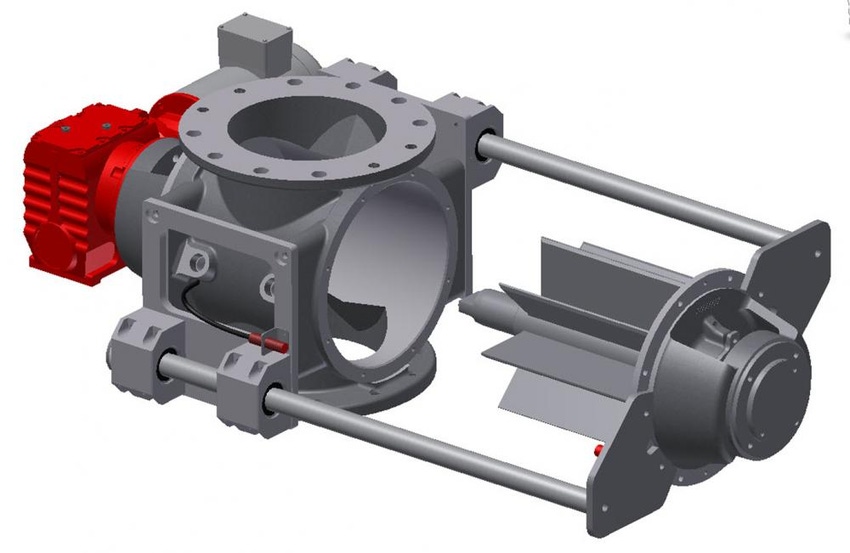

CRA De-Mountable Valve Offers Large Cubic Feet per Revolution Capacity

May 3, 2012

Mac Process has launched the CRA (Cleanable Round Airlock) valve. During the past two years, Mac Process engineers have increased the use of de-mountable-style valves in dry material pneumatic transfer systems to help customers meet challenging requirements for sanitation and inspection. With the launch of the CRA valve, Mac Process has taken an important step in a visionary Clean Design Initiative that will supply a complete line of engineered and manufactured cleanable solutions for food and pet food customers.

Offering the largest cu ft per revolution capacity — a critical improvement — the CRA can handle extremely high process rates on products. Now high-end food and pet food manufacturers can use cleanable technology in systems where high product volume demand may have prevented their use in the past. The tool-free CRA valve operation makes it easier for customers to clean their equipment after a campaign is finished to prevent bacterial growth and facilitate inspections.

“We listened to customer requirements and are bringing to market Clean Design Initiative manufactured solutions that addresses their needs. When 3A Dairy equipment isn’t required by the application, the CRA valve brings a new standard of safe food design without added cost or complexity,” said Jay Brown, president and CEO of Mac Process. “Best of all, as a single source supplier and manufacturer, we’re able to improve control over lead time and quality.”

The high-quality, high-performance CRA valve is available in four models: CRA8, CRA10, CRA12, and CRA14. Oversized rotor shafts create a naturally radiused rotor pocket, promoting product release and sustaining throughput efficiency. The valves have considerably less rotor deflection than other valves on the market. Components used in product contact areas, including the seals, are constructed of FDA-approved materials and all lubrication in and out of product zones are NSF H1 and H2 rated. Design is also available for NFPA 69 isolation valve requirements.

Mac Process, Kansas City, MO 800-821-2476 www.macprocessllc.com

You May Also Like