Predicting Feeder Performance from Powder Flow Measurements

July 8, 2015

By Tim Freeman and Doug Millington-Smith, Freeman Technology, Ralf Weinekötter, Gericke AG

Predicting the performance of processing equipment from measurements of powder properties is an important goal for the powder processing industries. This article describes new collaborative research from Freeman Technology and Gericke to establish predictive correlations for the volumetric flow rate delivered by screw feeders, using dynamic powder testing that can be used to accelerate and optimize screw feeder selection.

In the powder handling industries screw feeders are used routinely to control the flow of material from a hopper into a process. The properties of the powder have a direct impact on the performance of the feeder, making it essential to tailor the design of any given system to the product being handled. A poorly matched powder/feeder combination will typically be associated with low feed rates, high screw torques, and the accumulation of powder on the tube walls. All these factors decrease both short and long term operating efficiency.

This article describes a collaborative study carried out by Freeman Technology (Tewkesbury, UK) and Gericke (Zurich, Switzerland) to identify powder properties that can be reliably measured to predict feeder performance. The work highlights the value of dynamic powder characterization within this context, and concludes with the development of robust models that enable the prediction of feed rate through a screw feeder from flow properties such as Specific Energy (SE), Flow Rate Index (FRI), and Aerated Energy (AE). These models make it easier to select a feeder for a specific powder and predict its likely performance with a high degree of confidence.

Specifying Screw Feeders

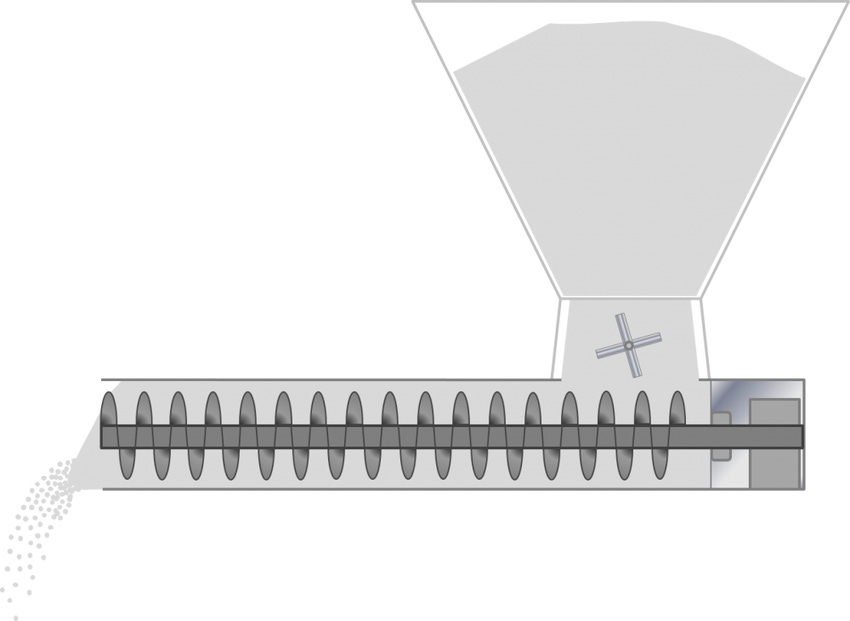

Screw feeders consist of one or more rotating augers or helixes mounted in an enclosed chamber (see figure 1). As the auger rotates, powder is transferred according to the Archimedes screw principle, which has been exploited for material transport for centuries.

Screw feeders are used across many industries and Gericke has been supplying machines for handling chemicals, foods, construction minerals, plastics, and detergents for decades. The three factors that directly influence the choice and specification of each feeder are:

• Installation constraints associated with the plant layout – the number of feeders, available headroom, feed distances, and mounting requirements.

• Process requirements – feed capacity, whether the plant is operating continuously or in batch mode, operating pressure, the accuracy needed, and the extent of automation.

• Material properties – is the material being handled free-flowing, cohesive, or adhesive, fragile and prone to attrition, abrasive, compressible, or fluidizable.

Key design variables that can be manipulated to meet any combination of requirements include: the size of the feeder (diameter and length); the geometry, drive and pitch of the auger; and the accessories used to ensure consistent flow. Vibrational feeders and fluidization or agitation in the feed hopper are all possible options. Feed rate may be controlled on the basis of weight (gravimetric) or volume (volumetric).

