Two Processing Technologies Combine to Solve a Common Drying Problem

February 1, 2008

|

The Vibroflash fluid-bed dryer |

Prior to beginning design of a complete dryer system, Carrier Vibrating Equipment Inc. (Louisville, KY) performs confirming drying tests in its Louisville laboratory. The testing proves the viability of the drying process and allows engineers to confirm key design criteria such as the required hot-gas volume, dryer dimensions, and maximum fluidizing velocity. Although these tests often involve unique application challenges, they also present exciting opportunities for new product development.

For example, a recent test application required drying a fine (average particle size of 2–3 µm) calcium carbonate filter cake. The cake was presented to the dryer in the form of a hard lump. It was hoped that the lump would break up when introduced to the hot-gas stream, but it did not. When tested in Carrier’s Tornesh dryer, the lump did break up but degradation took too long and made that option unviable. The addition of a cage mill to the flash dryer was considered, but this idea was eventually dismissed, since it would not produce dry material in its discrete particle size, and additional milling would be required. The average particle size was too small to be used in a traditional fluid bed.

The ultimate drying solution combined the benefits of two readily available drying technologies: vibrating fluid-bed processing and flash drying.

Fluid-Bed Processing

Vibrating and nonvibrating fluid beds are used throughout many industries for drying wet powders and granulated materials. The primary benefits of this process are consistent product quality and energy-efficient operation.

Fluid-bed processors operate by passing hot gas through a membrane that supports a “bed” of wet material. The hot gas envelops each wet particle, causing the material to flow freely about the bed. Energy efficiency is excellent because heat transfer is continuous at all times on all surfaces of the particle. In turn, product quality is good because mixing of the bed prevents hot or cold spots.

The velocity at which the hot gas passes through the membrane is called the fluidizing velocity. The ideal fluidizing velocity is one that actively turns and mixes the bed without entraining a substantial amount of material (typically up to 10%) in the exhaust gas leaving the fluid bed. In general, materials with larger mean particle sizes or very dense materials use higher fluidizing velocities. Smaller or lighter materials use low velocities. A fluid-bed manufacturer attempts to find the maximum fluidizing velocity in order to minimize the size and cost of the fluid bed.

For wet materials with a fairly narrow particle-size distribution, a conventional, nonvibrating fluid bed works well. If the particle-size distribution is broader, with very small and large particles in the wet feed,

a vibrating fluid bed is more appropriate. The addition of vibration allows the designer to operate the fluid bed with a fluidizing velocity appropriate for the mean particle size rather than the maximum particle size. The vibration helps to move large particles that don’t fluidize well to the discharge of the unit. The large particles would likely fall to the bottom of a conventional fluid bed and have difficulty discharging from the dryer.

Flash Drying

Neither vibrating nor conventional fluid beds are ideal for fine powders. Wet materials with an average particle size of less than 50 µm are typically not dried in fluid beds unless the density is high or a very long residence time is required. These fine powders can be processed in a number of different dryers including flash dryers, paddle dryers, and rotary dryers. Carrier typically offers its flash dryer or Tornesh dryer when the wet feed is very fine.

The common flash dryer consists of a high-velocity hot-gas stream that passes vertically through a narrow duct. Wet feed is introduced at the bottom and carried vertically to a dust collector, where it discharges as a dry powder. The Tornesh dryer is a variation of a flash dryer that is designed to provide longer residence times and improved energy efficiency.

Combining Fluid-Bed Processing and Flash Drying

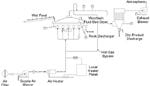

|

Illustration of the Vibroflash process flow |

To solve the application challenge of effectively and precisely drying the fine calcium carbonate filter cake, Carrier looked to combine the advantages of both fluid-bed processing and flash drying.

A vibrating fluid bed was used to process the material in its initial wet state because it was introduced to the dryer in the form of lumps that would not fluidize. As the lumps moved toward the discharge of the dryer, they were exposed to the hot fluidizing gas passing around them. The combination of the vibration and the loss of moisture caused the lumps to break into smaller lumps. An attrition chamber was created inside the dryer to prevent the lumps from passing all the way to the discharge.

Lumps in the attrition chamber were constantly exposed to the hot process gas while they bounced and abraded against one another. Throughout the entire process, fine particles were released from the lumps and entrained in the exhaust gas, passing to the primary dust collector. Almost all of the wet feed was eventually dried and entrained in the exhaust gas. A very small amount of material (less than 0.05% of the wet feed) in the form of hard agglomerates and contaminants remained in the attrition chamber after several hours of continuous operation.

The moisture content of the dry material discharge from the dust collector was slightly above specification. To achieve the required discharge moisture specification, the exhaust duct from the vibrating fluid bed to the dust collector was lengthened, and a small amount of hot gas was bypassed around the fluid bed to the duct, essentially creating a flash-drying duct.

The Vibroflash Dryer Is Born

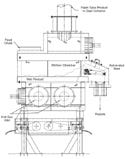

|

Mechanical drawing of the Vibroflash fluid-bed dryer |

The resulting device is a patent-pending machine called the Vibroflash fluid-bed dryer. The production version of the Vibroflash includes an attrition chamber with an automated discharge weir that periodically releases contaminants from the drying chamber. As an option, a hot-gas bypass duct can be added to achieve lower discharge moistures. The valve in the duct can be automated to provide the required discharge moisture content without overheating the product. Additional control variables include the hot-gas velocity and temperature, the vibration intensity, and the fluid-bed angle of vibration.

Each of these parameters has an important function. The hot-gas velocity can be adjusted to process materials with varying particle sizes. Hot-gas temperature is automated and controlled off of the exhaust gas temperature to provide dry material at the dust collector discharge. Vibration intensity can be adjusted to provide more vibrational force for materials that form hard lumps. Perhaps most important to providing an energy-efficient operation is the ability to adjust the angle of vibration to control the speed at which wet material flows through the machine. The drying system operates most efficiently when the entire fluid bed is filled with wet material from the attrition chamber back to the charge end so that hot gas is constantly passing through the wet material.

At the time of this writing, another Vibroflash was being fabricated for a building-products supplier that processes gypsum. The Vibroflash was successfully tested during the quotation stage of the project on a continuous basis, producing several tons of dry product. The unit will replace a much larger rotary dryer and reduce energy consumption by approximately 40%. The Vibroflash achieves its energy efficiency because 95% of the moisture is removed in the fluid bed, where moisture is most efficiently removed. The unit will also process wet feed that sometimes contains rocks and frozen lumps that cannot be wet-screened prior to drying. The frozen lumps eventually discharge as good powder while the rocks are periodically discharged from the attrition chamber into a tote.

The Vibroflash is intended as a cost-saving alternative to rotary dryers and air-swept mills, processing wet powders in the form of wet cakes or lumps. It is useful for lumpy or agglomerated wet materials that are too fragile or too sticky to be sized in a mill prior to drying. It is also ideal for drying wet materials that contain heavy contaminants such as trash or rocks that must ultimately be removed from the final product.

Carrier Vibrating Equipment Inc., Louisville, KY, manufactures both vibrating and nonvibrating process machinery. The company has extensive experience in the processing of wet powders and bulk solids. Its product line includes vibrating and nonvibrating fluid beds, flash dryers, media slurry dryers, indirect dryers, and a Tornesh dryer. For more information call 502-969-3171 or visit www.carriervibrating.com.

You May Also Like