of the bin wall.

Conclusion

Material flow problems exist for many reasons. Solving them is not always easy. Industrial vibrators, when properly selected, offer an effective and high-value solution. Many designs exist and each provides a unique solution. Defining your needs and choosing a vendor with a wide selection of vibrator technologies and the depth of knowledge are keys to finding long-term solutions.

David Ruggio is senior application engineer and customer technical adviser for vibration technologies at Cougar Industries Inc. Ruggio has a degree in applied science and can be reached at 800-262-2106 or [email protected].

You May Also Like