Feeder Selection: Factors to Consider

Continuous feeding systems are used in processes where precise material addition is required throughout the manufacturing operation. The primary objective of continuous weighing is to automatically measure and control the rate of flow of bulk material in units of weight per unit time.

June 9, 2020

Tom Picone, director of business development, Vibra Screw Inc.

Continuous feeding systems are used in processes where precise material addition is required throughout the manufacturing operation. The primary objective of continuous weighing is to automatically measure and control the rate of flow of bulk material in units of weight per unit time. There are a number of continuous weighing devices for dry bulk solids: loss-in-weight feeders, weigh belt feeders, pivoted weigh screws, and mass flow meters. For this article, we are going to limit the discussion to the differences between a loss-in-weight feeder and a weigh belt feeder and when to choose one over another.

What is a Loss-in-Weight Feeder?

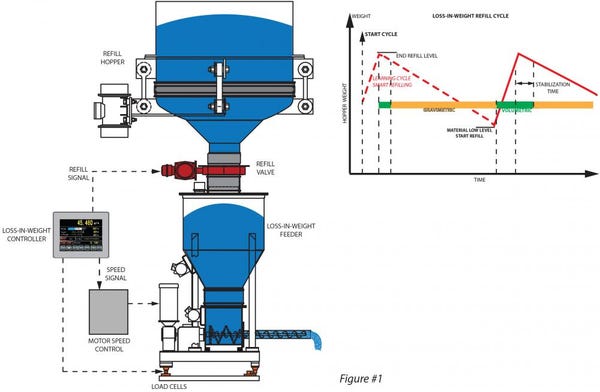

A loss-in-weight feeder is a continuous gravimetric feeder that senses the loss (or absence) of material being fed. By continually weighing the entire feeder, hopper, and material, the rate of the system’s weight loss is precisely controlled to match the desired feed rate.

A loss-in-weight feeding system includes a supply hopper, a metering feeder, a supporting scale system with microprocessor controller, and some type of refill mechanism. The system either electronically or mechanically balances tare weight of the hopper and feeder so the load cell and controller senses only the weight of the material in the supply hopper.

At time zero, the hopper is full (high weight), and the operator enters the set point or desired feed rate into the controller. As time and discharge advance, the actual sensed “loss-in-weight” follows the decreasing scheduled weight ramp in the controller whose slope is a direct representation of the desired weight of delivered material per unit of time (set point). The controller makes frequent comparisons of sensed vs. desired rate and alters the feeder’s output, keeping it at the set point.

Once the sensed weight reaches the hopper refill level (low weight), the controller locks the feed system into volumetric control. The hopper is recharged, and the loss-in-weight cycle repeats. Loss-in-weight feeders can use several different types of feeding apparatuses to control the metering of the material: screw feeders (single or twin), electromagnetic vibratory feeders (pan or tube), and if the application warrants, a rotary feeder.

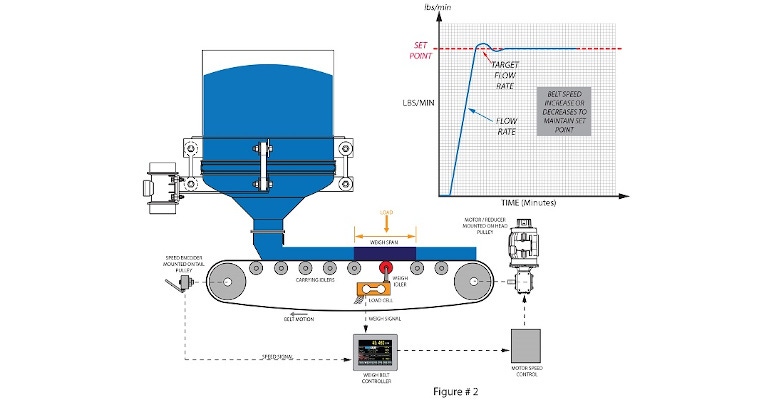

What is a Weigh Belt Feeder?

