Powder & Bulk Solids Toronto Equipment Preview

April 19, 2019

Powder & Bulk Solids Toronto takes place June 4-6, 2019 at the Toronto Congress Centre in Toronto, Ontario. Attendees will see the industry’s latest innovations, processes, and materials. The expo floor will include everything from material handling to regulation and safety, silo and bin design to combustible dust hazards and mitigation.

Part of Advanced Design & Manufacturing (ADM) Expo, the event will include representatives from automation technology, design and manufacturing, packaging, and plastics. Based on attendee feedback, representatives from these most-requested fields will be part of the expo: automation, contract manufacturing, energy efficiency & sustainability, molding & thermoforming, material handling, packaging, robotics, testing, training & education.

Powder Show Toronto features everything needed to eliminate costly mistakes and maximize productivity and profits, including bulk blending, combustible dust hazards & mitigation, dust collection & removal, material handling & transport, pneumatic conveying, pollution control, powder technology, regulation & safety, silo & bin design, mixers & blenders, valves, dryers, and feeders.

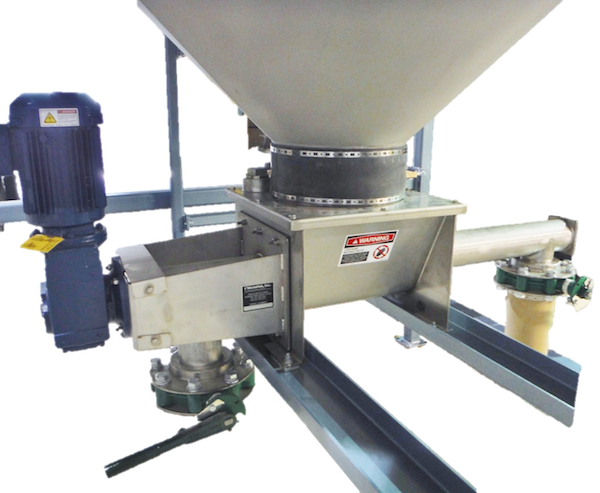

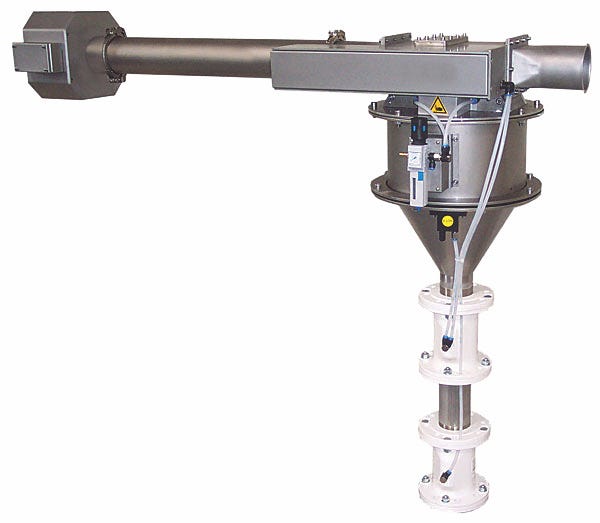

Dual-Outlet, Heavy-Duty Volumetric Feeder

Metalfab’s dual-outlet, heavy-duty volumetric feeder, in conjunction with the Metalfab Posibin, meters powder with near gravimetric accuracy. Eliminates downtime disassembling upstream/downstream equipment to reclaim unused material. A flip of the switch reverses the feeder screw to empty your bin and receive the reclaimed material back into inventory. Stainless steel; mill finish; Ø4-Ø16 in.; manual or automated discharge valves on each outlet.

