Screening, Classifying, & Separation

June 7, 2011

Circular Unitized Gyratory Screen

Circular Unitized Gyratory Screen

The Vibroscreen is a circular unitized gyratory screen with three-component multi-plane mechanical vibration. The motion is through a motor with a double extended shaft, fitted at both ends with eccentric weights. The whole drive assembly is mounted on a circular base by rugged springs that allow the unit to vibrate freely, and at the same time, the springs prevent transmitted vibration from reaching the floor area on which the machine stands. Screens can be mounted one on top of the other within the screening assembly. (Pennwalt LTD) Heinkel USA, Swedesboro, NJ 856-467-3399 www.heinkelusa.com

High-Capacity Vibratory Classifier

High-Capacity Vibratory Classifier

A new Vibroscreen high-capacity, two-deck classifier separates up to 70 tn/hr of bulk solids into three fractions. Measuring 100 in. in diameter, it classifies bulk chemicals, minerals, plastics, foods, dairy products, pharmaceuticals, and other materials ranging from dry bulk solids to solids-laden slurries. Quick-disconnect clamps between each screen frame provide rapid interior access for inspection, screen changes, and wash down. An optional Air-Lift device pneumatically raises any of the screen frames, enabling one operator to rapidly perform what was previously a two-person task. Kason Corp., Millburn, NJ 973-467-8140 www.kason.com

Pneumatic In-Line Sifter

Pneumatic In-Line Sifter

The QA36 pneumatic in-line sifter was designed with a high net screening area and is an ideal HACCP solution for operations with moderate to high production volumes. The capacity is over 500 lb/min on soft wheat flour and over 650 lb/min on hard wheat flour using a 30 mesh screen. The QA36 is manufactured with a high level of sanitation in mind, as well as ease of maintenance using lightweight components, and form fitting, snap-on neoprene gaskets. The sifter utilizes the gentle gyratory sifting motion and is designed to be directly inserted into a vacuum or dilute-phase pressure pneumatic conveying system. Great Western Manufacturing Company, Inc., Leavenworth, KS 913-682-2291 www.gwmfg.com

High-Volume Screener

High-Volume Screener

Booth 542 - The Megatex XD screener delivers accurate screening performance in a compact footprint. It is ideal for a wide range of screening processes, including agriculture, plastics, and chemical applications. An elliptical linear motion provides efficient screening performance with less downtime and lower energy consumption. The screener provides 25%–50% greater capacity per square foot of screen cloth. The elliptical-linear motion—generated by an external drive cartridge—separates from ¼ in. to 100 mesh. The Megatex XD requires minimal maintenance. Single screen deck changes take no more than 10 minutes, and all screen decks can be changed in just two hours. Powered by a single 15- or 20-hp motor, the screener also minimizes energy. Rotex Global LLC., Cincinnati, OH 800-453-2321 www.rotex.com

Grate Magnets

Grate Magnets

Booth 557 - The EZ-Clean drawer magnet eliminates the time-consuming and tedious process of manually removing collected metal. Cleaning is now easily accomplished by pulling the magnetic drawer of grate tubes through stationary outbound wiper seals. Collected metal falls into a catch pan located outside of the product stream for disposal. These magnetic grates can be finished to customer requirements and retrofitted to existing bag dump stations. The food-grade, Class 1 rare earth magnetic grate removes fines from blended ingredients used in the food industry. The grate magnet is designed to sit inside an existing hopper with the angles on the four corners supporting the grate as well as to allow the product to slide towards the magnetic tubes, eliminating the chance that product gets past the magnet. The diverter in the center helps divert the product towards the tubes and adds strength to the structure. Industrial Magnetics Inc., Boyne City, MI 888-582-0821 www.magnetics.com

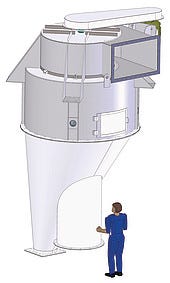

Vertical Shaft Classifier

Vertical Shaft Classifier

The model MCS-800 classifier has a nominal air flow of 48,000 cfm and can be designed to suit a variety of material applications and product rates. Airflow and particle behavior are predicted using state-of-the-art finite element-based flow modeling software and empirically verified through on-site laboratory and pilot plant testing. The feed material can be introduced pre-dispersed in an airstream or mechanically fed into the classifier. The airstream can be recycled to the classifier in closed-circuit operation or filtered and discharged to atmosphere in open-circuit operation. The cut point of the fine product can be precisely controlled by varying the rotational speed of the classifier blades. RSG Inc., Sylacauga, AL 256-378-3836 www.airclassify.com