It can be any number of material control devices that use a relatively short conveyor belt over which material passes and is at some point weighed through the belt. The weigh belt feeder uses a load cell that measures the weight of a fixed-length section of belt, yielding a figure of material weight per linear distance (feet) on the belt. A speed sensor (encoder) measures the speed of the belt. The product of these two variables is the mass flow rate of solid material “through” the weigh feeder:

W = Fv/d

W = Mass flow rate (pounds per minute)

F = Force of gravity acting on the weighed belt section (pounds)

v = Belt speed (feet per minute)

d = Length of weighed belt section (feet)

The continuous weigh belt controller, a closed-loop device, senses both weight and belt speed when calculating actual feed rate. The controller compares the actual rate to the operator’s set rate and automatically adjusts belt speed as required.

Factors to Consider When Deciding on a Loss-in-Weight or Weigh Belt Feeder

Accuracy

Loss-in-Weight Feeder

The industry standard for loss-in-weight feeders accuracy has been, “Provides an accuracy of ±¼ to ±1% of set rate at ±2 sigma based on a minimum of 30 consecutive samples of one minute, 30 revolutions of the screw, or 1% of scale capacity, whichever is greater. Accuracy may vary depending on material flow characteristics”

There are critical areas of loss-in-weight feeder design that directly affect its ability to be accurate:

1. The volumetric feeder portion of the loss-in-weight feeder must be capable of producing 1-2% accuracy on its own in order for the loss-in-weight feeder as a system to produce 1/4% to 1/2% gravimetrically with most materials.

2. When the feeder goes through its refill cycle (to fill the feeder’s integral hopper) the control algorithm goes from a gravimetric mode to volumetric mode and back to gravimetric (as shown in the loss-in-weight diagram Figure 1). So, for the period of time loss-in-weight feeder is in a “volumetric” mode the feeder is not under true automatic control. Some loss-in-weight controllers use “learning” control algorithms that take the control data learned over time, memorizing screw speed before and during previous refills, and making changes based on that experience. Note, some loss-in-weight feeders lock in last known screw speed before the refill cycle which does not compensate for material handling characteristics of the material. This creates a higher degree of inaccuracy.

3. Ideally a loss-in-weight hopper should be large enough to provide at least 10 minutes of material retention time at maximum feed rate for conditioned, de-aerated material. This helps during hopper refill providing a buffer between conditioned material and aerated material. Fast refills of the loss-in-weight hopper shortens up the time when in the volumetric mode. Typical refill times should be in the 5-15-second range, depending on the size of the loss-in-weight hopper.

4. Use proper equipment to refill the loss-in-weight hopper. Never use aeration devices to fluidize material to get it out of the supply bin. Always use discharge devices that instantly discharge material when the refill valve opens.

5. When using a loss-in-weight with vibratory pan or tube, the head load from the supply hopper pressing down on the pan can change the vibration amplitude thereby changing rate output. This is seen when the material level in the hopper changes the pressure changes. A proper designed hopper needs to be used to prevent this change in head load.

Weigh Belt

The industry standard for weigh belt feeders has been, “Provides an accuracy of ±½% of totalized weight based on a minimum sample of one minute or two circuits of the belt, whichever is greater or ±¼% to ±1.0% of set rate at 2 sigma based on 30 consecutive one-minute samples. Accuracy may vary depending on material flow characteristics.”

Getting the best accuracy out of a weigh belt requires attention to a number of factors. This includes:

1. Obviously the weigh belt must be sized properly for the type of material being handled. The correct lb/ft loading for accurate weighing, correct belt speed for the material type.

2. If handling a powder especially a fine potential fluidizable powder, the storage bin above the feeder should have at least 10–15 minutes of retention time in the bin to assure constant bulk density.

3. Flow promoting devices are needed for those materials that have poor handling characteristics. Ideally the inlet nozzle that feeds the material directly to the belt surface should have a profile that helps reduce material head load off the belt at the inlet. This helps reduce horse power requirements and the potential for belt slippage during initial belt start-up.

� a. Large or long fibrous materials are the hardest materials to get to flow on a belt. Making the 90 degree turn from bin to belt surface requires proper design of feeder inlet chute. Special inlet metering tubes which have a special geometry are used in the wood and tobacco industry to assure proper material flow. The feed outlet should be at least 3X the size of the largest particle size to assure no material hang-ups.

