Pneumatic Vacuum Conveying of Pharmaceutical Powders

January 4, 2012

By Sharon Nowak, K-Tron

|

Photo 1: K-Tron pharmaceutical design vacuum receiver |

Powder transfer by pneumatic vacuum conveying has become one of the more popular means of transport for a wide variety of pharmaceutical, nutraceutical, and food materials. The gentle use of vacuum in either dilute or dense phase ensures that the powder or granulate remains within the process, as opposed to leaks or losses that are often results of positive pressure transfer systems. The use of either dense- or dilute-phase vacuum can be applied to a wide variety of pharmaceutical operations including the loading of blenders, sifters, mills, capsule fillers, tablet presses, and even finished tablet and capsule handling without damage to the finished product.

In addition, the relatively tight space limitations in many pharmaceutical processing suites often presents a challenge in the delivery of powders or powder blends to pharmaceutical processes. Pneumatic vacuum conveying offers a solution to these space limitations.

Vacuum conveying operations can often be incorporated directly into the secondary process in an effort to ensure a closed and leak-free operation, without any exposure of operator or product. These additional processes include, but are not limited to: direct blender loading; inline conical screen milling or sieving; tablet press loading; granulator loading/unloading; fluid bed dryer unloading; tablet/capsule conveying; refill of screw feeders for loading of continuous processes such as granulation, mixing, milling/micronization, and extrusion; transfer direct to feeders for batch weighing or dispensing of several components in a blend.

Conveying and Dispensing of Pharmaceutical Powders

Vacuum transfer systems can easily be adapted for pickup of material from a variety of sources. These sources can include open drums (for nonhazardous materials) whereby the pickup mode is made by means of a pickup wand. In cases where higher containment is required, specialty glove box design pick up bins can be incorporated into the vacuum line in order to protect both the operator and the product as shown in Photo 2.

Dilute-Phase Principle of Operation

|

Photo 2: Contained glove box pick up for vacuum transfer |

Most vacuum transfer operations operate via the dilute-phase principle of powder transfer. Typical dilute-phase conveying operations involve materials where segregation in the conveying line is not a concern. Comparative velocities in a 3-in. pipe for dilute phase can range from 3000 to 7000 ft/min. In most applications the gas is air. However, in the pharmaceutical industry, nitrogen is also widely used due to its inerting capabilities as well as the natural purity of the gas.

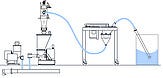

As illustrated in Figure 1, in a typical conveying cycle, after the vacuum source is initiated, the material is delivered direct to a vacuum receiver which allows for the break of the vacuum and the release of the material from the gas stream. This receiver includes a reverse-jet filter that is pulsed when the vacuum breaks to allow for cleaning of the filter media. The outlet of the receiver includes a valve, which is chosen based upon the material characteristics and process requirements. Typical valve types include butterfly valves, (both single and split butterfly for high containment), pneumatic flaps, and rotary valves. The discharge valve is sequenced to open after the vacuum breaks and the filter has been pulsed, thus delivering product to the process below.

The source of vacuum for the process can be either a venturi type device or a vacuum pump. When sizing the vacuum source, the complete system is reviewed, inclusive of the pressure drops throughout the process equipment in question. In addition, an inline HEPA (High Efficiency Particle Assay) filter is usually also used at the exhaust of the receiver, in order to protect the pump from any dust which may bypass or penetrate the primary filter in the receiver and avoid any release of this dust in the pump exhaust.

Air Swept Sieving (Check Screening)

|

Figure 2: Principle of air swept sieving |

Vacuum conveying is often used for such operations as feeding of conical screen mills and in-line sifting in order to improve throughput of the process, contain dust or exposure, and also to assist in improvement of end product quality. This principle is referred to as air swept sieving or check screening, and is usually performed using a dilute-phase vacuum stream.

When conveying with a process in line, the equipment in question must be sealed and suitable for operation under vacuum. Such equipment includes in-line deck or rotary sieves/screeners and conical screen mills.

In each of these cases, the material can be delivered from a variety of sources, including drums, bag dump stations, IBCs, or other processes (such as the fluid bed dryer as illustrated in Figure 2.) Material is then conveyed through the equipment and into the vacuum receiver described above.

In the case of conical screen mills, the operation under vacuum can actually improve the quality of the product. Since all milling is based upon actual residence time in the mill, the use of operation under vacuum actually gets the product in and out quicker. This reduces the attrition that may be applied toward the product by added circulation in the milling chamber, thus reducing the amount of fines/dust produced by the mill, and improving the overall particle size distribution of the end product.

The same principle for improved product quality and output also applies to in-line sieving operations by reducing overall residence time and avoiding product attrition and product degradation.

Pneumatic Vacuum Receivers as Refill Devices for Loss-in-Weight Feeders

|

Photo 3: Conveying through two inline conical screen mills |

As mentioned above, pneumatic receivers, which operate under a dilute-phase vacuum transfer principle, are often used as refill devices, particularly for continuous operations. The operating principle of the pneumatic receiver showing a simple flap valve is shown in Figure 1. The pneumatic system utilizes negative pressure to suck the material required to refill into a separate mounted and supported vacuum receiver. The receiver is filled to a determined level and then holds this material charge until the feeder below requests a refill. The level of fill in the receiver is determined by level sensors. At the point of refill request by the feeder below, the discharge valve opens and the receiver contents are discharged into the feeder hopper. For LIW feeding, this discharge valve is always a pneumatic butterfly valve in order to prevent any chance of dribbling (as shown in Photo 4). At the time of this release, a gas pulse is sent through the filter housed in the vacuum receiver, in order to release any entrained particulate or material that may have settled on the filter. The filter material can vary, including options on laminated membrane type materials, for quick release and easy clean properties.