Centrifugal Sifter

Centrifugal Sifter

Booth 625 - Engineered to meet high-capacity sifting for bulk load-in/load out and larger process applications, the Rota-Sieve is cost-efficient in the handling of a wide variety of powder, granules, agglomerates, and other free-flowing materials. The combination of high-centrifugal force and blade spreading action reduces binding problems, even when handling materials that tend to flake or agglomerate due to fat and moisture content. The sifter not only can be used for sifting, scalping, and classifying, but may also remove foreign material, such as plastic and string. Prater-Sterling, Bolingbrook, IL 630-759-9595 www.prater-sterling.com

Ultrasonic Upgrade Systems for Screeners

Ultrasonic Upgrade Systems for Screeners

HK powder screening and separating equipment combines mechanical vibration with ultrasonic screening for greatly reduced or eliminated screen blinding for fine particle applications. HK ultrasonic conversion systems are designed to easily upgrade round gyratory screeners to full ultrasonic screener functionality in minutes. The efficient vacillating motion that these units add to traditional screeners in the micrometer range decreases friction between the powders being screened and screen surface to significantly increase throughput. Plus, these systems feature 100 percent screen usage, rescreenable screen frames, screening for 8- and 12-in. sieve frames to 10 micron, and screening for sieve frames larger than 12 in. to 20 micron. Conversion units are available in a variety of screen sizes for any screener manufacturer, including laboratory models in 8- and 12-in. diam and larger models in 18-, 24-, 30-, 36-, 40-, and 48-in. diam. Cleveland Vibrator Co., Cleveland, OH 800-221-3298 www.clevelandvibrator.com

Manual Clean Drawer Magnets

Manual Clean Drawer Magnets

Booth 339 - Engineered to remove medium and fine ferrous contaminants from dry, free-flowing products under gravity flow, these drawer magnets protect processing machinery and improve product purity. Multiple staggered rows provide maximum contact area for product flow. As product flows through the stainless steel housing, it cascades over the staggered rows of magnetic tubes. Ferrous contaminants are pulled to the surface of the magnets where they move to the underside of the tube to prevent washoff. EZ Clean and POW-R Clean options are also available for simplified cleaning. Puritan Magnetics, Oxford, MI 800-787-3624 www.puritanmagnetics.com

Magnetic Separators

Magnetic Separators

Booth 439 - The ProGrade line of magnetic separators includes standard magnetic plates, grates, traps, and tubes. These professional grade magnets are available at three different degrees of magnetic strength, enabling professionals in diverse industries to choose the ideal level of protection for their specific application. ProGrade Ceramic series, ProGrade Rare Earth series, and ProGrade Xtreme series are available. ProGrade Ceramic series target the removal of medium to large ferrous contamination. These products offer basic protection from tramp metals damaging downstream equipment. The ProGrade Rare Earth series targets small, fine, and weakly magnetic ferrous contamination. Assemblies are designed with precise attention to welds and finish, and feature stainless steel construction and high power magnets. The ProGrade Xtreme series is designed for food and pharmaceutical-grade assemblies for ferrous contamination removal. Eriez, Erie, PA 888-300-3743 www.eriez.com

Round Separator

Round Separator

Booth 335 - The MX separator has design features to increase safety, provide a stronger construction, and allow for a more sanitary process. The totally enclosed weight guard prevents “reach-in” injuries, complying with CE Standards. Making use of the appropriate motor, the MX also complies with ATEX Standards. Angled support springs minimize aggressive vibration that typically occurs during shutdown of the machine. The rugged construction of the MX utilizes conical construction rather than flat plates, creating a more rigid geometric structure. The open-base construction allows for cleaning underneath the unit, preventing dirt and product build-up. Additionally, the MX base design eliminates all gussets and external crevices where product can become trapped, while allowing for total external polishing of the machine. Sweco, Florence, KY 800-807-9326 www.sweco.com

Rectangular Screeners

Rectangular Screeners

Booth 631 - Virto screeners are based on a multi-frequency adapter that converts vibratory technology to impart high amplitudes/high energy directly to the screen surface. This energy pattern prevents blinding and stratifies the material across the screen surface to provide separation performance improvement. The ScreenX 2.3x1 and ScreenX 2.8x1.4 rectangular machines excel on minerals, building materials, mining, and chemical applications. Equipment usually operates at a rate of three to 12 times greater than standard vibratory screeners. Efficiencies of 95% and greater are achieved in a single pass. Virto/Elcan Industries, Mamaroneck, NY 800-283-5226 www.virto-elcan.com

