AirSweep System Prevents Material Build-Up, Cuts Turnaround, Cleaning Time

AirSweep can be used for both material flow and vessel cleaning

September 15, 2021

The AirSweep system has many uses and applications. Aside from promoting on-demand flow, it can keep materials from adhering to the inside surfaces of process equipment to help ensure batch uniformity, and also clean and flush vessels between production runs. This reduces the time needed for final, manual cleaning, and for some industries it can help protect product quality and safety.

Problem

An infant formula manufacturer produces several varieties--including lactose-free powdered formula mixes--in the same processing and packaging lines. It relies on a labor-intensive, multi-step process of flushing and manual cleaning because even trace amounts of cross-contamination may compromise the next batch and affect its consumers. The manufacturer couldn’t take risks with a baby’s health.

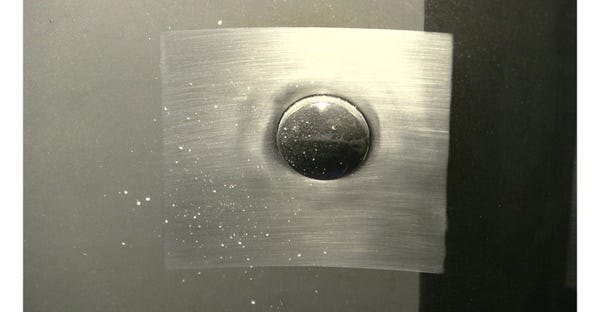

Formula blends use ingredients containing high fat, sugars, and proteins that tend to cling to process vessel walls and inner surfaces. Some vitamin and mineral compounds also segregate out of the blends, causing out-of-spec formulations in the final product. This results in some batches of finished product to be scrapped or re-blended.

The mixture would cling to the vessel walls, posing the risk of cross-contamination and spoilage.

Solution

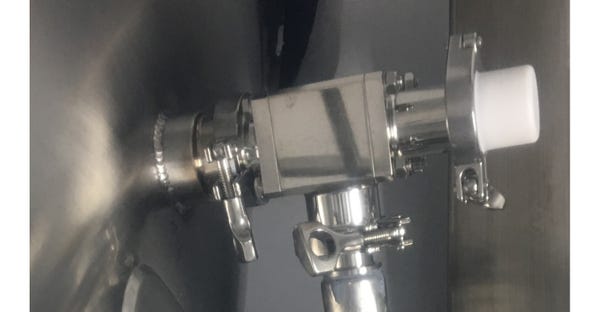

The manufacturer installed AirSweep USDA 135 and 185 and straight shooters in its blenders, vacuum receivers, sifters, and packaging line vessels. By pulsing the AirSweep units during and after the batch runs, the manufacturer found that the powerful air pulses swept the vessel walls and inner surfaces of residual powder buildup. This made a significant, positive impact on blend uniformity and dramatically lessened the labor and time needed to clean after the batch runs were complete. This allowed the manufacturer to add batch runs and increase production output.

The AirSweep USDA models can be removed without hand tools for quick and easy cleaning. The nozzle seals shut after each pulse for zero material feedback.

Results

AirSweep helped prevent material build-up during, and after, the process—proving its versatility and value.

“Beyond reliably producing a consistent product, they’ve also cut their turnaround and cleaning time significantly—saving tons of money,” said Paul Rose, AirSweep’s sales director.

After the initial pilot test in one facility in 2016, the company has since added AirSweeps to the other process lines in that plant, and in four other plants worldwide, and are currently adding the system to other plants. “We went from 40 hours to 10 hours in cleanup time,” said the company’s associate director for process technology application and productivity.

For more information, contact Control Concepts Inc. (Brooklyn, CT) at 860-928-6551 or visit controlconceptsusa.com.

About the Author(s)

You May Also Like