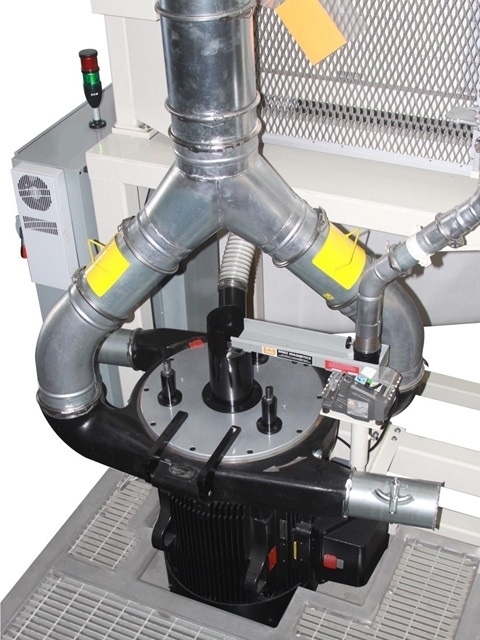

Pulverizing Mill Has Dual Air Inlets

March 6, 2017

The newly designed PKA Velocity Series mill now has dual air inlets controlled by air damping valves to control the volume of air intake and double the amount in the mill’s cutting chamber. The mill also has dual material outlets which takes the material out of each side of the mill to reduce residence time and heat build-up in the mill. The direct drive mill is powered by a 150-hp motor that is driven by an inverter drive mounted into the control panel of the machine for the mill motor.

“We are always conscious about power demands and costs of operation,” said president and owner of Powder King, Jim Hummel. “This is why an inverter drive is used. The start-up of this motor only draws 50-55 amps at start-up of the mill, unlike other starting methods utilized by other machines that causes huge power draws and spikes in customer’s electrical demand, and dramatically increases the cost of electrical usage for our customers. The inverter drive also serves other purposes in our system, like adjusting the tip speed of the mill’s disks should control be needed to alter grinds of some resins. This is an added feature I don’t think others think about when versatility is needed in some cases.

Powder King, Anthem, AZ 623-551-9897 www.powder-king.com

Click here for information about the PBS Toronto event, May 16-18, 2017

For related articles, news, and equipment reviews, visit our Size Reduction Equipment Zone

Click here for a List of Size Reduction Equipment Manufacturers

You May Also Like