Mechanical Conveying 96

April 5, 2007

Tubular Conveyors

Tubular Conveyors

Booth 1550 - Cablevey conveyors transfer products without the use of air. Cable/disk technology is used for a wide variety of products such as powders, chunks, flakes, pellets, prills, parts, shavings, crumbles, granules, fluff, regrind, and dust. The system layout is adaptable, with 3-D available. Convey rates up to 1240 cu ft/hr are possible. The units are dust tight, require low hp, and are extremely gentle on the product. They can be used for packaging lines.

Cablevey, Oskaloosa, IA 800-247-3344 www.cablevey.com

Dry Bulk Material Loading

Dry Bulk Material Loading

A material loading system loads dry bulk materials simply, efficiently, and quickly. The Floveyor aeromechanical conveyor machine transfers all types of granules, powders, flakes, and mixtures. It offers a unique transfer method that is compact, versatile, and reliable. The machine can be positioned at any incline angle. Customized machine lengths up to 90 ft are available. The low-horsepower unit is constructed of stainless or carbon steel. It contains dust and operates in a hygienic manner.

FloAero Inc., Encino, CA 818-789-0546 www.floaero.com

Material-Handling Systems

Material-Handling Systems

Company designs and manufactures material-handling systems that gently handle delicate value-added products through the production process with minimal loss, breakage, spillage, cleanup, and downtime. Systems include bucket elevators, vibratory feeders, belt conveyors, and hoppers.

Gough Econ Inc., Charlotte, NC 800-264-6844 www.goughecon.com

Roller Lacer

Roller Lacer

The Clipper Roller Lacer Gold Class is a portable tool that provides easy hook installation, reduces operator fatigue, and minimizes downtime without sacrificing precision. The unit handles wide belts in one simple operation; it can be driven by a cordless drill (18-V or higher) or operated manually with a handle or ratchet in emergency situations. The new Gold Class is approximately 12 in. longer than the standard roller lacer, allowing for extra stability when the lacer is placed up on sidewall pans for on-site installation. Available in widths of 24, 36, 48, and 60 in., the tool features a shelf that supports the belt and guides it into the hook points during installation. The belt shelf can be easily moved into a loading position for faster and easier insertion of the belt into hook points, and an improved belt clamp provides greater holding force for the belt.

Flexco, Downers Grove, IL 630-971-0150 www.flexco.com

Flexible Screw Conveyor

Flexible Screw Conveyor

Booth 1605 - Designed for conveying powders, granules, and blended materials, the Spiralfeeder is available in six sizes with a maximum conveying capacity of 600 cu ft/hr. Five flexible and rigid standard screw designs handle demanding conveying requirements. The conveyor is available as a stationary unit or as a portable system for multiple in-plant conveying uses. Multiple systems can be connected in-series to achieve the design flexibility of both lateral and angular changes in the direction of material flow to and from each process point. The conveyor includes a testing-based system-performance guarantee.

Automated Flexible Conveyor Inc., Clifton, NJ 800-694-7271 www.afcsolutions.com

AA Buckets

AA Buckets

Twelve sizes of new injection-molded AA buckets made of nylon complement the existing 22 sizes of ductile iron and cast aluminum buckets. The new products are engineered to match the original mill standard design. The full range of buckets conforms to the industry True Standard. Nylon buckets are ideal for use in foundry sand, coal, fertilizer, sand, gravel, and other abrasive applications. They provide consistent and precise discharge characteristics. The company also stocks 12 million elevator bolts in four styles and three materials.

Tapco Inc., St. Louis, MO 800-288-2726 www.tapcoinc.com

Split Sanitary Shaft Seals

Split Sanitary Shaft Seals

Booth 1731 - MECO split-shaft seals for screw conveyors are available in sanitary models that are easily removed and replaced for bench sanitizing. The patented seals contain dry powders in rotating food or pharmaceutical processing equipment, where seals come into contact with product. Designed for problem applications in which traditional packings fail to seal, the seals accommodate 6 mm and more of diametric shaft runout, radial misalignment, shock loads, and thermal shaft growth in high-temperature machinery. Simple to adjust and maintain, they can also protect shafts from abrasion damage and have a high mean-time-between-failures record.