4. Proper belt tension is critical for maintaining good accuracy. Over tensioning a belt (usually to prevent belt slippage or belt tracking) can greatly affect accuracy by applying downward belt tension on the weigh mechanism (scale).

5. Improper speed encoder location or improper pulses per revolution per the feed rate can create drastic effect on accuracy. Remember a weigh belt requires two accurate components for accuracy, accurate belt speed and accurate weighing of material on the belt. If either one is off, the weight belt will not get the desired accuracy.

Feed Rate

Loss-in-Weight Feeder

At which feed rate is a loss-in-weight feeder chosen over a weigh belt feeder. For loss-in-weight feeders, as the feed rate increases, the higher the cost of the system. There are several factors in choosing a loss-in-weight feeder: screw size, load cell capacity, and hopper size.

1. The sizing of the weigh hopper has significant effect on the feeder’s sensitivity to changes in weight. The larger the hopper, the longer time between refills, but the weigh scale becomes less and less sensitive to changes in weight as the hopper size increases. This is because the scale has to support the weight of the material in the hopper, as well as measure the loss of weight from the feeder. These two requirements often conflict with each other and tradeoffs must be made. The problem is compounded if the hopper and support structure weight is also supported by the scale.

2. When using a strain gauge load cell for loss-in-weight applications the load cell capacity is directly influenced by the required feed rate, weight of equipment, and live load capacity of the hopper. The load cell’s capacity is broken down into three components: tare--which is the weight if the mechanical equipment (feeder and hopper); live load--which is the material weight in the hopper; overload--which helps protect the load cell from being damaged from some external force like an operator standing on the scale. The load cell size provides a correct millivolt per weight (scale resolution) for the required feed rate and if the load cell becomes too large than the feed accuracy can suffer.

3. Loss-in-weight feeders can go as low as 15 lb/hr feed rate with a ½ cu ft hopper. These feeders are typically refilled by hand or volumetric feeder with positive material shut off gate.

4. As the required feed rate increases, the hopper capacity increases as well as the refill volume. The maximum feed rate of a loss-in-weight feeder where is starts to become impractical to use is at a 6-in. screw or around 600 cu ft/hr feed rate. A 6-in. loss-in-weight feeder handling a powder at 40 lb/cu ft requires a hopper of 200 cu ft minimum. Refill will be 100 cu ft every 10 minutes. Desirable refill time is between 10-15 seconds, which make the requirement for the refill device to be 24,000 cu ft/hr. The refill valve will need to be at least 36 in. in diameter. This drives up the system cost plus the additional head room to have a loss-in-weight feeder with a 200-cu-ft-capacity hopper plus another refill hopper of a minimum of 150 cu ft capacity. The system becomes quite tall and may not fit in the process space.

Weigh Belt Feeder

1. Weigh belt feeders can be used on a wide variation of materials, from fine powders (like TiO2) to large particle size material (like aggregate or wood chips).

2. The application of a weigh belt is based on the material to be handled, its bulk density, the required feed rate and particle size. As you will see later there are other factors that influence specific design criteria of a weigh belt feeder.

3. Weigh belts can be purchased in belt widths from 6 to 96 in. with feed rates from .025 to 3,000 STPH. Typical feed rate turndown is quoted as 20:1 with varying the belt speed, but 100:1 if both the belt speed and material bed depth are changed. If bed depth is changed the lb/ft loading on the belt should not exceed the minimum or maximum loading of the load cell.

4. Ideally for fine materials the bed depth and belt speed should be kept to a minimum as to not lose control and flood the belt with material. Belt speeds are generally in the 1 to 100 ft/min and material bed depth can be anywhere between 0.5 to 12”. Ideal belt speed range 10-60 ft/min preferred, 10-30 ft/min for abrasive materials, and for higher feed rates when handling non-floodable materials the belt speed can be as high as 100 ft/min with material bed depth up to 24 in. Note the distance from the feeder inlet to the weigh bridge should be no closer than 1.5 to 2 seconds for material settling time. This needs to be considered when calculating belt speed for the given application. For high rate applications that require higher belt speeds the belt length may need to be increased to move the weigh bridge further down the conveyor to provide the required settling time.