For Gericke, specifying the optimal screw feeder for any given application is critical to operational success. A feeder that is poorly matched to the product it is handling is likely to be associated with poor long term operation, which can manifest in a number of ways. Flow rate may be erratic or poorly controlled, for instance, directly impacting the overall performance and efficiency of the process. If the powder is cohesive, on the other hand, the accumulation of material within the equipment may be problematic, especially if there is frequent product changeover and/or sensitivity to batch-to-batch contamination.

Understanding how to characterize powders so as to be able to predict their performance in different types of equipment is, therefore, extremely helpful. Within the screw feeder, powders are subjected to different environments, flowing gravitationally from the feed hopper into the forcing, potentially compacting flow regime within the rotating auger(s) that drives material forward. The way in which a powder responds to these conditions depends directly on its properties. Powder properties consequently have a major impact on equipment choice and the need or otherwise for bespoke development.

In the study, experiments were carried out to assess whether properties measured using the FT4 Powder Rheometer could be correlated directly with feeder performance. The underlying aim was to assess the feasibility of predicting feeder performance from powder properties to accelerate the identification of an optimal screw feeder solution for any given material.

Correlating Powder Properties with Screw Feeder Performance

An experimental study was carried out to investigate correlations between the properties of five different powders and their performance in two different screw feeders. The five powders tested were:

• Calcium hydroxide

• Maltodextrin

• Milk protein

• Cellulose

• Calcium citrate

In the first stage of the study, samples of each powder were subjected to comprehensive testing using an FT4 Powder Rheometer[1]. Dynamic, bulk, and shear properties were measured for each powder with a high degree of repeatability (RSD<5%) in each case. Samples of each powder were then run through each of two Gericke screw feeders to determine the volumetric flow rate (l/hr) delivered at an auger rotation speed equivalent to 80 Hz. Volumetric flow rate (in l/hr) was calculated from measurements of mass flow rate (in kg/hr) and poured density.

The two screw feeders used were a DIWE-GLD-87 VR, full flight single-screw feeder using tube No. 3 and a DIWE-GZD flat bottom double-screw feeder using a 12x13.5-mm tube with a conical core. The GLD machine is a compact, versatile feeder used for high-accuracy feeding of most dry solids, for pilot scale applications, and for those requiring frequent material changeover. The GZD unit is a compact, self-cleaning twin screw extruder used for low-capacity applications, and is particularly suitable for feeding materials with poor flow characteristics.

Table 1 shows the data set measured for all five powders, including the average volumetric feed rate in L/hr. A multiple linear regression was performed to reveal correlations between these two sets of data. This is a mathematical process that produces an equation quantifying a dependent (y) parameter - in this case volumetric flow rate - in terms of influential independent (x) variables - in this case the powder properties. The process generates a p value for each parameter, which indicates the probability that the parameter’s contribution to the relationship is statistically insignificant. The higher the p value, the more likely that the parameter has no bearing on the relationship, and therefore a smaller p value is associated with a parameter that is more relevant. For the purposes of this study a p value of 0.1 was taken as the upper limit for relevance and parameters with p values higher than this were eliminated to derive a robust relationship.

For the GLD feeder this multiple linear regression step produced the following relationship:

Feed Rate = 49.54 FRI – 13.81 SE + 163.8

(R2 = 0.9466)

The term R2 is a measure of the ‘goodness of fit’ between the model and the data with higher values closer to the upper limit of 1, indicating a close fit. This relationship suggests that, of all the powder properties measured, only two dynamic properties are needed to robustly predict feeder performance – Specific Energy (SE) and Flow Rate Index (FRI). The parameter SE reflects how a powder behaves when in an unconfined state. FRI, on the other hand, describes how the powder’s resistance to flow changes as a function of flow rate, and is simulated by increasing or decreasing the tip speed of the helical blade of the powder tester.

During FRI testing, flow energy is measured at a blade tip speed of 100 mm/s (as for BFE testing), then at 70, 40, and 10 mm/s. The value of FRI is the ratio of the flow energy measured at 10 mm/s to that measured at 100 mm/s. An FRI that is greater than 1 indicates that the resistance to flow is greater, as evidenced by a higher flow energy, when the powder is made to flow more slowly. All the powders measured in this study have an FRI above 1, therefore all exhibiting this shear thinning behavior.

Figure 2 shows the measured flow rates for the five powders along with the values predicted by the derived model. As suggested by the R2 value for the correlation, the predicted values very accurately describe the observed performance of the powders in the GLD feeder.

