Additive Manufacturing Powder Handling: Time to Get Serious

February 20, 2020

As the growth of Additive Manufacturing (AM), or 3D Printing as it is commonly known, continues unabated, the techniques are being refined, the metallurgy of built components better understood, and productivity rates are accelerating. As a direct consequence, the need for the efficient and contained handling and processing of the metal powders that form the basis of the process has become increasingly critical. In short, unless the powders can be handled in volume and in a safe, contained way, the process will be limited to the highly specialized applications in aerospace and tooling.

In many of the current applications, two or three AM machines are typically in a room with the majority being fed with metal powder via small-volume containers. This may be acceptable when the number of AM machines is low and the build times take days. Yet, as AM machines inevitably increase in the production environment, and both the rates of manufacture and the size of printed components increase in turn, the effective supply of dense metal powders is an essential, rather than simply desirable requirement, if the technique is to reach its full productive potential. However, this effective transfer of metal powder must overcome two major factors: explosion risk and efficient transfer of dense metal powders.

The transfer of powders has long been a well-served area of engineering. From the days of an Archimedes spiral to today’s advanced vacuum transfer systems, in food, chemical, and pharmaceutical industries the movement of powder within production environments is common. Nevertheless, while traditional machine shops are familiar with the requirements of bar stock and sheet metal, or even the use of casting techniques, few of them have experience in the safe and contained transfer of powders without the risk of explosion, let alone those with bulk densities as high as 650 lb/cu ft in a contained manner.

Here are the process requirements and challenges associated with AM:

* Loading material to the printer from initial supply

o Bulk IBC

o Small containers

* Unloading surplus but unused powder from the build box and or the overflow collection and screening the product to remove agglomerates

o Direct from the printer

o From the overflow collection on the printer

o From so-called unloading stations

* Returning material to the printer for use in the next build

o After screening and collection

o After blending with a percentage of virgin material

o After drying, should the process be required, as may be the case in binder jet applications

* Achieving any of the above in either inert or non-inert conditions.

Avoiding Explosion When Processing Metal Powders

One of the obvious challenges is to keep the area of the workplace clean, and to avoid the risk of operators inhaling fine metal powders, while avoiding the need for cumbersome protective clothing and breathing apparatus. How many of us would enjoy our work if it involves full PPE day in and day out? Certainly, subtractive manufacture does not require this. For this reason, contained vacuum transfer immediately affords the advantage when compared to mechanical or positive pressure, or so called “blower system” pneumatic conveying in that in the unlikely event of a leak, air leaks inward keeping the powder contained.

Contained vacuum conveying is a simple concept. It essentially consists of a vacuum pump, a filter system, and a means of controlling the volume of powder within the generated airstream at a given velocity. The vacuum pump itself provides a means where the pressure in a system is reduced at the discharge end, and in so doing, causes air (or gas) to pass from the higher pressure to the lower pressure. For a given velocity, known typically as the saltation velocity, the airstream is capable of carrying a given amount of powder with it, thus transferring the powder from one end to the other. Upon arrival at the destination, a means of separating the powder from the airstream is needed, and hence a filter system is included to accomplish this.

