Powder Cohesiveness and Arching Potential

December 2, 2011

By Robert G. McGregor, Brookfield Engineering Laboratories Inc.

|

“Consolidation” is the word used most often to describe what happens to powder in hoppers. The weight of the powder in the containment vessel, whether a small feeder for tablet presses or a large silo for food powder storage, bears down on the powder in the hopper region and causes compaction. Voids between powder particles disappear as air is squeezed out and the powder gains cohesiveness as the particles move closer to each other. Technically speaking, this is equivalent to the powder gaining strength, because the sliding friction between powder particles moving against each other oftentimes increases as a consequence. The net result is that the flow behavior may become more difficult and interruptions in steady flow could result.

When powder in a hopper undergoes sufficient consolidation, it has the potential to form an arch, or stable bridge, which becomes an obstacle to the moving powder particles trying to go through the hopper opening. An instrument which can measure the capacity of powder to build an arch is known as a “shear cell” (image to the left). This device compacts a powder sample to varying degrees of consolidation, and then shears the particles against one another to measure the interparticle friction. If the friction is high enough, the powder could become cohesive to the point where it can form a solid mass of sorts, much like a snowball that is compressed between your hands. This ability to build a stable structure is known as “arching potential”.

|

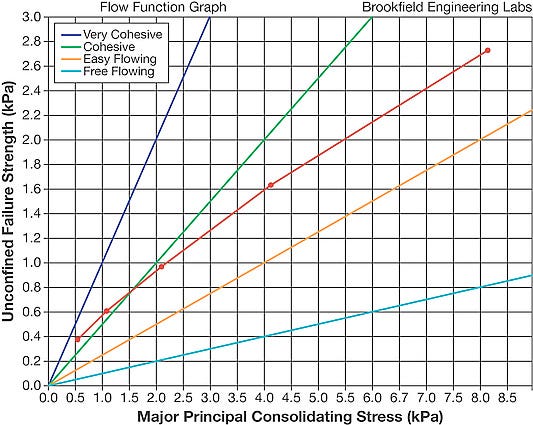

Figure 1 |

The annular shear cell is based upon a well-established method initially defined in ASTM D6128 to test powders for flow behavior and arching potential. The Flow Function, initially established for use in the minerals industry, has expanded over the past 50 years for application to powders in general. Failure strength of the powder is plotted against consolidation stress (see Figure 1). The powder processing industry has agreed to apply indices to the flow function graph that explain the type of flow behavior, ranging from “non-flowing” closer to the y-axis to “free-flowing” along the x-axis. The all-purpose flour in Figure 1 is highly cohesive at low consolidation stress and transitions to cohesive flow behavior at higher consolidation stress.

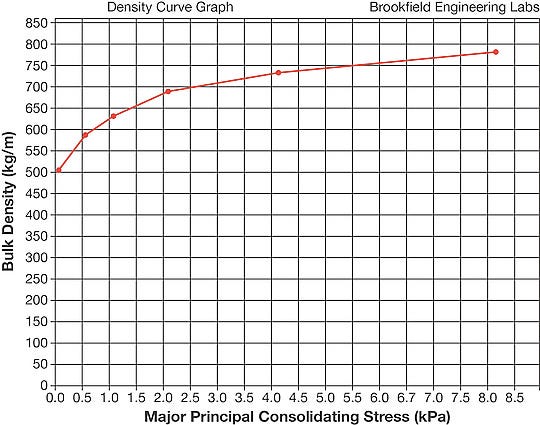

Density of the powder is a key parameter in the calculations that go into determining the flow function. Common sense tells us that powder density is obviously affected by increasing consolidation (see Figure 2). When the flour is first placed in the shear cell, the natural condition is referred to as “loose-fill”, which means that the powder has not undergone any compaction. Spacing between powder particles is at a maximum. As the powder is compacted, which reflects the situation where the flour fills up a bin, settling takes place due to the powder’s self-weight. Consequently, the density increases as a function of increasing consolidation stress. In the case of the flour, the compaction amounts to a change in density almost 50% from the initial loose-fill condition to the maximum density at the highest consolidation stress.

|

Figure 2 |

Scientists have developed analytical tools using the flow function data to predict the arching potential for powder. The shape of the curve in Figure 1 shows that the ratio of the powder’s failure strength relative to consolidation stress is decreasing at higher consolidation stresses. There is a critical consolidation stress at which the powder has the greatest likelihood to form a stable bridge. In the case of the all-purpose flour, it is most likely to occur in the “very cohesive” region on the flow function graph. This critical stress is calculated automatically by software that both controls the shear cell and collects the data for further analysis. The algorithms used in the calculations are generally agreed upon by scientists specializing in the subject of powder mechanics. The arching dimension in this case is 348 mm, or 13.7 in.

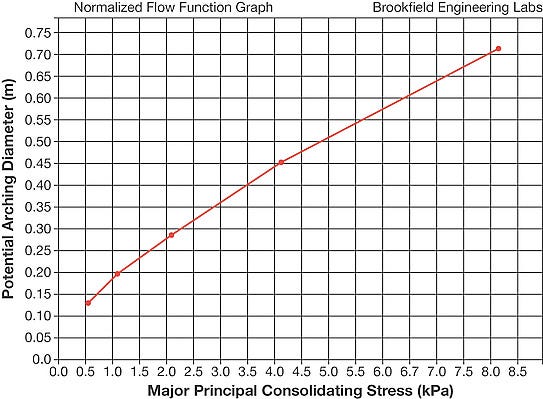

A more recent approach to this type of analysis is to look at “arching potential” as a function of consolidation stress. This takes into account the change in powder density that results from increasing consolidation. Figure 3 shows what is referred to as the normalized flow function for the flour, which is a snapshot of how the original flow function graph is adjusted to take into account the change in powder density. The graph shows how arching potential increases at higher consolidation stresses.

|

Figure 3 |

The practical application for the use of arching potential is to benchmark powders for flow behavior relative to each other. When a given batch of powder is known to process readily, future batches can be tested in the shear cell and the arching dimension values compared to the reference powder. If the value is significantly higher, this might imply that corrective action of some kind using flow aids is necessary before proceeding. Or at a minimum there is a need to alert plant operations that the upcoming batch may have greater difficulty with processing.

Powder processing is at a new crossroads with the tools that are becoming available to enhance operations. The exciting news about shear cells is that they can produce scientifically relevant data in short order, thereby providing quality control with the capability to make decisions on acceptability while materials are in process. Most significant is that the shear cell can be operated by any technician with less than an hour of training.

Robert G. McGregor is general manager, global marketing for Brookfield Engineering Laboratories Inc. (Middleboro, MA). McGregor holds M.S. and B.S. degrees in mechanical engineering from MIT in Cambridge, MA. For more information, call 508-946-6200, e-mail [email protected], or visit www.brookfieldengineering.com.

About the Author(s)

You May Also Like