Gyratory Sifter Eliminates Production Problems for Processing Plant

October 19, 2010

An Ohio blender of breadings and mixes had four CS-1 gyratory sifters from Sifter Parts & Service Inc. in operation in its processing plant. The sifters were set on platforms approximately 4 ft off the ground to accommodate the flow of product from the blender into the sifter. The elevated height of the sifters, however, made it difficult for the maintenance crew to efficiently change out the screens.

|

Screen area through porthole: Viewports on the CS-1 sifter provide 100% screen visibility. |

While visiting a large trade show, the plant manager happened to see a rotary sifter exhibited. He thought the design of the rotary sifter would make it easier and quicker to change out screens. After talking with the manufacturer of the rotary sifter, the plant manager decided to test one of the rotary sifters in his plant.

The unit performed well during the test and, shortly afterward, the processor purchased four rotary sifters and placed three into operation. After approximately a month in service, the rotary sifters were not performing up to expectation and the fourth sifter was not added to the production line. It soon became evident it had been a mistake to install them, but after the large expenditure on the new machines, the plant manager was committed to making them work.

|

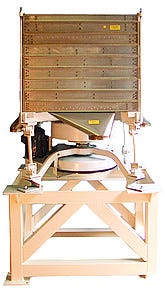

CS-1 Sifter: BISSC-certified CS-1 sifter offers proven reliability. |

Following a routine change of the screens from one mesh size to another, a large rip was discovered in one of the nylon reel screens. The impellor on the rotary sifter had forced a foreign object through the screen. All product that had been processed since the last time the screen was known to be undamaged had to be discarded – an extremely costly proposition. The plant manager then replaced the nylon reel screens with reel screens manufactured from stainless steel. The stainless steel reel screens did not flex as the nylon reel screens did and the rotary sifters could no longer handle the volume required. As a result, a lot of good product went into tailings.

After about a year in service the rotary sifters were replaced with one of the old gyratory sifters that had been placed in storage along with two new Model CS-1s. The CS-1 gyratory sifters were installed at ground level and the length of the transfer sleeve from the blender into the sifter was lengthened approximately 3 ft.

|

Screened insert frame: No glue, drying time, or tensioning is required to replace screens on the CS-1 sifter. |

The plant manager reports the CS-1 sifters have been performing well in their production line, the passive gyratory motion is much gentler on the product than the impeller on the rotary screen, they are getting better capacity, and no contaminants or foreign objects are pushed through the screens. The CS-1 offers greater variety from one sifter by simply adding or removing screen decks and since the CS-1 sifters were lowered to ground level, screen change outs are much easier and quicker. Additionally, with the modification of optional portholes in the screen decks, virtually 100% of the screen area can be visually inspected without disassembling the deck stack.

For more information on Sifter Parts & Service Inc. (Wesley Chapel, FL), visit www.sifterparts.com

You May Also Like