Solex Unveils Standalone Discharge Feeders

Expertise in mass flow of bulk solids leads to new lineup

July 21, 2021

Solex Thermal Science is expanding its presence in the bulk solids market with a new lineup of discharge feeders for the bulk material handling market.

The Canadian-based bulk solids thermal exchange technology provider for more than 30 years has announces the initial rollout of three uniquely designed and in-house fabricated discharge feeders for different applications such as sand, sugar, seeds, minerals, and fertilizers.

“Reliable, uninterrupted mass flow of bulk solids plays an important role in material handling systems efficiency while maintaining product quality,” said Solex Thermal Science CEO Lowy Gunnewiek. “Through our expertise in designing and fabricating moving bed heat exchangers, Solex Thermal Science has decades of experience in designing discharge devices that have been proven to achieve desired flow behaviors. Our world-tested equipment can be tailored to different material flow properties, while providing operators with maximum control and a guaranteed first-in-first-out flow sequence.”

Solex’s discharge feeder lineup includes:

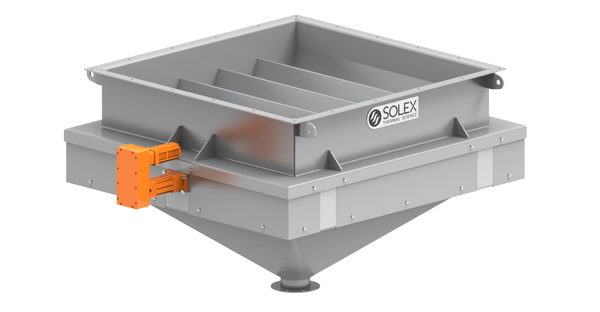

• Vibrating louvers: Best suited for lighter material applications such as sand, sugar, or plastics. Solex’s vibratory discharge feeder uses a series of partially overlapping louvers carefully positioned within a self-supported frame that vibrates linearly to offer a full live-bottom system. The system is designed to ensure mass flow by allowing product to flow along the multiple overlapping shallow louvers into a series of slot openings.

• Sliding frame: Best suited for medium-duty applications such as seeds, beans, or delicate granules. The feeder is comprised of a fixed part made up of a series of small mass flow hoppers that feed the material toward the sliding frame. As the sliding frame moves horizontally back and forth, the solids are subsequently discharged from the mass flow hoppers.

• Oscillating gate: Best suited for heavy-duty applications such as minerals, fertilizer, and other high-density granular solids. In Solex’s oscillating gate, the product splits into the two symmetrical mass flow funnels, created by the fixed outer walls and the moving inner walls at the center that form a pair of slotted shaped openings that the material flows through.

“With all our discharge feeders, our scientific design approach combined with practical engineering, we carefully account for the transition between the silo or bin to the discharge, a critical aspect in achieving the desired flow characteristics,” said Solex Thermal Science global sales director Pedro Moran. “In addition, we consider the spatial constraints and equipment used to convey the bulk solids after passing through the unit. In all cases, our experienced staff work to ensure the right feeder is customized correctly for full-scale implementation.”

Solex Thermal Science, Calgary, AB, Canada 403-254-3500 www.solexthermal.com

About the Author(s)

You May Also Like