Valves, Gates, & Airlocks 1829

June 7, 2011

Flex Tip Airlock

Flex Tip Airlock

Booth 846 - Fabricated to meet the needs of the industrial workplace, this airlock’s design is based on customers’ rugged applications and is built to outlast other airlocks. The standard 8-vane rotor design offers the tightest seal of any flex tip airlock. Features include variable speed selection, wiper material, and inlet/outlet size. Seventeen different models are in stock and come with either round or square flanges. An entire inventory of replacement parts is stocked at all times. Imperial Systems Inc., Jackson Center, PA 800-918-3013 www.isystemsweb.com

Easy-to-Clean Rotary Airlocks

Easy-to-Clean Rotary Airlocks

Easy Clean rotary airlocks are used in applications requiring frequent cleaning of the valve internals. The rotor is easily removed without any hand tools, allowing the operator to remove quickly. These units also feature scalloped rotor pockets, where the bottom of the pocket is smoothed out and eliminates any cracks or crevices for material to accumulate. The valve internals can be polished to whatever specification is required. Optional slide rails are also available. Carolina Conveying Inc., Canton, NC 828-235-1005 www.carolinaconveying.com

Rotary Airlock Valves

Rotary Airlock Valves

These rotary airlock valves are designed for sanitary pneumatic conveying systems operating within -15 in. Hg to +15 PSIG with 6- to 12-in.-capacity options. The standard 9-blade rotor positions two blades to always be in contact with the discharge side of the housing to provide a superior seal. The horizontal micro adjust system allows the rotor to be precisely centered for reliable rotor positioning. The EZ-slide, tool-free take-apart rotor removal system provides easy access to the interior of the valve and rotor. All cast 304/316 stainless steel housing meets USDA sanitation standards. Options include, 10-blade rotor, shallow rotor pockets, rotation detection switch, bolt on rotor tips, side housing air vents, and air purge. RELCO LLC, Willmar, MN 320-231-2210 www.relco.com

Rota ry Airlocks

ry Airlocks

Rotary airlocks are available from the Type 1 standard, yet versatile, version to the Type 6 built with rugged NiHard steel to withstand the most abrasive materials and applications. Since each application is different, a complete line of rotor options and accessories is available. Smoot will customize the rotary airlock to fit your application using open or closed rotors, relieved tips, reduced capacity rotors, chrome or Teflon coatings, round and square flanges, flex tips, high temp, abrasive resistant tips, vented inlet and more. Smoot, Kansas City, KS 800-748-7000 www.magnumsystems.com

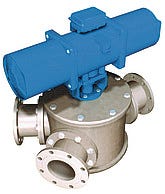

In let Valve

let Valve

The DEPAC inlet valve is a replacement for the UCC Fläkt dust inlet valve. The DEPAC inlet valve delivers improved sealing performance, extended service life, and greater reliability. It is used for vessel isolation service in high-pressure pneumatic conveying of dry ash and other abrasive materials. The dense-phase system is designed to convey large quantities of material, up to 200 tn/hr, over distances of 5200 ft. The automated control system maintains constant conveying air mass flow in the pipeline at low velocities, which helps prevent plugging while minimizing abrasion, maintenance, and power consumption. United Conveyor Corp., Waukegan, IL 847-473-5900 www.unitedconveyor.com

Co ne Valve

ne Valve

The Dense Flow cone valve is used in conjunction with the Dense Flow charging hopper as the main inlet and sealing valve for the Dense Flow conveying system. The charging hopper’s design eliminates head pressure and vents the displaced air when material fills the pressure vessel, thus allowing the single cone valve to completely seal the pressure vessel once full. Unlike a butterfly valve, the cone valve’s seal actually becomes tighter during pressurization. It is not uncommon for a Dense Flow cone valve to last 15 years or more before needing a seal replacement. JDB Dense Flow Inc., Palm Harbor, FL 800-822-3569 www.jdbdenseflow.com

