Professional Silo Cleaning Saves Lives

April 27, 2018

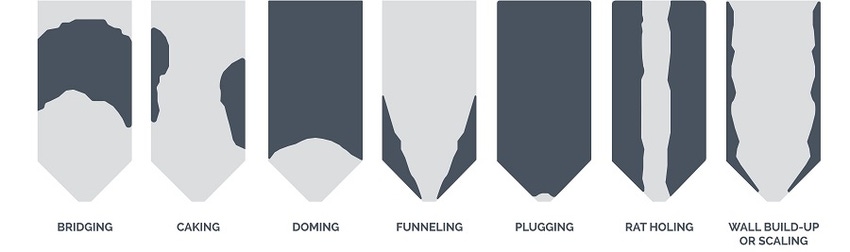

No matter the design or the materials stored, silos are susceptible to material flow issues caused by blockages. There are numerous blockage types possible in storage silos, including bridging, caking, doming, funneling, plugging, ratholing, and wall buildup or scaling (as shown). Silo blockage type may also be some combination of these or of an unknown nature.

Material flow that is unimpeded by blockages is essential for smooth operations and the continued functionality of your silo. Blockages not only lead to a reduced storage capacity and disrupted or slowed operations, they also promote bad flow characteristics. When material flow is off, delamination, exterior concrete cracking, and structural failure can result.

You can help reduce the likelihood of material buildup through a number of ways. Depending on how easily stored material compacts or hydrates, your silo may need to be completely emptied on a regular schedule as often as once a month or as little as every year.

Cement Silos

To prevent stored cement from setting inside the silo, the structure must be completely watertight. Even pinhole leaks in silo roofs and walls damage your stored materials and can result in blockages and material flow issues. Ambient humidity levels can also cause some materials to set. If you do aerate stored materials, it is important to use air dryer systems to help lower the ambient humidity level in the silo. You should also avoid over aerating stored materials. Excess aeration can pump unneeded moist air into the silo which may lead to hydration of the cement.

Essential maintenance includes exterior waterproof coating(s) and keeping your air pad and air stones in good operating condition. Completely emptying your silo frequently is also important as it helps prevent compaction of stored materials.

Fly Ash Silos

It is important to keep the fly ash cool as it is loaded into the silo. Make sure your ash does not include unburnt carbon material as this can lead to material buildup along the silo walls. Chemicals from pollution control chemicals can cause your ash to become cementitious, or sticky. Coal from the Wyoming Powder River Basin is also inherently cementitious in nature. Cementitious material leads to asymmetric flow. Silos that exhibit asymmetric flow are likely to develop blockage issues that require professional cleaning.

Professional Cleaning

It is extremely important to get your silo cleaned professionally if you have material buildup or other issues. Silo cleaning using your own, untrained labor force is highly dangerous and can lead to silo damage and accidental death. Two untrained workers in Wisconsin recently lost their lives after attempting to clean a blocked silo.

When workers enter a silo in an attempt to clean it, falling material can damage silo walls, cones, and discharges leading to catastrophic structural failure. This endangers those inside the silo as well as surrounding workers who can be crushed or buried by falling materials. Surrounding equipment and structures can also be damaged by structural failure of the silo.

Professional silo cleaning companies typically use a remote, dry cleaning system to remove material buildup without compromising worker safety through entry into the silo. In cases of stubborn buildup, however, professionals also use supplemental cleaning systems, such as Cardox shells, to blast away problem areas.

When looking for a professional silo cleaning company, it is important to review their reputation as well as the cleaning system used. Whip systems tend to be the most expensive. As the slower system on the market, they result in increased downtime and a longer total time on site. Pneumatic systems provide additional cleaning power and therefore reduce the total downtime.

The most powerful system available in the U.S. is an enhanced compressed air system that removes the most material buildup in the least amount of time making it the most efficient and cost-effective system available.

No matter the cost, however, professional silo cleaning helps save lives.

Dennis Blauser is the CEO of Marietta Group, which houses Marietta Silos and Marietta Inspection Services and USA Silo Service. For more insights, visit www.askmrsilo.com/resources.

For related articles, news, and equipment reviews, visit our Storage Equipment Zone

Click here for a List of Storage Equipment Manufacturers

You May Also Like