Woodex Bearing Co., Georgetown, ME 800-526-8800 www.woodex-meco.com

Flexible Screw Weigh Batching System

Flexible Screw Weigh Batching System

Booth 1623 - This weigh batching system for mezzanines and other low-headroom areas utilizes low-profile flexible screw conveyors that are configured with motor drives at the inlet end of the conveyor, reducing height and width requirements at the discharge end. The automated system is composed of eight low-profile conveyors fed by roof-mounted storage vessels. Each group of four conveyors feeds either of two gain-in-weight hoppers that gravity discharge through the mezzanine floor to a ribbon blender on the plant floor. A system controller starts and stops each conveyor to weigh ingredients in sequence and then opens the slide gate valve to discharge the batch.

Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

Automatic Rope-Tensioning Device

Automatic Rope-Tensioning Device

Booth 2071 - This patented tensioning and monitoring device for aeromechanical conveyors reduces running costs and increases rope life by up to 40%. Aeromechanical conveyors operate by means of a continuous wire rope with accurately spaced polyurethane disks that move at high speed within a steel tube. At each end, the rope assembly runs around specially designed sprockets. The action of the rope traveling at high speed sets up an airstream that fluidizes and conveys product to the outlet, where the product is centrifugally ejected. High capacities can be achieved using low amounts of energy with minimal production degradation and separation.

Spiroflow Systems Inc., Charlotte, NC 704-291-9595 www.spiroflowsystems.com

Horizontal-Motion Conveyors

Horizontal-Motion Conveyors

Slipstick horizontal-motion conveyors are powered by a totally enclosed differential drive system that does not include maintenance-intensive springs, rollers, or belts. The conveyors move material along the pan in a horizontal, slow-forward, quick-return motion. This low-impact motion is gentle on the product and the conveyor, resulting in lower maintenance costs and longer operating life. The drive system is airtight, and the Slipstick can be supplied with a leakproof pan cover that contributes to a clean, dust-free facility. The units can be hung from the ceiling to save floor space. They operate at multiple speeds and in reverse. In addition, they can incorporate a wide range of gates and chutes.

Triple/S Dynamics, Dallas, TX 800-527-2116 www.sssdynamics.com

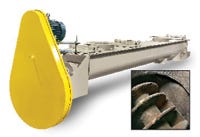

Screw Conveyors

Screw Conveyors

Company designs and manufacturers screw conveyors for extremely abrasive products such as glass cullet, fly ash, petroleum coke, and alumina. Construction features include a chromium carbide–clad plate for the screw flights and troughs and complete weld-on overlay of screw pipe. Other features include dust-tight construction, a high-torque drive unit, and adjustable packing gland seals for the shafts. Shafts are hardened in the seal area to prevent wear and reduction of shaft diameter. Easy-opening inspection hatches can be added as an

option.

KWS Manufacturing Company Ltd., Burleson, TX 800-543-6558 www.kwsmfg.com

Vertical Conveyors

Vertical Conveyors

Company offers conveyors for powder and bulk material before packaging. It also provides conveyors for packaged materials and pallet loads after the packaging process. All units are equipped with a rubber chain that is virtually maintenance free, quiet, lubrication free, clean, and stretch free. Continuous bucket elevators convey powder and bulk material horizontally-vertically-horizontally from one or multiple feed openings to one discharge. The continuously interconnected, spill-free buckets discharge at the end of the conveyor at one location. Pendulum bucket elevators convey powder and bulk material horizontally-vertically-horizontally from one or multiple feed openings to one or multiple discharges. The buckets are unconnected pendulum-mounted units that can be discharged as required at individual discharge locations.

Nerak Systems LP, Cross River, NY 914-763-8259 www.nerak-systems.com

You May Also Like