5. The only requirements on the storage silo above the weigh belt is that when handling a fine powder there must be 10-15 minutes of material retention time in the bin above the feeder to make sure the material is de-aerated to a constant bulk density. The other requirement is that the material flow out of the storage bin must have consistent and uninterrupted flow of material. If it does not the bin should be equipped with a flow promoting device.

6. If the material is heavy with a large particle size, there should be a gate valve between the bin outlet and weigh belt inlet. This is particularly true for mass flow slot style outlets where a pin or slide gate should be used to prevent belt damage during initial filling of the bin. In some cases if it is a large opening impact idlers (supporting the belt) under the inlet should be used.

Design and Environmental Considerations

Loss-in-Weight Feeder

1. Loss-in-weight feeders with screw or vibratory feeders are limited to the length of the volumetric feeder screw, tubes, or pans for conveying distances. Screws and tubes can be extended but within reason and not so long that they can affect the scale or load cells.

2. Loss-in-weight feeders should not be installed outdoors, especially the large units without adequate environmental protection. Their accuracy can be directly affected by wind currents. Loss-in-weight feeders are weighed structures designed to detect small changes in weight on the load cell(s). It does not take much wind to affect the feeder’s performance.

3. Extreme changes in air temperature around the loss-in-weight feeder does not generally affect the feeder’s performance, unless the temperature exceeds the rated temperature range of the load cell(s) or other components.

4. Temperature of the material being handled does not affect the feeder as long as the temperature does not exceed the limits of the feeder components like bearings and seals. Potential heat transfer into motor and reducer should be considered and adjusted for.

5. Loss-in-weight feeders always require flexible connections between the refill equipment and the equipment the material is feeding into.

6. Loss-in-weight feeders can handle mildly abrasive materials with hardened or coated surfaces designed for this type of material.

7. Dust collection on loss-in-weight feeders that are being automatically refilled by pneumatic gate valve should have some form of dust collection, especially with an integral bin as part of the loss-in-weight over 10 cu ft. Vent filter socks attached to the hopper cover work reasonable well on small bins, but if the material is very fine and cohesive the filter sock will blind over. Larger bins where there is a large volume of material filling the bin in a short period of time will displace a lot of dust-laden air. If the air is not properly vented the feeder will be pressurized and potentially vent out through the feed screw or vibratory feeder disrupting the flow of material. Large bin loss-in-weight feeders should be connected to a dust collection system and the vacuum should only be running during refill. Pulling a vacuum on the feeder at any other time of the feeding cycle can cause accuracy errors.

8. When feeding into any device or system that may have positive pressure, such as a positive pressure conveying system, the loss-in-weight feeder must be isolated from the pressure. Loss-in-weight feeders are designed to measure small changes in weight. Pressure at the loss-in-weight feeder discharge will be seen as weight change and the feeder does not know if it is the actual material feeding that is causing the weight change or the pressure change. The feeder instrument will try and compensate for the change and accuracy of feed will be affected.

9. Loss-in-weight feeders are used extensively in sanitary applications. They can meet most any food or pharmaceutical requirement for quick disassembly and wash-down.

Weigh Belt Feeders

1. Weigh belts convey distance can easily be altered to meet most applications. The normal width to length (pulley to pulley) ratio is about 2.5 to 3:1 length to width as a minimum for proper belt tracking. Weigh belts can be lengthened to as long as 60 ft and inclined up to 20 degrees.

2. Weigh belt feeders can be installed outdoors without being affected by the weather as long as they are the enclosed type and preferably with an enclosed bottom using a drag or screw cleanout.

3. Like loss-in-weight feeders the change in air temperature does not generally affect the feeder performance as long as it does not exceed the load cell and speed encoder temperature specification for performance. In extremely cold environments, the belt may become stiff and less pliable, which can affect the weighing ability. This normally does not happen as long as the belt is moving. For long shutdown in cold weather, the belt should be run to limber the belt and prevent stiffness prior to running material.

