Maximize Productivity with the Right Design of Your Flexible Screw Conveyor

December 14, 2016

INCREASING CONVEYOR

PERFORMANCE AND EFFICIENCY

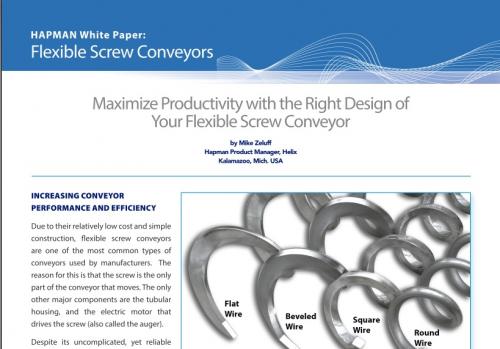

Due to their relatively low cost and simple

construction, flexible screw conveyors

are one of the most common types of

conveyors used by manufacturers. The

reason for this is that the screw is the only

part of the conveyor that moves. The only

other major components are the tubular

housing, and the electric motor that

drives the screw (also called the auger).

Despite its uncomplicated, yet reliable

construction and straightforward

operation, many end-users overlook

important factors that could potentially

lead to poor performance, excessive

power usage, severe wear, and material

degradation. For these reasons, it

is essential to consider all system

parameters when selecting conveyor

options. Only then can you ensure a

correct and successful installation that

achieves maximum operational efficiency.

You May Also Like