Application of Jet Milling Technology to Improve Process Efficiency

The most important aspect to determining what is possible is process optimization through material testing.

March 31, 2023

Kyle Shanley, process engineer, NETZSCH Premier Technologies LLC

In the world of particle size reduction, jet milling has always been an ideal means of achieving fine particles. Jet mills are named from their source of grinding energy: compressed gas expanded through a nozzle or nozzles to create a high velocity gas jet. While there have been many variations of equipment designs using this base technology, modern fluidized bed jet mills with internal classification show many benefits above other types of jet mills.

They use opposed jets within a bed of material and a built-in dynamic air classifier for control of PSD (particle size distribution) top cut. This configuration gives high-velocity particle-to-particle collisions within the fluidized bed, while limiting high-velocity contact with the internal surfaces of the mill. This makes these mills ideal for handling materials of a wide variety of hardness and abrasiveness without excessive machine wear and contamination to the material, ideal for materials requiring high purity or clean color. The velocities at the jets can also be the highest seen in any milling technology, allowing them to grind materials to the finest PSDs. Also, because they are using a gas as the means for grinding, it is very easy to control temperature and essentially zero temperature rise inside the mill can be achieved.

Jet mills are easily the most flexible and versatile of all milling technology, but often find themselves locked out of certain applications and industries. A traditional jet milling process is often operating with grinding nozzle pressure of around 7 barg at 250˚C. An air compressor must use notable amounts of energy to achieve compressed air at this pressure and temperature. Even more energy is used if the air must be oil-free and dry, which is common in jet milling processes. This leaves the most versatile and beneficial form of particle size reduction out of many processes because of high capital investment costs or high energy costs. This has led to many preconceptions that jet milling is only reserved for high value materials, materials requiring the finest PSDs, or materials requiring high energy to be milled. The truth is however, that a jet mill can be operated in different ways and can be ideal for many applications that historically have turned away from the technology. Here we will examine the possibilities of creating an efficient jet milling process fitting a wide range of applications, with the focus on the fluidized bed jet mill.

Hot Gas and Reduced Pressure Jet Milling

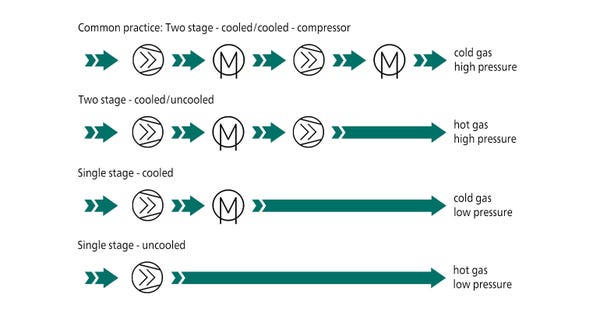

If we want to find ways to improve the energy efficiency and cost of a jet milling process, we must look to the main source of the energy consumption: the air compressor. It is well known in the industry that compressing air is not inherently an efficient process, with many high-pressure compressors in the 40–60% efficiency range. To address this, we look to a standard two-stage, oil-free air compressor (Figure 1). To reach the desired pressure and temperature, ambient air is first compressed up to about 4 barg where it heats up to around 2,000˚C. This air is then cooled and compressed again, where it reaches up to 8.0 barg and is again heated to around 1,600˚C (exact values may vary). If ambient temperature grinding air is needed, this air must now be cooled again, leaving us with four steps to reach high-pressure, ambient temperature compressed air. So, what if we begin to remove some of these steps from the air compressor?

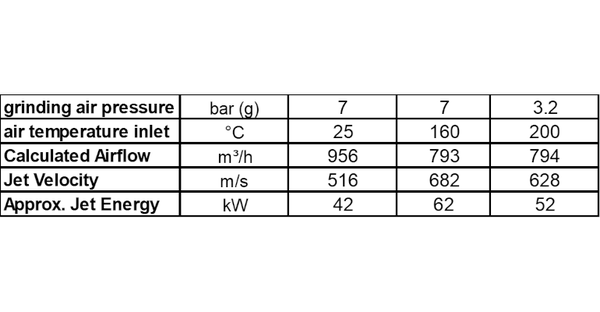

We can consider two main scenarios: Removal of the final cooling stage, giving us up to 8 barg and 1,600˚C air, or removal of both cooling stages and the second compression stage, leaving us up to 4 barg and 2,000˚C. But we must understand how this will affect the operation of our jet mills? Below you can see some values that could be achieved on a common design fluidized bed jet mill.

