February 19, 2021

Joe Marinelli, president, Solids Handling Technologies Inc.

Flow aid devices are internal or external devices that are used to assist in discharging materials from a bin, hopper, or silo. Typically, they are used when flow by gravity alone will not work or when it is impractical to provide the design that is required for reliable flow. However, flow aids are sometimes used when they are unnecessary and, in fact, may actually cause flow issues.

This discussion will concentrate on the following types of flow aids:

Mechanical devices such as vibrating dischargers, vibrators, cone valves, etc.

Air operated devices such as air blasters, fluidizing cones, air sweeps, etc.

Chemical additives such as powders intended to improve a material’s flowability

Mechanical Devices-Vibrating Dischargers, Vibrators, Cone Valves

Vibrating Bin Dischargers

Mechanical flow aid devices rely on internal devices to force material to flow. Probably the most commonly used device is the vibrating bin discharger (bin activator). A vibrating discharger can accommodate hopper openings from about 3-15 ft and is intended to keep material completely live over its entire cross-sectional area. This type of device is hung from a storage bin by hangers and incorporates a rubber skirt to prevent leakage and isolate the bin from the vibrations (see photo 1). Vibration is transmitted through an outer shell and into an internal dome or cone shaped baffle, by a motor with eccentric weights. A cohesive bulk solid can be broken up and made to flow, depending on the amplitude of vibration applied.

Unfortunately, vibrating bin dischargers are notorious for creating flow problems. Although the discharger is intended to discharge material over its entire cross-sectional area, in many cases, it does not. The inner baffle is supported by four beams that create quadrants for material to flow through. Most of the time material only flows through one quadrant (usually to the right of the eccentric motor). This creates a preferential flow channel and ensures a funnel flow pattern. Most of the material remains stagnant in the silo as:

Its live capacity is severely reduced

Its structural integrity is jeopardized

It can flow uncontrolled (flush) from the outlet

It can enhance segregation

There are several considerations when using or deciding to use a vibrating bin discharger: It must discharge over its entire cross-sectional area and be operated on a regular basis, which usually requires it to be cycled on and off according to manufacturer instructions. If not, small preferential flow channels will form causing material flow in funnel flow, creating ratholes, and potentially causing structural problems. More often than not, we observe dischargers that are running constantly. They are not designed to operate this way and this approach will cause material to pack in the annulus around the inner cone. Additionally, a discharger cannot control flow rate, it is not a feeder, and as such requires a feeder to control discharge rate to your process, system, etc.

Vibrators

For years, vibration has been used to try to enhance material flow. In previous articles, we referred to a brute force approach using a sledgehammer to initiate solids flow (see photo 2). Sometimes this is the least expensive way to modify flow in a bin (and in some cases modify the shape of a bin). There are, however, vibrators available that will essentially replace the sledgehammer.

Vibrators can be mounted on the side of a bin or chute in an attempt to initiate flow. These vibrators can be air or electrically operated and come in all shapes and sizes.

There are several types of vibrators such as rotary, piston, turbine, linear, electromagnetic, eccentric, and other more specific types of vibrators. Some are designed to provide high-frequency, low-amplitude vibration to a surface. Others are required to provide high-amplitude vibrations, and still others are required to provide a “thump” like a sledgehammer. I have even seen a battering ram (basically part of a telephone pole slung from chains) used to “bang” the side of big bin in order to move material.

Cone Valves

A cone valve is comprised of an inverted cone that is positioned in the cone valve outlet. The cone is lifted and vibrated to initiate flow.

