Technology Review 1406

July 14, 2010

Rotary Airlock Feeder

Rotary Airlock Feeder

The Dust Collector Series (DCS) rotary airlock feeder is an economical valve suited for general use under dust collectors, cyclones, and hoppers. This feeder has eight-blade rotors, precision machining, and rugged cast iron housing for efficient operation. In a case where pressure differential exists, such as when feeding pneumatic conveying lines, this unit is best suited for feeding the material accordingly. These particular airlocks maintain the highest level of performance for an extended period of time. The Quick-Take-Apart Series (QTA) rotary airlock feeder is made for applications where frequent removal of the valve internals is required. When encountering alumina, coke, fly ash, glass frit, and other highly abrasive products, the Ceramic Series rotary airlock feeder sustains its durability and achieves at least 3-5 times longer life compared with chrome and Ni-hard valves. Prater-Sterling, Bolingbrook, IL 630-759-9595 www.prater-sterling.com

Click to enlarge

Mass Flow MeterThe CentriFeeder with Integrated Control Valve (ICV) accurately measures and controls the flow of any dry, free-flowing solid. Using a highly customizable touch screen HMI equipped with an integrated Servo (low rpm, AC, brushless), a PID control loop is established to control the ICV feeding the patented CentriFlow meter. For precise measurement and control, an Integral Linear Position Sensor is used to regulate the blade’s position to within 1 part in 1000 (based on stroke). The blade’s movement can then be monitored via the CentriView electronics, or read manually via the mechanical indicator on the exterior of the valve. For delicate products, the CentriFeeder with ICV is equipped with a Virtual Flow Stop function that stops flow with virtually no damage to product. Eastern Instruments, Wilmington, NC 910-392-2490 www.easterninstruments.com

Mini Attritor Tank

Mini Attritor Tank

This 110-cc mini tank for laboratory attritors allows customers to process batches as small as 20-30 cc of material. The tank is now compatible with the model 01-HD/HDDM attritor, a high-speed laboratory attritor that combines benefits of the company’s standard 01-HD heavy-duty wet grinding mill with the advantages of using disks (rather than arms) and media as small as 0.1 mm or less. Union Process Inc., Akron, OH 330-929-3333 www.unionprocess.com

Click to enlarge

Four-Way Wye Line DiverterThe patented Quantum Series 4-way wye line diverter is specifically engineered to handle dry bulk solids in pneumatic conveying systems with vacuum or positive pressures up to 15 psig (1 barg). Available in 2- to 6-in. pipe or tube, it can direct dry bulk material from one source to four destinations, or converge from four sources to one destination. Precision laser cutting and bending technology is utilized to manufacture this valve. It provides a number of advantages over traditional flapper and rotating tunnel style diverters and eliminates trouble spots inherent in these conventional diverters. The wye line diverter provides superior sealing, low installation weight, fast “in-line” maintenance, and long-term, reliable service. Vortex Valves North America, Salina, KS 785-825-7177 www.vortexvalves.com

Tank Cleaning Machine

Tank Cleaning Machine

The HydroWhirl Orbitor is a versatile Clean-in-Place (CIP) rotating tank cleaning machine that combines high-impact cleaning efficiency with extended operating life, reduced life cycle costs, and simple on-site service. It is ideal for large tanks (up to 130 ft in diam) often found in the food, beverage, chemical, and pharmaceutical industries where superior cleaning with reduced cycle times and low water, energy, and chemical consumption are important considerations. Simplicity in design and operation offer a key advantage with the Orbitor. Unlike some competitive models, the Orbitor has a minimum number of moving parts and can be completely stripped and rebuilt for maintenance on-site in less than 15 minutes. Bete Fog Nozzle Inc., Greenfield, MA 413-772-0846 www.bete.com

Click to enlarge

Elevator BoltThe Reference (Ref) 70 style bolt is popular internationally for use in heavy-duty applications. Tapco manufactured the Ref 70 to accompany its existing styles: No. 1 Norway Flat Countersunk, No. 3 Eclipse (Slotted), Fanged, Pointed End Fanged and Western 3-Prong. The Ref 70 bolt is employed on pulleys over 20 in. in diam and is strongest when coupled with an oval washer, increasing the effective size of the bolt head and its holding power. The bolt is available in zinc-plated steel, with 18 sizes ranging from ¼-20 x ½ to 3⁄8-16 x 2½ in. Tapco Inc., St. Louis, MO 800-288-2726 www.tapcoinc.com

Flexible Ventilation Hose

Flexible Ventilation Hose

This flexible, general purpose, wire-reinforced Santoprene thermoplastic rubber hose is well suited for a wide range of ventilation and light bulk handling applications. Flexadux TR T-7 hose is medium-weight, reinforced with a spring steel wire helix, and highly resistant to chemicals, moisture, UV, and abrasion. Capable of handling toxic fumes, dust, sawdust, wood chips, and similar materials, this hose comes in 2- to 24-in. I.D. diam sizes and metrics in standard 25- and 50-ft lengths. Flexaust, Warsaw, IN 800-343-0428 www.flexaust.com

