Are Dust Collection Filters Costing You?

August 3, 2007

|

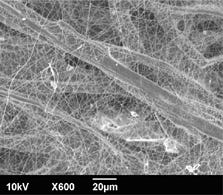

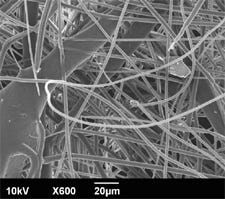

UAS nanofiber filter at 600× magnification |

How often has buying on price come back to bite you? Probably as often as off-brand batteries that die after just a couple of days, the cheap shirt that falls apart after the first wash, or the “bargain” used car that spends more time in the shop than on the road.

Smart consumers know that a true evaluation of cost requires looking beyond the initial purchase price. In the case of dust collection cartridge filters, buying based on the total cost of ownership can translate into thousands of dollars in long-term savings through fewer filter replacements, reduced maintenance, and less energy use.

The Best Versus the Rest

The three main types of standard cartridge filters are cellulose filters, cellulose blended filters with a synthetic fiber (referred to as blended cellulose), and cellulose filters with a nanofiber layer. Cellulose and blended products range in price from $50 to $75 per cartridge. Filters using a nanofiber layer are in the $100 to $110 range. Why are nanofiber filters more expensive and what makes them worth the price?

Cellulose filters with nanofiber technology use a microscopic layer of fibers 1000 times smaller than the diameter of a human hair to create surface loading of dust particles. When dust particles accumulate on the surface of the filter, they can be easily pulsed off during the cleaning process. Because dust is not embedded in the media substrate (the material beneath the nanofiber) as with depth-loading cellulose and blended-cellulose filters, nanofiber filters stabilize at a lower pressure drop level, increasing fractional efficiency dramatically and maximizing filter life.

In contrast, some cellulose or blended-cellulose filters on the market have an outer layer of melt-blown fibers to increase the filter’s efficiency and life. The principle is the same as adding a nanofiber layer—to provide more surface loading so that the filter is easier to pulse clean. However, melt-blown fibers and nanofibers have different diameters and layer depths.

|

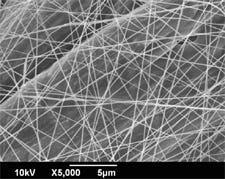

UAS nanofiber filter at 5000× magnification. Because nanofiber is effective at capturing even the smallest dust particles, only a very thin layer, about 0.1- to 0.5-µm thick, is needed. This meshlike surface is extremely efficient in filtering even submicron particles (less than 1 µm) from the contaminated airstream. |

Melt-blown fiber diameters measure approximately 10 µm. Nanofiber diameters can be more than 100 times thinner, ranging from 0.07 to 0.15 µm. These very thin fibers are produced using an innovative electrostatic process that produces the finest synthetic fiber used in any current filtration product. These thin fibers form a permanent meshlike surface with exceptionally small openings, or pores. These tiny openings are extremely efficient in filtering even submicron particles (less than 1 µm) from the contaminated airstream.

The nanofiber layer is also about 100 times thinner than that of the melt-blown fiber. Because nanofiber is so effective at capturing even the smallest dust particles, only a very thin layer, about 0.1 to 0.5 µm thick, is needed. In comparison, a melt-blown layer is about 50 µm thick. The added thickness of the melt-blown layer translates into depth loading, trapping dust particles that are very difficult to dislodge during the cleaning cycle.

The differences between the structure of commodity filters and filters using nanofiber technology translate into bottom-line savings over the life of the filter.

To understand the true value of an advanced-technology cartridge filter, users should consider all of the costs associated with the filter and its operation—purchase price, maintenance for filter changeouts, disposal costs, system energy use, and compressed-air expense.

Longer Filter Life = Fewer Filter Replacements

|

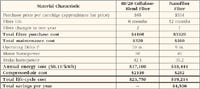

Comparison between the performance of 80/20 cellulose-blend and nanofiber filters. Results are based on a |

A lower initial purchase price may seem like a bargain, but the savings quickly evaporate when the life of the filter is factored in. Cellulose and blended-cellulose filters last about three to nine months before they must be replaced. However, cartridge filters with a nanofiber surface layer can operate at increased air-to-media ratios because of their lower operating pressure drop. In addition, they utilize less operating brake horsepower than cellulose and blended-cellulose products. These differences result in longer filter life. In fact, filters with nanofibers can perform at optimum efficiency for up to a year or longer in most applications.

A comparison of filter purchase cost alone over just one year, even before factoring in added maintenance and energy use, illustrates the true cost of traditional, lower-priced commodity filters.

|

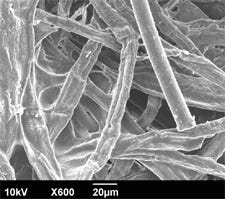

Blended-cellulose filter at 600× magnification |

Fewer Filter Replacements Means Reduced Maintenance Costs. Typical changeouts take two hours at a labor rate of $80/hr. When using hazardous dusts, additional disposal costs may be incurred. Because cellulose and blended-cellulose filters must be replaced more often than nanofiber filters, more maintenance time for changeouts is required. This is an important expense that increases the life-cycle cost of dust collection cartridge filters.

Lower Pressure Drop Means Energy Savings. The goal of a dust collection cartridge filter is to provide the highest possible filtering efficiency with the lowest possible pressure drop. To achieve high efficiencies, some manufacturers make the media pore sizes smaller, but this results in a higher pressure drop. Others add a melt-blown layer to a cellulose substrate. While the smaller pore sizes of the melt-blown layer increases efficiency, they add additional depth to the media, restricting airflow and increasing the pressure drop.

The thin nanofiber surface layer provides the highest possible filtering efficiency. In effect, the nanofiber layer does all the work, so the substrate can be highly permeable to provide a lower pressure drop. Because the pressure drop is low, the system may be able to use a smaller, less-expensive blower and require less energy.

Fewer Pulses Mean Less Compressed Air. Depth loading of dust, either within a melt-blown surface layer or in the media substrate, makes it much more difficult for a dust collector to pulse out the dust using a jet-pulse cleaning system. As dust builds within the filter’s substrate, static pressure increases, and the system must pulse more often to return to optimum static pressure.

|

A filter with a melt-blown surface layer shown at 600× magnification |

A straight cellulose filter with no surface treatment can pulse as much as 17 times more often than a filter with a nanofiber layer. Even a blended-cellulose filter with a melt-blown surface layer and an equivalent amount of media pulses more than eight times as often as a filter with a nanofiber layer. This phenomenon has a direct impact on a processor’s bottom line.

Compressed air is one of the most expensive utilities in a manufacturing plant. About 8 horsepower of electricity are used to generate 1 horsepower of compressed air. Over time, the additional use of compressed air from depth-loading filter media can result in substantially higher costs. If airflow is 20.4 scfm at six pulses per minute, the compressed-air cost of a system using a blended-cellulose filter would be approximately $2110, compared with a compressed air cost of $282 for a system using a nanofiber filter.

Total Savings. Taken together, the total cost of an inexpensive dust collection cartridge filter is significantly more than that of a premium filter that uses nanofiber technology.

Conclusion

When evaluating replacement cartridge filter options, users should remember that the cost of buying filters is not based on price alone. They should avoid the temptation to save a few dollars in the short run in order to save a few thousand dollars in the long run.

With more than 30 years of experience in dust collection technology, Ed Ravert is a senior application engineer at United Air Specialists Inc., Cincinnati. He can be reached at 800-252-4647, ext. 8789, or [email protected]. For more information, visit www.uasinc.com.

About the Author(s)

You May Also Like