Three Reasons You Should Use Dust-Tight Valves

April 7, 2015

When it comes to selecting the right valve for your dry process application, there are many slide gates and diverter valves to choose from. Process valves are used to control the material flow in powder/bulk material handling systems (bins, hoppers, silos, downspouts, etc.) in a variety of industries such as food, grain, milling, plastics, mining, and pharmaceutical. They can be used in gravity flow or low-pressure systems, as well as negative pressure systems, each system calling out for different equipment requirements.

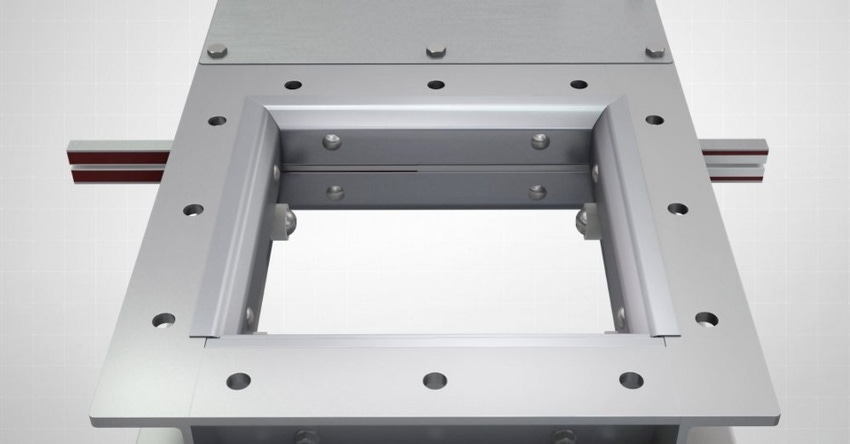

A dust-tight valve can help you mitigate these potential side effects simply by the way it is designed. This can be a challenge when using soft polymers and packing as seals. Many dust-tight valves designed today feature hard polymers (e.g. nylon, PET) as a sealing surface, because they tend to offer better wear characteristics for most applications. Constant force is applied against the valve, compressing the hard polymer into a positive dust-tight seal. It is important to pick a valve specifically designed for dry/bulk processes to control safety hazards, maintenance costs, and profitability in your plant.

1. Safety Hazards and Environmental Requirements

Dust control has been given a higher priority in many powder/bulk processes over the past few decades. That’s because fugitive emissions from a valve into the atmosphere can both be detrimental to the environment and a potential safety hazard. Processing plants have an obligation to abide environmental regulations and prevent environmental contamination and pollution. Employee and plant safety play a large role in dust control, especially when it comes to processing hazardous dust explosive substances.

Dust-tight valves can be required in processing facilities as they can drastically reduce the percentage of fugitive dust. However, when replacing a regular valve with a dust-tight valve, it is important to verify that the connections between the valve and what sits above and below are tight. For example, transition flanges need to be true and flat, with no bow, and gaskets need to be inspected and replaced if necessary. Keeping a good seal on every connection, minimizing the escape of dust from your process equipment, and inspecting and cleaning dust residues at regular intervals are all part of a robust dust control safety plan.

2. Maintenance Costs

The seal’s polymer material will eventually wear down and the valve will need to be resealed. Some manufacturers design valves with small slots in the body that let material slowly leak as an indicator that the valve needs maintenance. Choose a valve design that allows routine inspection without removing it from the production line. Side-access doors allow you to replace the old seals with new ones and start production back in minutes. In comparison, valves featuring Teflon rope require more downtime as the cartridge needs to be pulled out of the valve to remove the old rope and install a new one.

Eventually the valve will have to be taken out of service for seal replacement. That is why it is important to select the right valve and seal materials for your specific application. The correct choice of materials will extend the valve’s service life by compensating for wear and tear, and provide an excellent material seal across the valve. The ingredients being processed will also dictate your valve and seal contact materials. Cast iron, carbon steel, and aluminum are common valve materials for many powder/bulk applications, but more corrosive or abrasive materials require more durable alloy coatings, such as hard polymer, stainless steel, or carbide for the material contact points to guarantee a long service life.

3. Plant Profitability

Dust-tight valves are initially more expensive than other valves but tend to make up for the original cost difference in the long run in several ways. By keeping a tight seal, they limit the risk of material cross-contamination and increase final product quality. Their dust-tight design reduces material leakage in the plant and the atmosphere and directly affects a plant’s bottom line as it reduces concerns about product waste and pollution. Finally, dust-tight valves are easier to maintain and service. Many of them don’t require a production line shutdown longer than a few minutes at a time.

Overall, choosing dust-tight valves for your dry bulk applications will limit maintenance costs, reduce safety and environmental hazards, and reduce downtime. With so many valve options available, it is best to go with a company that has years of application experience and can help you pick the right valve for your specific powder/bulk process. Many parameters have to be taken into consideration when purchasing a valve, including the type of material being processed, if the material is abrasive or corrosive, the particle size and temperature, and if the material is being conveyed by gravity, vacuum, or pressure. Many dust-tight valves can be custom designed to meet your exact application needs and will often provide the best results.

Jason Marcotte is vice president of corporate accounts at Vortex, Salina, KS. Vortex is a manufacturer of material handling components, and specializes in process valves and loading solutions. For more information, call 888-829-7821 or visit www.vortexvalves.com.

You May Also Like