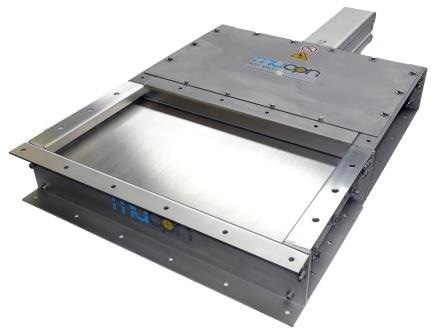

Roller Gate Valve Solves Leaking Problem

March 12, 2015

A major confectionery manufacturer in North America contacted Kemutec in the hope of finding a solution to an issue encountered with its existing roller gate valve. The manufacture process included the delivery of powder sugar onto a weigh belt feeder within their agglomeration process. The problem occurred when the handling of the very fine sugar continually leaked from its current roller gate valve.

Mucon sales and engineering personnel worked closely with the end user to understand its issues and to design a stainless steel roller gate valve that did not leak or jam. Upon completion of the roller gate valve, Mucon personnel were invited to be present at a ‘supplier acceptance test’ to witness the trial and answer any further questions that may arise.

The Mucon custom-made roller gate valve was connected to a sanitary vacuum connection and was found to work exceptionally well. In fact, it worked so well that the catch pan that was supplied to receive waste material became unnecessary.

The Mucon custom made roller gate valve comes with a progressive loading technology that rivals other valve designs and eliminates the need for any vacuum connections or catch pans to collect material or prevent product that may ingress into the valve body.

The confectionery manufacturer was so pleased with the roller gate valve and that expectations had been exceeded that they not only purchased the product that was trialed, but plan to replace the existing roller gate valves with those produced by Mucon.

For more information on Kemutec Group Inc., Bristol, PA, call 215-788-8013 or visit www.KemutecUSA.com.

For related articles, news, and equipment reviews, visit our Valves, Gates, & Airlocks Equipment Zone

You May Also Like