Click to enlarge

Gyratory Sifter with PortholesSifter Parts has developed an inspection porthole on its line of CS-1 gyratory sifters that allows easy access to visually inspect 100% of the screen area without the need to disassemble the sifter. The view port is easy to use and requires no tools; simply unscrew two wing nuts and remove the metal cover plate. The optional view port is available on select decks for the CS-1 sifter and includes front and rear side portholes with cover plates, self-adhering gaskets for the cover plates, and nylon wing nuts. Existing CS-1 sifter decks can be retrofitted during the repair process. The inspection porthole facilitates maintenance and sanitation as well as helps to extend the life of the gaskets and decks. Sifter Parts & Service Inc., Wesley Chapel, FL 800-367-3591 www.sifterparts.com

Laser Alignment Kit

Laser Alignment Kit

The Proline alignment kit is a visual laser system for checking and measuring straightness, flatness, squareness, parallelism, leveling, and many other tasks. The kit combines the features of a transit, an infinitely long straightedge, and laser alignment system all in one compact, portable, versatile product. The laser produces a crisp, collimated laser reference beam that forms a bulls-eye pattern for easy visual alignment and precise measuring. This laser is enclosed within a precision machined housing, ensuring that the laser reference beam is parallel to the side and base surfaces within 0.003 degree, or <0.030 in. at 50 ft. This level of accuracy is ideally suited for setting straight machinery runs, aligning production equipment, transferring mechanical points, locating shafts and bearing mounts, aligning belts and pulleys, etc. Pinpoint Laser Systems Inc., Peabody, MA 800-757-5383 www.pinlaser.com

Tubular Drag Conveyor

This tubular drag conveyor gently moves material in any direction from multiple inlets to multiple outlets. The totally enclosed design keeps material in the process and eliminates exposure of materials to the plant environment. A heavy-duty chain and flight design results in quiet performance with little need of service. The unit is ideal for conveying blended or friable products and has successfully handled a diverse range of materials, from hardened steel shot to pasta. Hapman, Kalamazoo, MI 800-427-6260 www.hapman.com

Gate Valves

Gate Valves

GatorGate Double-Dump valves feed and move chunky, fibrous, and abrasive material. These valves work with low-pressure air or gravity feed systems where standard rotary valves are prone to failure. Unlike other double-dump gate valves, GatorGates have spring-loaded gate arms, and the gates open and close alternately, thereby preventing air seepage and maintaining proper pressure. The standard cam-operated gate mechanism is actuated with an electric motor and offers a reliable alternative to pneumatically controlled valves. In comparison, pneumatic versions of competitive double-dump gate valves require large volumes of shop air for operation. Typical applications include dry material handling and bulk material handling in wood, scrap metal, plastics, cement, and various manufacturing industries. Aerodyne, Cleveland, OH 800-358-7546 www.AerodyneUs.com

Click to enlarge

Centrifugal Impact MillThis sanitary centrifugal impact mill (pin mill) provides coarse to fine grinding (325 mesh) of friable materials into controlled particle sizes, plus lump breaking and conditioning of fibrous materials. High-speed rotation of the inner disc accelerates material entering the central inlet of the opposing stationary disc. Material travels to the periphery of the discs at high speed through five intermeshing rows of rotating and stationary pins, with tight particle size distribution obtained by controlling the rotor speed. Munson Machinery Company, Inc., Utica, NY 800-944-6644 www.munsonmachinery.com

Pharmaceutical Metal Detector

The Insight PH is offered with advanced plug and play architecture featuring an array of new communications options – USB, SCADA, Wireless, and Standard Ethernet - designed to meet the requirements of both systems integrator and end user. The system occupies the smallest machine footprint in its class, now featuring a newly designed, compact integrated digital head with advanced Optix detector management software. Lock Inspection Systems Ltd, Oldham, Lancashire, UK +44 (0) 161 624 0333 www.lockinspection.com

Click to enlarge

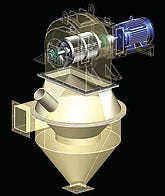

ClassifierThe ACS–TD classifier is now manufactured in 10 sizes ranging from the laboratory machine that handles up to 50 lb/hr to the ACS-300TD capable of feed rates in excess of 200 tn/hr. The TD or twin discharge series represents a breakthrough in increased fine particle production rate versus optimized classifier size. Airflow and particle behavior are predicted using state-of-the-art finite element-based flow modeling software and empirically verified through on-site laboratory testing. The cut point of the fine product can be precisely controlled by varying the rotational speed of the classifier blades. RSG Inc., Sylacauga, AL 256-378-3836 www.airclassify.com

Size/Density Separator

The Vibro-Air size/density separator employs vibratory screening to remove undersize particles, and airflow to simultaneously remove low bulk density materials. It is said to efficiently separate: fines and chaff from grain products; fines, angel hair, strands, and film scrap from plastic pellets/regrind; fibers, saw dust, and wood flour from wood chips/shavings; and other undersize and low-bulk density matter from on-size products. Material fed through a port on the unit’s hood cascades over a series of strategically placed internal trays and ultimately onto a vibrating, fine mesh screen that moves on-size material in controlled flow patterns toward and through a discharge port at the screen’s periphery. Heavier fines and a portion of the lighter fines pass through the screen onto a chute leading to a lower discharge spout. Simultaneously, air drawn into the base of the air-tight chamber flows upward, drawing the balance of low-density fines, along with airborne dust, fibers, and strands, into an airstream that increases in velocity (as the hood tapers) before venting to a cyclone and/or dust collector. Kason Corp., Millburn, NJ 973-467-8140 www.kason.com

You May Also Like