Metalfab MHS

973-764-2000 www.metalfabmhs.com

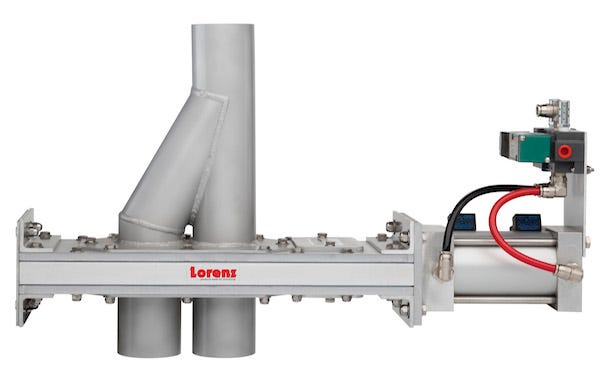

Pneumatic Conveying Components

Booth 125 - Lorenz offers a full line of components for vacuum, pressure, and gravity conveying systems, including: diverter valves, slide gates, maintenance gates, couplings, elbows, fittings, and cyclones that are ideal for dry bulk conveying in dilute phase systems. Iris valves were recently added. The products are used in applications in multiple industries, including plastics & packaging, food & pet food, chemical, grain milling, minerals, etc. Quick deliveries for customized configurations include space constraints, corrosive applications, hazardous locations, high temperatures, and outdoor installations.

Lorenz Conveying Products, Cobourg, ON, Canada

800-263-7782 www.lorenzproducts.com

Condux Impact Mill

Booth 152 - The Condux impact mill is a highspeed fine impact mill for the dry grinding of various products up to a Mohs hardness of 3-3,5. The diversity of grinding tools allow the mill to be used universally depending on the application and area of operation. This also applies when circumstances such as product characteristics or requirements have changed. The grinding tools can easily be changed as well. Depending on the application and product, the mill is equipped with differing rotor and stator variations and can be operated as any of the following mill types: pin mill, blast mill, beater mill, or attrition disc mill. One design variant with two housing doors can be used either as a single rotor or a counter-rotating pin mill.

Netzsch Premier Technologies LLC, Exton, PA

610-280-1220 www.netzsch.com

Get information or register for Powder Show Toronto, June 4-6, 2019

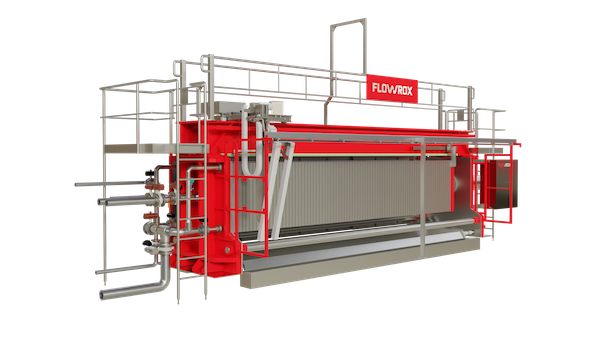

Filter Press

Booth 154 - The Flowrox filter press offers a fully automatic pressure filter and a long-term solution to maximize production, reduce downtime, and lower costs. It has optimal equipment and sizing options, as well as the option to enhance your production with Flowrox Smart Solutions. With the smart filtration digital service, operators can optimize filtration process, increase production volume, and detect failures before they even occur. All that can be done from anywhere with any computer, smart phone, or other handheld device with internet connection. It also comes with complete lifetime support from Flowrox filtration experts.

Flowrox Inc., Linthicum, MD

410-636-2250 www.flowrox.com

Explosion Isolation Flap Valve

Booth 233 - The IEP Technologies IsoFlap valve is NFPA 654, 69, and EU ATEX Directive compliant explosion isolation solution that mitigates explosion propagation risks to upstream equipment. It is an effective, self-actuating device providing inlet explosion isolation to protected vessels handling combustible dusts such as dust collectors, cyclones, and other process equipment.

IEP Technologies

855-793-8407 www.ieptechnologies.com

Vertical Form, Fill & Seal Metal Detector

Booth 147 – Eriez offers a new and improved Xtreme vertical form, fill & seal (VFS) metal detector. This compact unit requires no metal-free area above or below the sensing head, making it ideal for installation in the space-restricted area before the hopper and forming tube. The new and improved unit eliminates the need for costly modifications and plastic hoppers. With its design, this metal detector connects directly to a customer’s existing stainless steel hopper and forming tube with simple Jacobs connectors. The metal detector meets stringent standards for food processing environments and offers high sensitivity. Suitable for washdown, it detects millimeter-sized metal spheres and feature food grade pipe and stainless-steel construction. It is available in 3-, 4-, 6-, 8-, and 10-in. aperture sizes to meet practically any application need.