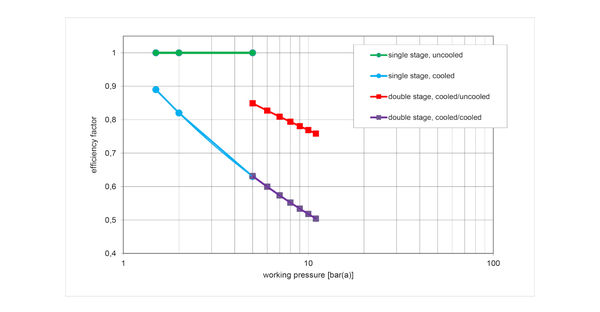

What we see here is that air temperature has a direct effect on the air velocity after the nozzles and thus, the grinding energy. Now we have not only removed steps from the air compression process, but also improved the energy input to our grinding process with less gas volume. This is drastically seen when we consider 3.2 barg and 200o C grinding gas, sometimes known as “E-Jet” process, where we will see higher velocities and energy input as compared to 7.0 barg and 25˚C grinding gas. So here we have the benefit to the jet mill operation, but how does this effect the air compressor operation? Below you can see some common air compressor efficiencies for different air compressor configurations.

It can be seen as we remove cooling and compression stages, we improve the efficiency of the compressor, with a single stage, non-cooled compressor theoretically reaching 100%. This has the additional benefit of reducing the capitol cost of the compressor each time a step is removed, as well as savings in any cooling mediums used in the cooling steps.

There are of course some modifications required to the jet mills themselves to handle high-temperature gas and perform ideally at these temperatures and pressures. Jet mills running with hot gas can use an oil lubricated bearing design, which has both better life and reliability over greased bearings at these higher temperatures. But overall--even with some modifications to the equipment--cost and energy reduction will always be seen.

Low-Pressure Jet Milling

We have now seen one opportunity to improve jet milling efficiency by means of compressor efficiency, but can this be taken further? It has been determined there are applications where we can go even lower in grinding nozzle pressure. There is a range of applications, usually materials needing de-agglomeration or very low energy to grind, which have been historically processed using some type of mechanical impact milling (air classifier mills, hammer mills, pin mills, etc.). Most grinding which uses mechanical impact uses speeds between 100 and 250 m/sec to accelerate particles. What if we look at grinding nozzle pressure on a jet mill less than 1 barg, or even as low as 0.3 barg? In this range, we can now see jet velocities between 150 and 300 m/sec, meaning the jet mill nozzle velocity is similar to that seen with mechanical milling processes. But simply matching the velocity and energy input does not necessarily mean the overall processes are comparable when looking at efficiency. We must now look at comparative data, and what can be done about efficiency when jet milling with these low pressures.

One solution considered is to remove the air compressor entirely, and replace it with a positive displacement blower, typically a rotary piston blower. This allows us to approach 100% efficiency in generating air pressure up to 1 barg, lowers the capitol cost, and lowers the power consumption compared to a screw type air compressor. We must also look at comparative tests between mechanical mills and jet mills. The focus for these comparisons was specifically with air classifier mills, where energy input comes via beaters on a rotor, and particle size is controlled by a built-in dynamic air classifier. What can be seen in some applications, is higher production rates from the low-pressure jet mill at the same final material quality. This will of course vary by material and application, but many have been found through various testing. When we now look at the complete process, we can see overall improvement in specific grinding energy and efficiency. Similar results can be found with grinding nozzles pressures between 1 and 3 barg. In these cases, we must return to an air compressor, but we are able to use single stage compressors and use much lower installed motor power to achieve these lower pressures.