Clean-in- Place Rotary Airlock Valve

Place Rotary Airlock Valve

Booth 731 - Designed specifically for sanitary applications, such as food processing or pharmaceutical processing, the Quick-Clean Series of rotary airlock valves aids in regulatory standards and practices compliance, reduces cleaning and sanitizing time, and simplifies inspection. This line of cast stainless steel rotary airlock valves features the RotorRail design that enables full validation access to the rotor and all internal surfaces of the housing without time-consuming disassembly of the endplate, or the concern for accurate rotor re-alignment during re-assembly. The stainless steel housings of these valves are cast in North America to ensure superior strength in the composition and solidification of the housing’s metallurgy. The stainless steel housings are then CNC-machined to precise tolerances. ACS Valves, Caledonia, ON, Canada 800-655-3447 www.acsvalves.com

Gate L ock

ock

Booth 425 - The Gatelock assembly is a low-maintenance alternative to the traditional rotary airlock feeder and provides a positive seal that can accommodate either full vacuum or pressure up to 100 psig. The air-operated seat inflates to provide a long-lasting, high-integrity seal and easily handles high cycling of dry granular or fine powdered materials. The seat automatically compensates for wear when it inflates against the disc, extending valve life. The Gatelock assembly is available in sizes from 2 to 30 in. in diameter and in any length desired. Posi-flate, St. Paul, MN 651-484-5800 www.posiflate.com

Gravity Diverter  Valve

Valve

Booth 2071 - To divert material from one source to three destinations in gravity flow applications, the 3-Way Seal Tite diverter offers a versatile solution. The diverter handles nonabrasive to moderately abrasive powders, granules, and pellets, and is ideal for food applications and others that require a dust-tight seal to minimize cross-contamination. Engineered to channel the flow of materials away from the leading edge of the flapper vane, the diverter maintains seal integrity and inhibits material leakage across the closed legs of the valve. While other flapper diverters may leak past the vane shaft and trap material underneath, the 3-Way Seal Tite includes live-loaded, polymer shaft seals to eliminate this problem. Made of durable carbon or stainless steel, it is available in 4- to 24-in. sizes. Vortex Valves North America, Salina, KS 785-825-7177 www.vortexvalves.com

Precision Rotary  Valves

Valves

Modular PMV rotary valves are available in severe-duty and ultra-duty versions for use in extreme industrial environments where typical valves do not last. Severe-duty models not only use piloted, flanged roller bearings to withstand radial thrust loading, but barrel sides and rotor are made from a 500 Brinell hardened alloy machined to three-decimal place tolerances. The barrel sides and end wear plates are plated with RW-90, an exclusive chrome-like alloy that lasts longer than chrome. For the harshest environments, the ultra-duty PMV is treated using an advanced metallurgical process for use in plants where coatings, such as hard chrome, are not desirable or when extreme wear has been a problem for other rotary valves. Precision Machine & Manufacturing, Eugene, OR 541-484-9841 www.premach.com

Rotor Detection  System for Rotary Valves

System for Rotary Valves

The Gen 2 Rotor Detection System (RDS) provides thorough protection against metal contamination. The new design solves the problem of detecting metal-to-metal contact within the rotary valve housing when conductive products are being conveyed or used for CIP. The system’s control module has adjustable set points for product and CIP solution conductivity. This allows CIP to be run with the rotor in place. The user just switches the system into CIP mode via a PLC output. The Gen 2 RDS can run in products ranging from dry powders to highly conductive products. A lower resistance set point monitors for metal contact even in the most conductive caustic and acidic solutions. The system can even be monitored in real time with a laptop or PLC to aid in troubleshooting. Nu-Con Equipment, Chanhassen, MN 952-279-5210 www.nucon.com

Knife Gate  Valve

Valve

The StopTight manual and pneumatic knife gate valve for dry solids, granules, and powders, is ideally suited for discharging dry, free-flowing materials from gravity-fed hoppers, silos, mixers, screw conveyors, and chutes. This valve is also an economical and reliable way to isolate airlock valves from hoppers during routine maintenance or emergency shut-downs. A series of adjustable cam-guides support the slide plate and seal it against the machined inlet seat. Aerodyne, Chagrin Falls, OH 800-358-7546 www.DustCollectorHQ.com