To challenge the predictive ability of the derived relationship, two additional powders were tested - cement and lactose. Figure 3 shows the measured flow rates for each of the original five powders, and the two new materials (red), along with the values predicted from their powder properties. A revised R2 confirms close agreement between the predicted and measured flow rates for the data sets incorporating all seven materials, and the feasibility of predicting volumetric flow rate from powder property data.

The exact same process was repeated to derive a correlation that could be used to predict performance in the GZD feeder. Here a simpler correlation was observed with Aerated Energy (AE) the only parameter found to be highly relevant.

Feed Rate = -0.1114 AE40 + 34.82

(R2 = 0.8383)

AE is the flow energy of the material measured when the sample is aerated by air flowing up through it at a defined linear velocity - in this case 40 mm/s, hence AE40. Cohesive powders tend to have a relatively high AE, since aeration does little to reduce the resistance they present to flow, while for free-flowing powders AE can approach 0 as the powders fluidize. The materials tested here exhibit a relatively broad range of AE values, but a robust relationship between AE and volumetric flow rate holds for all materials.

Figure 4 shows the measured flow rates for the five powders along with the values predicted by the derived model. As suggested by the R2 value for the correlation, the predicted values once again accurately describe the true performance of the powders in the GZD feeder.

As with the other feeder, the study was extended to verify the ability of the relationship to predict the volumetric flow rate achieved with cement and lactose. As before, the correlation performed robustly in this predictive mode.

Predicting Performance

The results from this experimental study demonstrate the feasibility of developing robust correlations between measurable powder properties and the volumetric flow rate delivered by different designs of screw feeder. Each screw feeder imposes different process conditions on the powder and this is reflected in the specific attributes of the powder and the parameters that are found to be relevant for predicting feeder performance. However, in both cases it is dynamic powder properties, rather than shear or bulk properties, that were found to be of most relevance.

The approach taken in this study can be more broadly applied to determine correlations for predicting the performance of a wide range of powder processing equipment. Multi-faceted powder characterization provides an essential foundation for such work, supporting the identification of those properties that are most relevant to the performance of a powder in any specific unit operation. Powder testers that enable this approach can therefore be extremely valuable for optimizing a range of powder processes.

Introducing Dynamic Powder Testing

The FT4 Powder Rheometer enables the measurement of bulk, shear and, uniquely, dynamic powder properties. As a result, it allows a powerful, multi-faceted approach to powder testing that has proven extremely valuable for identifying powder properties that correlate robustly with aspects of process performance. Such studies often highlight the greater relevance of dynamic properties relative to shear and bulk property measurements.

Dynamic powder testing was developed as a direct response to the need to measure powder flowability under conditions that closely represent the process environment. Dynamic powder properties are determined from measurements of the torque and force acting on a helical blade as it rotates through a powder sample along a defined path (see figure). It therefore has an easily comprehensible measurement principle that can be intuitively related to flow behavior in many process steps, such as screw feeding.

Basic Flowability Energy (BFE), a primary dynamic property, is measured on a downward traverse of the blade which forces the powder against the base of the test vessel. It reflects how a powder will flow under forcing conditions in a confined state. Specific Energy (SE), in contrast, is measured as the blade travels upwards imposing a gentle lifting, slicing action on the powder. This parameter more closely reflects behavior in a low stress, unconfined environment. A range of other dynamic properties can be measured by extending these basic protocols to directly investigate the performance of a powder in a process-relevant way.

Dynamic test methodologies are well-defined, largely automated, and incorporate a sample conditioning step to ensure that powders are tested in a reproducible state. In combination with precisely engineered instrumentation these features deliver high repeatability and reproducibility. Dynamic testing is often able to differentiate powders that other test methods suggest are identical, that go on to process differently. This performance, in combination with the unique capability to measure powders in a consolidated, conditioned, aerated or even fluidized state, makes dynamic testing a powerful technique for process related studies and equipment selection.

Tim Freeman is managing director, Freeman Technology; Doug Millington-Smith is applications specialist, Freeman Technology; Ralf Weinekötter is managing director, Gericke AG.

References

1. Freeman R. “Measuring the flow properties of consolidated, conditioned and aerated powders — A comparative study using a powder rheometer and a rotational shear cell”, Powder Technology 174 (2007) 25–33.

You May Also Like