Storage Focus - November 2010

November 11, 2010

Bulk Forklift Container

Bulk Forklift Container

The P-433 Ship Shape bulk container features an internal, tic-tac-toe pattern design that allows product to fill recessed areas around and below the forks to lower the center of gravity vs. pallets, which require loads to be set atop the forks. The bulk container is also molded with a uniform wall thickness that is stronger yet 59% thinner than most pallet deckboards to further reduce the distance the payload sits from the forks. By bringing the center of gravity closer to the forks, the MOD P-433 container helps lift truck drivers control their payloads, reduces risk of tipping and guards against accidents. Meese Orbitron Dunne Co., Ashtabula, OH 800-829-4535 www.shipshapecontainers.com

Click to enlarge

Bulk Powder Processing SystemThis bulk powder processing system uses three 1060-cu-ft-capacity storage vessels to provide high-volume material accumulation prior to supplying the free-flowing, combustible material to downstream bulk bag filling operations. Each vessel is constructed of 304 stainless steel, measures 12 ft in diam, is internal pressure rated to 116 PSI(G), and meets ANSI and ASME standards. The integrated material storage and bulk bag filling system has a total process capacity of 17,000 lb/hr. The process area is defined to include Class I, Division 1, Groups C and D; and Class II, Division 1, Groups F and G. System-wide operations, including all automation and equipment controls, are centralized to a single, menu-driven HMI. National Bulk Equipment Inc., Holland, MI 616-399-2220 www.nbe-inc.com

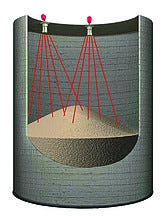

Multi-Scanner System for Large Silos

Multi-Scanner System for Large Silos

The MVL multiple scanner system integrates multiple point measurement data from two 3DLevelScanners to cover a wide surface area and provide better inventory accuracy for large vessels than any other level measurement device. Designed specifically for the challenges of large bins, the system displays a visual representation of the material surface that shows high and low points in the bin such as cone up, cone down, sidewall buildup, or bridging. Reports generated by the 3D software provide data such as volume as a percentage, in bushels, or cu ft or meters; maximum, minimum, and average levels or distances to product; weight in U.S. tons, pounds, or metric tons; and historical logs of bin measurements. BinMaster, Lincoln, NE 800-278-4241 www.binmaster.com

Click to enlarge

Top Removal Filter for Storage SilosThe Modu-Kleen Series 725 top removal bin vent filter allows vented discharge air to be exhausted but prevents any outside atmospheric air from entering the storage silo or surge bin. This is ideal for venting storage bins and silos which contain hygroscopic materials that absorb moisture from the atmosphere. Materials such as granulated sugar and salt remain lump free and are handled much easier. The unit fully meets the new OSHA requirements for confined space requirements. Each filter is independent and can be easily removed without having to enter any kind of filter housing, making maintenance and troubleshooting quick and easy. This also makes maintenance far safer when trying to filter hazardous or toxic materials. An added benefit is its modular nature. If additional filter area is required, it can be easily and economically added. Pressure differential and automatic self-cleaning controls are standard. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

Dry Bulk Storage Tanks

Dry Bulk Storage Tanks

The BulkTec line is designed specifically for the storage of dry bulk materials. These tanks can store dry bulk materials such as food, chemicals, aggregates, minerals, and plastics in capacities up to 2.0M cu ft. Products include factory-welded silos, traditional bolted chimed panel designs, bolted notched panel designs, and new flat panel designs. The factory-controlled OptiBond coating process yields high coating performance, abrasion resistance, smooth material flow, and durable, long-lasting life. Dry bulk storage systems can be custom engineered to specific application needs and all industry standards. Because each panel is factory coated, the bolted tanks are constructed on-site up to three times faster than field-welded tanks. Columbian TecTank, Parsons, KS 620-421-0200 www.columbiantectank.com

You May Also Like