Horizontal Screener

Horizontal Screener

Booth 457 - The Texas Shaker Colt is equipped with two standard 1800-RPM electric motors that drive independent full-width unbalanced rotors through conventional V-belt drives to generate a straight-line motion with ¾-in. stroke. The separation of the motors from the unbalanced rotors allows larger bearings with long service life and promotes effective cleaning ball action to prevent blinding. The long stroke, slow-speed, zero-pitch action provides more efficient screening in the finer mesh ranges. Available screen sizes range from 3x6 ft to 5x10 ft, in one, two, or three decks. Triple/S Dynamics, Dallas, TX 214-828-8657 www.sssdynamics.com

Large Bag Metal Detector

Large Bag Metal Detector

Booth 1231 - Utilizing a specialized coil structure, the Phantom large bag metal detector achieves high performance with large product sizes: 2.0 mm 316 stainless steel detection in 50-100-lb bags. The system performs to a high specification in harsh production conditions including electrical noise and vibration. The Phantom technology enables an RF noise reduction modification that reduces the detector’s susceptibility to interference. Known as the “Big Bag King”, the system is offered in conjunction with an integrated Vector conveyor system for an optimized all-in-one detection solution. Fortress Technology Inc., Toronto, ON, Canada 888-220-8737 www.fortresstechnology.com

Centrifugal Sifter

Centrifugal Sifter

Booth 657 - The Kek centrifugal sifter offers high-speed and efficient processing of powders, granules, and slurries. Featuring a fully cantilever shaft, the unit benefits from easy access and rapid screen changes, in most cases under 30 seconds. This design facilitates easy cleaning and provides high standards in hygiene. It also features virtually tool-free maintenance resulting in maximum output and uptime. The sifter is available for gravity and full inline pneumatic conveying applications with output ranges from a few pounds to more than 100,000 lb/hr. The unit provides size classification for a variety of applications including: de-agglomeration, bulk conditioning, classification, scalping, in-line sifting, policing raw material, de-dusting, de-watering, and reclaiming damaged product. It is compact, dust tight, vibration free, and virtually silent. Kemutec, Bristol, PA 215-788-8013 www.KemutecUSA.com

Stainless Steel Magnetic Separator

Stainless Steel Magnetic Separator

Booth 324 - This stainless steel easy-clean magnetic separator eliminates the problem of ferrous contamination and improves product quality. The new magnet can be used on the range of compact sieves, including the high-containment Compact Airlock Sieve, as well as the Finex 22 model. The magnet instantly attracts ferrous particles and securely holds them onto its bars, keeping unwanted material out of the final product. Constructed from 316L grade stainless steel, and available in a brush or mirror polished finish, the magnetic separator has been strenuously tested at Russell’s ISO:9001 accredited facilities to ensure reliability. It is available as a standard ferrite model, made of material achieving 4500 Gauss, or in more powerful rare earth options made of neodymium iron boron reaching up to 14,500 Gauss. Russell Finex Inc., Pineville, NC 800-849-9808 www.russellfinexusa.com

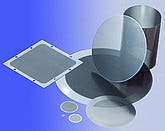

Stainless Steel Screens

Stainless Steel Screens

Fine MicroEtch stainless steel screens are manufactured using photoetching technology. Photoetching enables designers to specify a straight or tapered hole. Hole sizes range from .003 in. and up. Applications are hydraulic valve screens, fuel filters, laser light filters, extruding screens, plus particle separation and sizing. A standard line of screens with holes in a 60° or 90° pattern are available with maximum guaranteed perforated area of 18 x 21 in. Tech-Etch Inc., Plymouth, MA 508-747-0300 www.tech-etch.com

Inverting Filter Centrifuge

Inverting Filter Centrifuge

The HF model centrifuge incorporates inverting filter technology, thin cake processing technology, and PAC direct contact drying of the material all in one machine for separation/filtration. With these combinations of technologies, it is possible to dry product inside of the centrifuge, thereby reducing time or eliminating downstream drying equipment. Other advantages include no residual heel remains on the filter cloth, repeatable batch quality, and full flexible process recipe management. The HF machine will deliver high production capacities and can handle difficult filtering materials. Heinkel USA, Swedesboro, NJ 856-467-3399 www.heinkelusa.com

You May Also Like