Eriez, Erie, PA

www.eriez.com

Industrial-Grade Magnetic Separation

Booth 121 - Industrial Magnetics Inc. (IMI) offers a variety of industrial-grade magnetic separation solutions for removing large to fine metal particles from mechanically conveyed and gravity-flow processing streams. These magnets can be placed before and/or after mechanical conveyors to protect equipment and purify product, including the drawer-in-housing, the large tube housing, the OX, and the RotoDrawer. Every product features the new Opti Series of magnetic circuit choices, ranging from 52-55 MGOe, as well as gauss and mechanical wearability ranges designedto meet and address the exact needs of all applications. IMI considers processing conditions like high moisture content, particle size and abrasiveness, bridging, galling, temperature extremes and humidity levels when recommending a magnet.

Industrial Magnetics Inc., Boyne City, MI

231-582-3100 www.magnetics.com

High-Efficiency Industrial Grinder

Booth 261 - Szego Materials Engineering Inc. produces three sizes of The Szego Mill, a high efficiency industrial grinder. It offers 30x greater volume capacity of a similar-sized ball mill, using up to 50% less power. The Szego Mill is a modular unit and allows tool-free maintenance, cleaning, and swapping of parts to change between jobs in minutes. Customizable grinding rollers with an average 10-year lifespan give fine control over particle output size and distribution. There is no grinding media to replace. Invented in 1971 by Laszlo Szego, this machine has been heavily developed and refined over the last four decades by Dr. Prof. Olev Trass of the University of Toronto Applied Chemical Engineering Dept. Although never previously commercialized, the Szego Mill has been the subject of more than 20 commercial pilot projects throughout the world. These have resulted in more than 30 patents and over 100 published research papers that conclude that the Szego Mill offers high cost savings and return-on-investment when used with materials ranging from coal and oil fuels, to pulp and paper; anaerobic digestion of wastes; protein, oil, and mineral extraction; food processing and more.

Szego Materials Engineering Inc., Toronto, ON, Canada

647-988-3825 www.szegomill.com

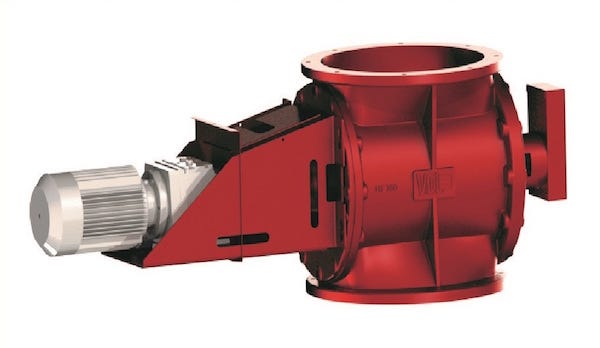

Certified Rotary Valves

Booth 166 - The EcoMAXX EMRVEX line of NFPA 69-compliant ATEX explosion tested and certified rotary valves provide effective explosion isolation for industrial filtration, pneumatic conveying, and bulk handling processes. Standard, medium and heavy-duty designs with multiple rotor tip options are available. All EM-RVEX rotary valves are ATEX Certified EN 15089 & NFPA 69 Compliant. Sizes include 10, 14, and 18 in. They are certified to withstand explosive pressures up to 24.66 psi. Features include: 8-vane rotor with Vulkollan (polyurethane) flex tips; cast iron housing with flanged inlet/outlet; direct drive motor with flexible coupling and gearbox. Options for variable speed controller, flange gaskets, isolation box, air purge seals, special plating such as chromium or nickel, stainless steel construction and quick disassembly are available.

Boss Products LLC, Schertz, TX

210-664-4200 www.bossproductsamerica.com

pTRON 05 Metal Detector

Booth 131 - Built specifically for pneumatic operations in the powder & bulk solids industry, the pTRON 05 metal detector is designed for installation in suction or pressure lines for either horizontal or vertical applications. It detects contaminants in granular food product lines and is able to detect a wide variety of contaminants such as ferrous, stainless steel, aluminum, copper, brass, and more. This high-performance application is easy to operate, maintenance free, and fast-acting. The pTRON 05 is comprised of the detection coil with the electronics safely encased in housing. There is a minimal loss of good material thanks to the fast-acting flap reject.

Bunting Magnetics Co., Newton, KS

316-284-2020 www.buntingmagnetics.com

For more news headlines, articles, and equipment reviews, visit our Equipment Zones

You May Also Like