Now we have the benefits of operating and maintaining a jet mill, especially when comparing to mechanical mills, which will always have more wear parts and require more maintenance long term, and still have an energy and cost-efficient process. These benefits become even more apparent when we talk about hard and abrasive materials, or processes which require high purity and limited contamination. There are many cost advantages and less limitations to implementing wear protection or iron free processing in a jet mill when compared to mechanical mills, or more specifically, air classifier mills. It must be noted that most standard jet mill designs will not operate optimally in these low grinding nozzles pressures, especially below 1 barg, and some modifications must be made to the base machine. Research has been done in this area within the industry and special executions of fluidized bed jet mills ideal for these low pressures are on the market.

Steam Jet Milling

We have now looked at two different ways jet mill operation can be changed to fit more applications, but in both cases we looked primarily at air jet milling (could also apply to inert gases). There is however another medium used in jet milling that can be explored, and that is steam. Here we will look at how steam jet milling can affect process efficiency, again with specific regard to a fluidized bed jet mill design. This design of steam jet mill utilizing a fluidized bed and built in dynamic air classification, is somewhat unique to the industry and does play an important part in the possibilities using steam.

Steam jet milling is often considered because of the need for high-energy input. Super-heated steam is often generated up to 40 barg and 350˚C, in some cases even higher. These temperatures and pressures allow for very high grinding nozzle velocities, up to 2-3 times the speed of sound in some cases. Steam also has a lower viscosity when compared to ambient air, allowing dynamic air classification to classify even finer particles. These two points mean a very common application for steam jet milling is super fine grinding, but perhaps there is more to be done with steam?

As we have learned from air jet milling, the process of compressing air is relatively inefficient at higher pressures, so where does steam compare in generation efficiency? If we consider here 40 barg steam at 350˚C, it can be generated at up to 90% efficiency, much higher than standard high-pressure air compressors. So now we must look at how this directly compares to air jet milling.

In many cases, it can be observed that when a material is milled to the same PSD on the same physical size and design of air jet mill and steam jet mill, higher throughput is seen with the steam jet mill. Of course we are putting much more energy into the material using steam, so this is to be expected, but there is some opportunity here for process improvement. While we may see throughput increase, we will almost always have comparable specific grinding energy, so on the surface it may not seem the process efficiency has been affected. However, when we now consider the power and efficiency of steam generation versus compressed air generation, we often see improved energy consumption over the complete system.

Steam jet mills and steam generators do often come with higher capital investment, but for applications where high production is important without completely disregarding energy consumption, there is a lot of potential using steam. Like other jet milling process, some process optimization through testing can help lead to the ideal steam pressures and temperatures needed for specific grinding energy improvement. Steam at high pressure and temperature also comes with some unique properties, able to remove moisture from many materials, even able to dry slurries of material suspensions within certain conditions. In these cases, we are also using fluidized bed jet mill designs for our steam jet mills, so we can still utilize this designs advantages for wear protection and contamination free milling, meaning a wide range of applications can use this technology.

Summary

While the many different forms of fine grinding will always be needed for a variety of applications, we have learned that the jet milling process can be a great fit for many industries and applications. We must always still consider limitations of different processes, e.g. materials with temperature limitations cannot gain the benefits of steam or hot gas jet milling. We also know that there are materials which require the different types of impact and shear forces that might not always be seen in a jet mill. However, through new innovations and exploration of jet mill operation, even applications historically thought to be out of jet milling range, may be the right fit.

The most important aspect to determining what is possible is process optimization through material testing. It is important to understand how varying temperatures and energy inputs effect the grinding process of a specific material. Using industry experience and available test laboratories, specific grinding energy optimization can always be obtained, pointing us to the best jet mill process. Ideally, test laboratories with multiple forms of fine grinding can be utilized, allowing not only the optimization of jet milling processes, but comparison to other equipment to truly find the optimal process. The most important take away from the presented information, and the extensive research done in this industry, is that jet milling should not immediately be thought of as a costly and energy intensive process, and every day we are finding new ways to improve processes through exploration of jet milling.

Kyle Shanley is a process engineer at NETZSCH Premier Technologies LLC with more than a decade of experience in dry processing. He oversees customer lab tests at the customer test laboratories in Exton, PA. He is responsible for high-level process design and the scale-up and process optimization of dry equipment. He also oversees the development and installation of new equipment in the test labs. For more information, visit www.netzsch.com/en.

You May Also Like