4. High material temperature can affect the feeder performance if care is not taken to use a belt that is rated for the material temperature. Most belt manufactures can provide high-temperature belts. The problem is finding a belt that can handle the high temperature and be flexible enough to not interfere with the weighing of the material. Also, belt conveyor high-temperature ratings are designed for applications where the belt is not in an enclosure and running at high speeds. When running at low belt speeds and enclosed, the material has less time to shed some of its heat so the material actually bakes the belt, which can break down the belt and have premature failure.

5. Weigh belts can be rigidly connected to upstream and downstream equipment without the need for flexible connections unless the silo or bin is on load cells or there is a vibrating bin discharger in use.

6. Weigh belts have been used for decades handling abrasive material. Most belt manufacturers make abrasion-resistant belts. However, like high-temp belts, they are usually heavier and stiffer, which affects feeder performance. Note that belts typically abrade due to material head load at the infeed to the belt. A good solution to prevent abrasion is to use a pre-feeder like a vibratory conveyor metering the material on the belt surface.

7. Like loss-in-weight feeders, weigh belts have been used extensively in sanitary applications. Most sanitary-style weigh belts come with cantilevered belts for easy removal for wash down. All bearing, motor, and reducers are now produced in stainless or sanitary designs. The speed encoders are also made for wash down applications. The only issue is with the load cells, which—although stainless—should not be cleaned with high-pressure washers.

8. The gravimetric weigh belt’s biggest deficiency is vulnerability to mechanical problems is due to dust, moisture, or fumes from downstream process. Dust or material can spill off the belt at the inlet, especially at initial fill of the supply hopper. A slide, butterfly, or pin gate are recommended to prevent material from flushing off the belt at first fill.

Dust can accumulate at the head pulley and work its way back into the weigh belt enclosure, creating problems with the weighbridge, bearings, and belt support idlers. If enough dust builds up between the inside strands of the belt, it can create belt track issues or accuracy problems by changing the belt tension. Adequate dust venting is important for long-term maintenance of the weigh belt and high accuracy.

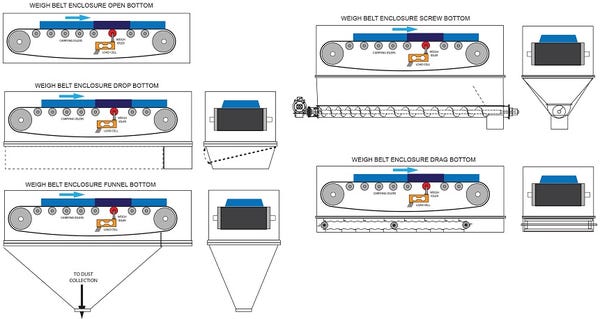

9. Weigh belts with enclosures are typically open on the bottom. Obviously, if open, dust or material can escape the enclosure creating house cleaning issues or violation of state or federal OSHA and MSHA standards. Belt feeders can be completely enclosed using several different methods.

o Drop bottom panels: This is the least expensive method of enclosing and while it does prevent material from escaping the enclosure, operators must be wary of making sure the bottom is cleaned on a regular basis, which is not always accomplished.

o Funnel bottom: This is an effective way to collect dust. The funnel is connected to a dust collection system and the dust is siphoned off. A big drawback is the funnel bottom requires steeps side walls to make the material not accumulate, so it takes up additional head room.

o Screw bottom: An effective way of getting rid of dust build-up. Like the funnel bottom, it requires steep side walls to bring the material into the screw.

o Drag conveyor: Also an effective way to keep the belt feeder clean. Requires minimal head room.

Summary

So, the next time you have an application for feeding materials, you should keep an open mind about using either a loss-in-weight feeder or weigh belt feeder. If properly applied, both feeder styles will provide high accuracy and dependability. The key is to pay attention to the details of the application and make sure that the chosen system best meets the needs. Neither system is better than the other. It comes down to which system best meets all the application parameters, be it, feed rate, material characteristics, space requirement, compatibility with the existing process, instrumentation communication, etc.

Tom Picone is director of business development at Vibra Screw Inc. (Totowa, NJ). Vibra Screw manufactures material handling equipment, including loss-in-weight feeder, weigh belts screw feeders and bin dischargers. For more information, email [email protected] or visit vibrascrew.com.

You May Also Like