After dumping the material into the feeder hopper below, the valve is shut again and then the receiver vacuum cycle immediately begins, in order for the pneumatic receiver to be instantly ready for the next refill request.

The use of pneumatic receivers as refill devices allows for an uninterrupted source of refill from bags, drums, IBCs, or super sacks.

Alternate Conveying for Pre-blended or Fragile Materials: Dense-Phase Vacuum

The lower gas velocity used with dense-phase conveying means the force exerted on the conveyed powder or granulate is much gentler. This gentle action also reduces the segregation issues often experienced with the more aggressive dilute-phase operation. It should be noted, however, that there are limitations to dense-phase conveying. These limitations include conveying distances in excess of 12 ft vertical and 15 ft horizontal, and conveying materials that are cohesive, hygroscopic, or so coarse in particle size that they will not readily form slugs.

Dense-Phase Principle of Operation

|

Photo 4: Pneumatic receivers as refill devices for loss-in-weight feeders |

By definition, dense phase means a higher product to gas ratio, or a smaller amount of gas is used to move a large quantity of product. The less the gas requirement, the less the power consumed by the exhauster or vacuum pump. Typically material is picked up from the outlet of a specialty hopper, which creates a pressure differential and allows slugs of product to form, as illustrated in Figure 3. In addition, the hopper also includes a type of makeup air inlet, which aids in the forming of the slugs as they travel and pulse through the conveying line. The combination of the relatively low air velocity and an expanded line size results in a type of “siphon-like” effect for conveying to the vacuum receiver, with less resultant attrition and segregation.

Regardless of the type of conveying technique used (dilute or dense); the material is delivered direct to a vacuum receiver which allows for the break of the vacuum and the release of the material from the gas stream. This receiver includes a reverse-jet filter, which is pulsed when the vacuum breaks to allow for cleaning of the filter media. The outlet of the receiver includes a valve, either flap type or butterfly. This valve is sequenced to open after the vacuum breaks and the filter has been pulsed, thus delivering product to the process below.

Conveying Capsules and Tablets

Pneumatic vacuum conveying can also be used for transfer of filled capsules or tablets. However it should be noted that this type of conveying typically requires special modifications to the pneumatic receiver in order to avoid any damage to the product. Due to the individual particle density of filled capsules or tablets, and their overall higher mass, a lower overall velocity of the individual tablet results. In other words, a small granulate weighing much less will move a lot faster in equivalent gas velocities than a tablet the size of an aspirin. In order to balance the higher required gas velocities, the inlet to the receiver is tangential and expanded, to allow for a natural deceleration of the product before it enters the receiver. In addition, the receiver is often lined with a soft FDA-approved rubber liner to avoid any product degradation that could occur if using a standard stainless steel receiver, as illustrated in Photo 5.

Cleanability of Design: A Key Advantage in Pneumatic Transfer

|

Figure 3: Dense-phase conveying principle |

Today’s pneumatic vacuum receivers are available in a variety of executions with designs suitable for easy cleaning and to ensure accessibility for operation and maintenance, as shown in Photo 6. Typically, pneumatic components, such as receivers and pickup hoppers are equipped with flanges affixed by sanitary triclover type clamps, resulting in disassembly without tools. All system components are designed to ensure the optimum in powder handling specific to the process requirements. Specialized options in wash-in-place designs with retractable spray ball devices, swing out filter heads for height restrictions, and HEPA filtration are all available depending upon the application and process. In many cases full riboflavin testing can be done to ensure complete coverage by the retractable spray balls for the wash-in-place option. In addition, the use of split butterfly containment valves at the receiver outlet can easily be integrated for direct contained connection and decoupling from the vessel or IBC below. All pneumatic solutions, including the product pickup option, are engineered with operator and product safety, superior ergonomic design, and ease of maintenance in mind.

Primary and Secondary Filtration Options

|

Photo 5: Capsule conveying receiver |

The primary internal filter of the vacuum receiver is an essential component because it prevents dust and/or finer particles from being sent to the vacuum pump or secondary filter. It is important when discussing both the materials of construction of this filter media and also the porosity, to evaluate the complete particle size distribution of the powder or blend to be transferred. For example, when transferring a blend that may contain a small percentage of very fine API component, it is essential that the filter media porosity be small enough to prevent sending a large percentage of this material directly through the filter media, as opposed to going into the necessary process. There are a variety of filter media and porosities available, depending upon the system and material requirements. These same rules apply to the secondary filter, which is often used after the receiver to prevent any dust from going to the pump and out of the exhaust. These types of filters typically include HEPA type media, and may also be bag-in/bag-out types, in order to ensure complete containment when opening the system for filter removal and/or replacement.

Conclusion

|

Photo 6: K-Tron pharma receivers and loss-in-weight feeders |

Vacuum conveying for pharmaceutical operations offers advantages for material transfer including cleaner, dust-free, and contained operation with minimal product exposure. It also offers a gentle method to move a large volume of powders especially in areas with height limitations, where gravity discharge from a large bin or tote may not be an option. Finally, the option to use either dense- or dilute-phase vacuum transfer offers much more versatility in powder transfer. Both individual ingredients, as well as powder blends, can be conveyed without worry of segregation or attrition on the product. For these reasons, pneumatic vacuum conveying, via dense- or dilute-phase, is obviously the logical choice for efficient powder transfer.

Sharon Nowak is business development manager: food and pharmaceuticals for K-Tron (Pitman, NJ). Nowak has a 26-year background in the process equipment industry for food and pharmaceuticals, as well as a degree in Biochemical Engineering from Rutgers University. For more information, visit www.ktron.com.

About the Author(s)

You May Also Like