Weighing Focus - July 2010

July 14, 2010

Check-Weighing Systems

WeighChek series of check weighing systems incorporates up-to-the-minute processing technology to provide industry leading levels of accuracy, ease-of-use and reliability. Improved technical performance, simplified ease-of-use, and enhanced integration with management information and quality control systems were the three key objectives in the development of this series. The machines are easy to install, easy to use, and easy to integrate. Lock Inspection Systems Inc., Fitchburg, MA 800-227-5539 www.lockinspection.com

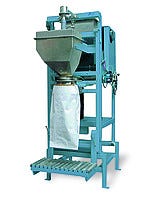

Dual Auger Scale with Digital Controls

The Model APO dual auger scale is designed with variable speed augers perfecting the art of “bulk and dribble” weighing. The T-3000 weigh controller allows the packer to feed material at three sequential speed settings which results in faster and more accurate measurements. This machine is ideal for powder ingredients and flours. The unit features cutting edge weighing accuracy and communication. Taylor Products, Parsons, KS 888-882-9567 www.magnumsystems.com

Truck Scale

Engineered with state-of-the-art robotics, the EPR+ Plus truck scale is available in impervious hydraulic or electronic load cell types and features durable baked-on, anti-corrosion powder paint. The legal-for-trade unit arrives fully-prepared for installation and includes DB75000 lb stainless steel load cells standard, which are factory assembled. All load cells can withstand the weight of up to 150% of published load cell capacity. A wide selection of capacities, platform sizes, and types are available. Cardinal Scale Mfg. Co., Webb City, MO 800-441-4237 www.CardinalScale.com

Click to enlarge

Heavy-Duty Weigh FeedersFor weighing and feeding up to 500 tn/hr with minimal maintenance and care, the DMO weigh feeder is ideal for a variety of heavy-duty industrial applications. A drive system, reducer, and motor are all directly mounted on the head pulley shaft. This provides for rugged, reliable, and safe operation while the need for alignments and maintenance is eliminated. At the heart of the unit is a direct multi-cell weighing system that does not use levers or counterbalance weights. This eliminates any chance of error during the weighing process. The DMO comes in standard belt widths of 24 to 54 in. with feed rate accuracies of ± ½% over a 10:1 range. These rates are achievable in a range of material particle sizes up to 4-in. lumps. Schenck AccuRate, Whitewater, WI 800-558-0184 www.accuratefeeders.com

High-Speed Net Weigher

The BEST Model NW-50 food-grade net-carton-filling system feeds 20-30 lb of snack food chips to 16x20-in. cartons at four cartons per minute with an accuracy of ±0.1 lb. Cartons are indexed into position, filled, vibrated, and moved out on a powered-roller conveyor. The machine features rugged, long-lasting components that require minimum maintenance. Metso Minerals Industries Inc., Brunswick, OH 800-827-9237 www.bestvibes.com

Continuous & Batch Weighing Systems

Vibra Screw offers a continuous or batching weighing solution for virtually any dry bulk feeding problem that addresses everything from main silo discharge to microingredient feeding. Accurate weighing of dry bulk solids requires reliable and consistent flow of material from storage into the feed mechanism itself. The use of controlled vibration promotes flow, uniformly densifies the material, and completely fills and empties each flight of the feed screw. As a result, all weigh feeding systems start as highly accurate volumetric feeders, eliminating inaccuracy during the refill cycle. Weigh feeders are available with screw sizes from 1⁄4 to 18 in. along with a range of belt, pan, and tube feeder-based systems. Vibra Screw Inc., Totowa, NJ 973-256-7410 www.vibrascrew.com

Bag Dump Weigh Batching System

This sanitary bag dump weigh batch station collects dust created during manual dumping of bulk materials from bags, boxes, drums, and other containers, and discharges bulk material by weight. A high-velocity vacuum fan draws airborne dust onto two cartridge filters. Automatic reverse-pulse filter cleaning maintains efficient, continuous operation by releasing short blasts of compressed plant air inside the cartridge filter on alternating cycles, dislodging dust build-up on outer filter surfaces. The hopper discharges into an integral flexible screw conveyor supported by a boom that cantilevers from the frame of the system, the entire weight of which is supported on four load cells, allowing loss-of-weight batching. A controller runs the flexible screw conveyor, first at high feed rate, then at dribble feed rate, stopping material flow once the accurate batch weight has been discharged. A mechanical hopper agitator improves the flow of material into the intake adapter of the flexible screw conveyor. Flexicon Corp., Bethlehem, PA 888-353-9426 www.flexicon.com

Click to enlarge

Continuous and Batch Mode Weigh SystemsThese weigh systems ensure reliable, repeatable, precision-weighed bulk containers, batch supplies, and finished packages. From material introduction to final packaging, in continuous or batch mode, the systems leverage the advantages of NBE integrated automation to reduce material waste, package re-work, labor, and inventory. They offer integrated, NTEP-certified weighing, accurate to +/- .01%, up to a total container capacity of 4500 lb. Available with RFID-based automation to recognize container type, batch type, and specific material recipe, the systems provide valid, accurate, and repeatable weighing in bulk container and bulk bag filling applications. A single, menu-driven HMI controls the system-wide automation. High-speed Ethernet communications deliver information to UL-listed panels. National Bulk Equipment Inc., Holland, MI 616-399-2220 www.nbe-inc.com

Force Measurement Suspension System

Force Measurement Suspension System

The Force Measurement Suspension System (FMSS) offers high accuracy in measuring weight using conveyor belt scales, weigh belt feeders, and loss-in-weight feeders. Available in a number of capacity ranges and configurations to suit the particular needs of continuous weighing and feeding equipment, the unit is effective in high-speed, high-volume to low-density, low-rate applications where control quality and productivity are critical. By providing mass counterbalance of tare weight, the FMSS creates a high signal-to-noise ratio in weight sensing that allows for precise real-time measurements that are not possible with standard scales. Thayer Scale-Hyer Industries Inc., Pembroke, MA 781-826-8101 www.ThayerScale.com

Minor/Micro Ingredient System

This system maintains accuracy regardless of supply bin capacity or the number of automated ingredients. Each module can feed and weigh from 1-12 ingredients; modules can be combined to provide 32 or more materials within a single system. These modules are able to process multiple scales simultaneously maximizing production speed. Continuous weigh blending can be provided when modules are integrated with a continuous mixing system. Multiple scale hoppers can reduce or even eliminate product cross contamination. The modular design allows for future expansion or modification. PC & PLC provides real-time batching data such as weights, batching status, alarm conditions, and batch history. Prater-Sterling, Bolingbrook, IL 630-759-9595 www.prater-sterling.com

Weight Controller

The HI 4050 general-purpose weight controller is easily configured to meet specific application needs such as filling/dispensing, batching/blending, check weighing, level-by-weight, and rate-of-change weight monitoring. The HI 4050 offers four-channel Analog, and Modbus TCP/IP network communications. Hardy Instruments, San Diego, CA 858-278-2900 www.hardyinstruments.com

You May Also Like