Round Maintenance  Gate

Gate

Booth 2146 - Lorenz is introducing a round maintenance gate. Expensive, heavy, square to round adapters have been eliminated, enabling product to flow smoothly. Available in sizes from 6-16 in., the round maintenance gate mounts above airlocks or below bins and hoppers to handle dry material during periodic shutdowns for maintenance. Lorenz Conveying Products, Cobourg, ON, Canada 800-263-7782 www.lorenz.ca

Ball  Diverter Valves

Diverter Valves

These ball-style diverter valves are built for multiple source convergence and multiple destination divergence of dry materials in either pressure or vacuum modes. The 3-way, vortex design is available in seven configurations to accommodate a wide range of piping layouts, and the valve’s actuator rotates up to 135º for maximum installation flexibility. The valves are ideally suited for use in conveying applications at high pressures (to 100+ psig) and high temperatures (up to 320ºF) and provide high performance in semi-dense, dense, and dilute-phase systems. O-ring-protected valve bearings and actuator-covered limit switches in several NEMA ratings deliver long-term performance. Cyclonaire Corp., York, NE 888-593-6241 www.cyclonaire.com

Dust  Collector Rotary Valve

Collector Rotary Valve

Booth 625 - The Dust Collector Series (DCS) rotary valve is suited for general use under dust collectors, cyclones, and hoppers. This valve offers eight-blade rotors, precision machining, and rugged cast iron housing for efficient operation. In a case where pressure differential exists, such as when feeding pneumatic conveying lines, the heavy-duty series rotary valve is best suited for feeding the material accordingly. These particular airlocks maintain the highest level of performance for an extended period of time. Prater-Sterling, Bolingbrook, IL 630-759-9595 www.prater-sterling.com

Abrasion- Resistant Slide Gate

Resistant Slide Gate

Booth 2071 - This gravity flow slide gate is as robust as the Vortex Aggregate Gate, but has the superior dust-tight seal of the Vortex Roller Gate. The Titan Series abrasion resistant slide gate is ideal for abrasive materials such as whole grains, coal, metal powders, or minerals up to 400°F. The heavy-duty frame is constructed with carbon steel and is available in standard sizes from 6 to 30 in. with custom square or rectangular sizes up to 72 in. and larger. Additional features are the beveled, abrasion-resistant blade and a displacement pocket on the closing end of the valve. The slide gate features “live loaded” wear compensating seals that prevent materials from escaping into the bonnet area of the gate. The gate utilizes easily accessible, hardened steel cam-adjustable rollers instead of blade guides – a feature that is critical to maintaining a positive seal. Vortex Valves North America, Salina, KS 785-825-7177 www.vortexvalves.com

Quick- Clean Rotary Valve

Clean Rotary Valve

The PQM-H quick-clean rotary valve is a new type valve with a hinged rotor. Rail-type valves have the disadvantage of allowing dust or other foreign particles to settle on the rails. By eliminating the rails, this new hinged design eliminates the problem. Specially designed hinges keep the rotor in a leveled position when extracted. The valve features easy pull-out and push-back of the rotor and shaft couplings are designed for easy engagement. The quick-clean rotary valve is constructed of stainless steel and is designed for differential pressure of 22 psi. The valve can be used for powder and pellet applications. Options include direct-drive and chain-drive, depending on customer preference, and special surface treatments are also available. The valve and all equipment and accessories are designed for complete wash–down. Various sizes are available. Pelletron Corp., Lancaster, PA 717-293-4008 www.pelletroncorp.com

Maximum-Duty Rotary Valve

Maximum-Duty Rotary Valve

The Maximum-Duty (MD) Aerolock rotary valve is engineered for heavy to severe industrial service with pressure differentials up to 20 psi and/or temperatures of 250°F. The unit is designed to withstand severe shock loads and elevated temperatures consistent with continuous 24-hour use. The MD is commonly used with some of the most challenging materials including minerals, chemicals, fillers, food ingredients, filled pellets, PVC compound, and diatomaceous earth. The MD has a ten-blade rotor that maintains a minimum three-blade labyrinth seal to minimize air leakage. The 10-blade rotor is available with flat or relieved tips in several rotor choices including open-ended, hubbed, reduced displacement, and staggered pocket. K-Tron Process Group/K-Tron Premier, Salina, KS 785-825-1611 www.ktron.com

You May Also Like