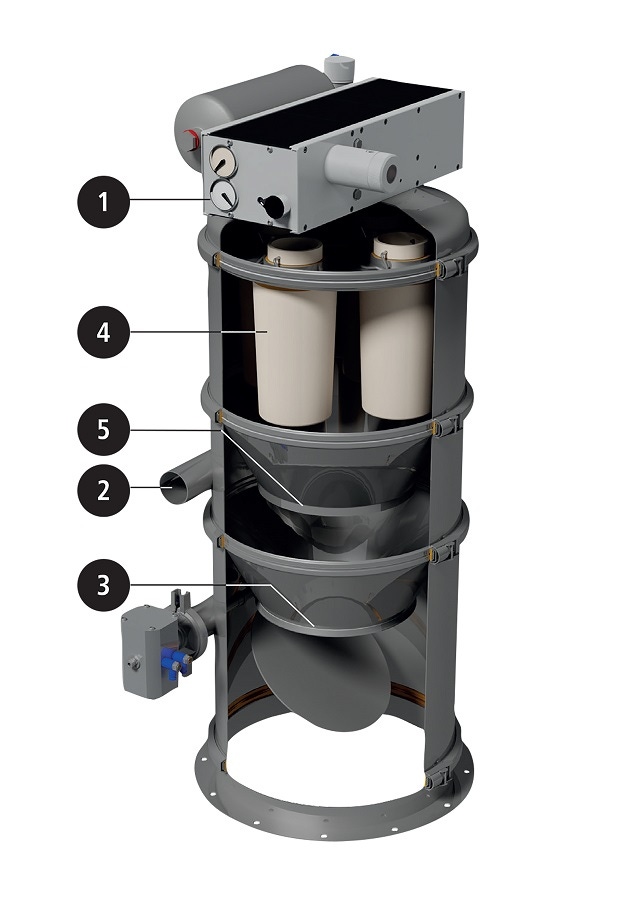

See Figure 1

Vacuum pump (1) produces negative pressure in the separating container of the vacuum conveyor. Air is sucked through the intake opening (2) having been transferred from a product feeding station and material for transportation is moved. The vacuumed air passes through the filter system (3) inside the separating container depositing material and it accumulates there. In the case of fine dust, an additional cyclone insert [used in the separator (4)] allows for higher flow rates due to lower filter surface load. After the separator container is filled, the vacuum pump is switched off. The pressure in the separating container quickly reduces to atmospheric pressure. The valve in the discharge module (5) opens and the transferred material falls from the vacuum conveyor directly into the receiving vessel. When emptying, the filter is cleaned by a back-flow pulse of compressed air. In this case, any filter cake is reliably removed. In the case of heavily ‘bridging’ or adhesive material, one can add optional piston vibrators and fluidizing units to aid discharge. After emptying is complete, the discharge valve closes and the conveying process begins again.

This all sounds simple enough, but as many readers will appreciate, unlike liquids, powders are far from predictable and behave in different ways depending upon such factors as moisture content, particle shape, particle size distribution, bulk density, and flowability, all of which combine to increase the challenge. To further complicate the situation, metal powders and indeed many powders that we might consider to be handled every day, can also be hazardous from a potential explosion perspective. Fine sugar, coffee creamer, and potato starch are examples of products known to have exploded when presented with the three conditions shown in figure 2.

See Figure 2a and 2b

Eliminating any one of the three factors shown in the “fire or combustion triangle” will prevent any risk of explosion. Generally speaking, particles greater than 500 microns are not considered to have a high risk. However, with metal powders typically in the D50 area of 30 to 45 microns, we cannot eliminate that sector.

Under the ATEX certification system for explosion protection, 13 ignition sources are identified as follows:

1. Chemical reaction

2. Hot surfaces

3. Mechanical sparks

4. Flames, hot gases

5. Electric units

6. Flash of lightning

7. Electric compensation currents

8. Ultrasonic

9. High frequency radiation

10. Electromagnetic waves

11. Adiabatic compression

12. Ionizing radiation

13. Electrostatic charges

Of the 13 factors listed, only the last is of concern in an all-pneumatic vacuum conveyor system supplying or unloading metal powder from the AM machine. By ensuring that all components are grounded and that each part of the conveying circuit is static dissipating, the last factor can be eliminated (Note: the commonly referred to condensate filtration and control is not part of the metal powder handling covered in this article and remains the responsibility of the AM machine manufacturer).

Critically, the ATEX Certification for explosion-free operation is only achieved after a rigorous process of detail design submission, testing and documentation, culminating in the award of a standard. The award is underwritten by the testing agency and results in the ability to use the Ex symbol with the statement of the areas and conditions for which it is approved. Here is an example:

ATEX certified for assembly in zones 1, 2, 21, and 22. EC type approval certificate number TÜV 02 ATEX 7005 X. Special conditions apply for the safe use of the equipment. II 1 D c 80°C/ll 2 D c 100°C - /II 2 GD c 100°C (T4)

The European standard of ATEX testing far exceeds the approach taken by the US NFPA as can be seen in the NFPA 484 standard for combustible metals which states: “NFPA codes, standards, recommended practices, and guides (“NFPA Standards”), of which the document contained herein is one, are developed through a consensus standards development process approved by the American National Standards Institute. This process brings together volunteers representing varied viewpoints and interests to achieve consensus on fire and other safety issues. While the NFPA administers the process and establishes rules to promote fairness in the development of consensus, it does not independently test, evaluate, or verify the accuracy of any information or the soundness of any judgments contained in NFPA Standards.”

