Vacuum Systems & Cleaning 112

June 6, 2007

Industrial Vacuum Kit

Industrial Vacuum Kit

An industrial vacuum hose and kit includes a 2½-in. industrial vacuum hose (25 ft long), two cuffs, and a five-piece nozzle kit that includes a crevice tool, a 14-in. wide floor nozzle, a dust brush, a bench nozzle, and a wand. The kit attaches directly to existing ductwork with a saddle-tap tee. Users only need to install the saddle, add the 3-in. blast gate, and connect the hose with one of the cuffs.

Air Handling Systems, Woodbridge, CT 800-367-3828 www.airhand.com

Industrial Central Vacuum System

Industrial Central Vacuum System

The MAC VAC has multistage centrifugal exhausters that allow multiple-user applications. Positive displacement pumps facilitate bulk-spill cleanup. Regenerative exhausters are available for single-user situations. Separator options include dirt-can, hopper-bottom, or bin-vent style; bag or cartridge filters; horizontal or vertical filter orientation; clean or dirty side-filter exchange; and tangential, radial, rock-box, and high-entry inlets.

MAC Equipment, Kansas City, MO 888-821-2476 www.macequipment.com

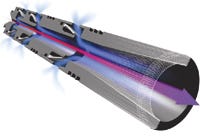

Pneumatically Driven Vacuums

Pneumatically Driven Vacuums

The CFM A15 and CFM A17 vacuums provide suction, filtration, and durability while operating without electricity. The units connect to any compressed-air system and use air pressure driven through a venturi to create suction powerful enough to handle even large debris. The CFM A15 is compact and maneuverable, well suited to confined spaces and transportation to remote locations. The larger CFM A17 can handle heavy-duty chores and features a large 26-gal tank. Because the venturi has no moving parts, the unit requires little maintenance, making it suitable for continuous-duty applications such as powder coating production lines. The A17 is also available in an explosion-proof model with conductive wheels and nonsparking conductive accessories.

Nilfisk-Advance America, Malvern, PA 610-647-6420 www.pa.nilfisk-advance.com

Vacuum Cartridges

Vacuum Cartridges

Patented COAX technology provides increased efficiency and productivity during industrial vacuum applications. It is suitable for material-handling applications, including electronics production, packaging or palletizing, pharmaceutical, or food processing. The ejector technology is based on a multistage concept for creating vacuum with compressed air. By integrating the internal components of a multistage vacuum pump into a vacuum cartridge, COAX allows for a smaller, more efficient, more reliable, and highly flexible technology. This flexibility is particularly helpful for users who plan to design a modular system to address specific application needs. Because these vacuum cartridges are up to twice as fast as other cartridges and provide three times more flow than a conventional ejector with the same air consumption, vacuum pumps are able to provide high performance even at low or fluctuation feed pressures (25–90 psi).

PIAB USA Inc., Hingham, MA 800-321-7422 www.piab.com

Portable Vacuum Station

Portable Vacuum Station

This self-contained heavy-duty, portable vacuum station can be used for a wide range of applications around a plant or laboratory. The station features a reservoir and the VPE-48 Electric Vac-Pack dry, oil-free vacuum pump, which are fully integrated and mounted on a steel cart with heavy-duty wheels and casters and a rugged push handle. Designed for applications periodically requiring a remote vacuum station, this high-capacity portable unit can be equipped with a 1.5-, 3-, or 5-hp motor and pull a 24-in.Hg vacuum with 24, 50, or 75 scfm. Suitable for use with custom jigs, fixtures, special lifters, hold-down clamps, and evacuation or degassing systems, the station has energy saver circuitry that allows the pump to shutoff automatically when the proper vacuum

is reached and stays constant above a preset level.

Anver Corp., Hudson, MA 800-654-3500 www.anver.com

Vacuum Loader

Vacuum Loader

The Model 3302E vacuum loader features a positive-displacement vacuum pump with a 20- to 40-hp motor for fast cleanup of conveyor spillage, broken bulk bags, overfilled or clogged process vessels, or residual material in storage silos. The unit is highly mobile because of its jack-leg filter separator, which raises into position for high-volume recovery and then lowers to a transport position for movement through a 10-ft overhead door. The loader can be used with self-dump intercept hoppers or vacuum-tight roll-offs. It can be used for direct loading of bulk bags.

Vac-U-Max, Belleville, NJ 973-759-4600 www.vac-u-max.com

Portable, Stationary, and Trailer Vacuums

Portable, Stationary, and Trailer Vacuums

Vacuums are manufactured in portable, stationary, and trailer designs. Horsepower ratings vary from 3 to 250. The standard vacuum pump drive is an electric motor, with LP gas, diesel, or gasoline engines available as options. All models feature a no-tools-required bag and cage removal system that permits one person to access these components in five minutes for inspection and permits removal and placement of bags and cages in 30 minutes. Bag or cartridge filter cleaning is performed using a state-of-the-art on-demand system that pulses only if the differential rises to the cleaning range. The

pulsing can be varied to contend with very fine dust. Materials handled include abrasives, asbestos, carbon black, cereals, chemicals, coal, fertilizer, flour, grains, limestone, and plastic pellets.

Multi-Vac Inc., Union Grove, WI 888-488-4188 www.multivacinc.com

Explosion-Proof Vacuum Cleaner Systems

Explosion-Proof Vacuum Cleaner Systems

Company manufactures legally certified explosion-proof vacuum cleaner systems for hazardous locations and environments Class I Groups C and D and Class II Groups E, F, and G. The all-stainless-steel construction can endure even the harshest environments. Detachable tank models are user-friendly and have an ergonomic design. Features include a static-dissipating main filter, an extralarge static-dissipating prefilter, conductive poly liners for the safe disposal of recovered materials, a manual filter shaker that dislodges the accumulated caked-on dust from the filter, a HEPA filter with 99.995% capacity at 0.3 µm (IEST RP-CC001.3 tested) for the recovery of nuisance dusts, and a static-dissipating suction hose and tool kit. Sizes range from 10 to 55 gal. Other filter-cleaning options include manual reverse purge, automated reverse pulse, and automatic purge.

Tiger-Vac Inc., Dania, FL 800-668-4437 www.tiger-vac.com

You May Also Like