Some features of the cone valve are as follows:

It acts a gate and discharging device

It is dust tight

The vibrating cone is intended to promote flow and break bridges

If it fails, it fails safe--closed

Air Operated Devices-Air Blasters, Fluidizing Cones, Air Sweeps

Air Blasters

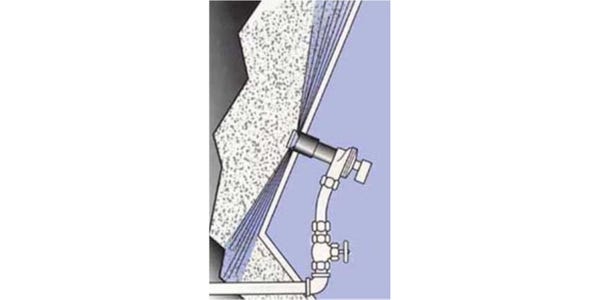

This type of flow aid device is intended to introduce a “blast” of high-pressure air, strategically aimed at a material arch, rathole, etc., in an attempt to break it up. The high-pressure air or gas is supplied by a canister that is mounted to the outside of a bin and typically refilled by plant air at 80 to 100 psi pressure (see photo 3). A quick-acting valve is opened when the unit is fired, releasing the air through a nozzle directly at the arch to break it up. The unit is then quickly refilled and ready for the next firing. Several air blasters can be placed and timed to act throughout a large hopper to maintain flow.

Some points to be aware of when using air blasters:

These devices are probably the most successful flow aid devices marketed, as they are quite efficient at breaking arches.

If material is severely caked, the initial firing will likely break it up. However, the material may only break into large chunks which you may or may not be able to handle or which subsequent firings may not break up.

Use multiple units if a single unit does not have the arch-breaking capability you need.

Be aware that the introduction of high-pressure air into a bin adds to the loads applied to that bin. Be aware especially of the localized area of the bin wall around the blaster nozzle, as reinforcement may be required.

Fluidizing Cones

Instead of letting your powder deaerate and pack in a bin, it is sometimes practical to fluidize it. Fluidization of the entire contents of a bin will prevent arching and ratholing and even provide higher discharge rates than by gravity alone. Fluidizing cones are one way to fluidize your product. Air is injected into a plenum which is mounted at the outlet and provides fluidizing air through a perforated metal dished hat or fabric. Fluidizing air can be pulsed of necessary.

Some points to remember are:

The powder must not be cohesive or else channels will form.

The material’s bulk density will be low and non-uniform.

Can you handle a fluidized material in downstream equipment?

Do you keep material fluidized at all times or do you allow it to settle out when the unit is not in use? Can it be easily re-fluidized?

The cost of fluidizing air may be prohibitive especially if your product is hygroscopic and the fluidizing air needs to be dried.

Air Sweeps

Air sweeps provide a pulse of air in a sweeping motion along a bin wall that eliminates bridging, ratholes and material build-up (see photo 4). The popup nozzle emits a high-pressure, high-volume, 360-degree burst of compressed air to lift and sweep stalled material back into the flow stream. Air sweeps cause:

Air to be discharged along the hopper wall

Undercutting of material

Localized fluidization

One important feature is that the air sweep can be mounted externally so that if you have a material hang up, you can drill a small hole and insert the sweep.

Chemical Additives

Flow aid materials and chemicals are available to add to your process to aid in material flowability. Typically, a flow aid additive is a solid or liquid that can be mixed with a difficult flowing product to produce an easier flowing product.

Fumed Silica

One of the most popular flow aid additives is silica. Silica can be added in very small quantities and is extremely effective in breaking cohesive bonds. Selecting the correct flow aid additive is just the beginning of a solution to material flow problems. Consider the following:

What affect does the addition of a chemical have on product quality?

How much additive should be used, and will it be effective in reducing cohesion?

Is it going to be too costly?

How much mixing is required for an additive to be effective?

Keep in mind that fumed silica can be difficult flowing if discharged from a dedicated hopper.

This article is a brief summary of the many flow aid approaches that can be used. Always keep in mind that gravity flow is the preferred method for handling most solids. Gravity is available, does not require maintenance, etc. However, when gravity needs help, a properly evaluated flow aid may help.

Joe Marinelli is president, Solids Handling Technologies Inc. For more information, email [email protected], call 803-802-5527, or visit solidshandlingtech.com.

You May Also Like