Addressing Concerns About Oxygen in Explosions

Currently there is some confusion in the marketplace concerning the need to address another of the elements of the fire triangle: the presence of oxygen. There is no question that eliminating oxygen is one way of avoiding an explosion risk. However, it is not essential for any powder with a Minimum Ignition Energy (MIE) level great than 1mJ as we have shown from the previous ATEX certification statement.

Some user risk analysis studies have resulted in companies forming the opinion that reducing the oxygen level to below 6% is desirable, and while doing so definitely applies a belt and braces approach to safety, it is not needed as long as the ATEX certification exists and the safeguards are followed.

There is a second requirement when conveying under inert conditions; namely, avoiding oxidation of the metal powder. This is an area for metallurgists to consider, but in either case, if inert transfer is needed, it is essential to use suppliers who have experience with such systems. Inert gas, typically nitrogen or argon, is expensive. In order to minimize the gas, the use of “so called” closed-loop systems have been employed. In these systems, the exhaust from the vacuum pump recirculates to become the conveying gas once more. Such systems require oxygen monitoring, the ability to purge the system and verify the O2 level, as well as controlling that level during the material transfer. An additional consideration, such as the increase in temperature and pressure that can occur during the recirculation until a steady state is reached, also needs to be addressed. Often this requires interface with the AM machine controls where permissive signals are needed to allow the process to take place.

Figure 4 below shows a basic closed-loop circuit for an unloading and screening station. Note that the container receiving the powder is inert and requires connection in such a way that the inert conditions are maintained when disconnected from the screener.

See Figure 4

Efficient Metal Powder Handling

As outlined in the opening section of this article, the AM process requires several operations to ensure powder handling is efficient. It is also likely that additive manufacturers will have banks of machines using the same metal powder as the technique develops, as well as having some that are changing from material to material as the need demands. In the former case a conveying system that can both supply and unload three or four machines with powder, as shown in the graphic below, and in a contained, operator-friendly manner by using the same circuit, would be highly desirable.

See Figure 5

In the case where one machine needs to be used with multiple, different powders, ease of cleaning between powder changes becomes the issue. How quickly can one change materials without the risk of cross contamination? No tools disassembly and quick-change filter systems are just two solutions to satisfy the obvious requirements.

Ever-increasing production requirements also demand a more efficient supply of raw material. Currently we see many of the metal powders being delivered in small volume hoppers or tubs. The simplest reason for this is the weight of the powder. Five liters of most material is a small volume, typically filling containers somewhat similar to the types of tubs in which protein powders are supplied. One the other hand, five liters of a dense nickel chrome alloy can weigh as much as 100 lb. As a result, manufacturers of these dense powders have taken to supplying multiple tubs on a pallet that require a fork lift to take them to the production machine. Worse still, they take a lot of shelf space in a warehouse or pre-use storage area.

Taking the Pharmaceutical Industry Approach

Suppliers of metal powders are now beginning to offer these powders in larger bulk quantities, delivering them within a hopper commonly known as an intermediate bulk container (IBC). For the heavier metals, 130 l is common. This solves the problem associated with the small containers, but requires a simple method of docking, dosing and possibly weighing the material as it is transferred to the printer using vacuum conveyors.

See Figure 6

Powder handling equipment suppliers are now developing systems that will make increases in the production rate of additive manufactured components a practicality. Whether it is loading the printers, unloading them, screening the metal powder or returning previously used powders to the production process, it is clear that the handling and containment of powders in the production environment must develop if the technique is to become viable for the much larger general manufacturing market. Such systems must be capable of conveying dense, heavy metal powders in a contained, safe, and practical manner.

Nick Hayes is president, Volkmann Inc. Volkmann engineers and manufactures high-quality, high-performance vacuum conveyors, systems for additive manufacture, bag dump stations, unloaders, and equipment for the contained, gentle, and damage-free transport of metal powders, fine chemicals, granules, pellets, tablets, food particles, and small components for the pharmaceutical, nutraceutical, food, chemical, and additive manufacture industries. For more information, call 609-265-0101 or visit www.volkmannusa.com.

You May Also Like