Screeners

October 11, 2011

Vertical Spout Magnet

Vertical Spout Magnet

Engineered to remove fine to large ferrous contaminants from high-volume, gravity-fed product streams, these vertical spout magnets are suited for products that would bridge or choke in a magnetic tube type separator. Ferrous contaminants are easily removed from products that are moist, lumpy, granular, or in powder form. Two powerful opposing magnets mounted to the outside of the housing draw tramp metal out of the product stream. A center diverter on the housing inlet helps direct product towards the magnets. A single trap face design eliminates the possibility of the captured tramp metal being washed off back into the product stream. The magnets retract from the housing taking the tramp metal out of the product flow area. Puritan Magnetics Inc., Oxford, MI 248-628-3808 www.puritanmagnetics.com

Metal DetectorThe Stealth metal detector is the latest addition to the Phantom series. The design offers full backwards compatibility, ensuring spare parts and upgrades are readily available for existing systems. Features of the new unit include powerful digital signal processing (DSP) technology that provides high-speed precision detection, while ultra-sensitivity levels detect the smallest metal contaminants. Quality Assurance testing on samples can be initiated on demand or by time interval, and the software filtering system enhances performance while minimizing false rejects. Access to QA reports via Fortress Contact software and easy metal detector updates are enabled by the USB connector. Fortress Technology Inc., Toronto, ON, Canada 888-220-8737 www.fortresstechnology.com

Metal DetectorThe Stealth metal detector is the latest addition to the Phantom series. The design offers full backwards compatibility, ensuring spare parts and upgrades are readily available for existing systems. Features of the new unit include powerful digital signal processing (DSP) technology that provides high-speed precision detection, while ultra-sensitivity levels detect the smallest metal contaminants. Quality Assurance testing on samples can be initiated on demand or by time interval, and the software filtering system enhances performance while minimizing false rejects. Access to QA reports via Fortress Contact software and easy metal detector updates are enabled by the USB connector. Fortress Technology Inc., Toronto, ON, Canada 888-220-8737 www.fortresstechnology.com

Vibratory Check-Screener Enhancement

Vibratory Check-Screener Enhancement

The Vibrastop is the latest in starter technology to provide rapid startup and shutdown, eliminating excessive sieve movement. Vibration is transmitted into industrial screening machines by means of a vibratory electric motor. As with most motors, there is a short period of time before the operating speed is reached from initial startup and an even longer time period during shutdown until the motor finally comes to rest. These two phases cause the motor to pass through its resonant frequency and as a result, up to six times more vibration can be transmitted into the sieve when compared to what is normally transmitted during normal sieve operation. This resonance causes excessive noise but more problematic movement in the sieve. Russell Finex Inc., Pineville, NC 800-849-9808 www.russellfinex.com

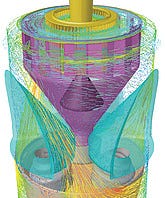

Hybrid Turbine Classifier

Hybrid Turbine Classifier

The Raymond hybrid turbine classifier’s patented design enhances system and process performance. The Raymond bowl mill equipped with this classifier produces particle size distributions compatible with improved flame characteristics while reducing emissions and minimizing unburned carbon. The particle size distribution facilitates combustion of fuel possessing a coarser average particle size without sacrificing system performance or compromising process capability. The classifier is available for all types of Raymond bowl mills or other manufacturers’ pulverizers. Alstom Power Inc., Raymond Operations, Warrenville, IL 630-393-1000 www.raymondpulverizers.com

Versatile Drawer Magnets

Versatile Drawer Magnets

HF series drawer magnets are equipped with powerful magnetic cartridges to handle a wide range of separation tasks in mechanical or gravity flow applications. They can be configured with two or more cartridge trays arranged so that the cartridges are staggered to increase contact with the product stream. Material moves in a zigzag pattern from one cartridge tray to the next for exceptionally thorough cleaning. They are available in utility, powder, food, and sanitary construction grades with three cleaning options and stainless steel housings. Custom transitions are supplied to match your spouting. Magnets are CE Certified. Bunting Magnetics, Newton, KS 800-835-2526 www.buntingmagnetics.com

Stainless Steel Screens

Stainless Steel Screens

Fine MicroEtch screens from stainless steel and polyimide film (Kapton) are manufactured using photoetching technology. Photoetching enables designers to specify a straight or tapered hole. Hole sizes range from .003 in. and up. Applications are hydraulic valve screens, fuel filters, food processing, pulp separation, fiber extruding, plus particle separation and sizing. Standard line of screens with holes in a 60- or 90-degree pattern are available with maximum guaranteed perforated area of 18x21 in. Tech-Etch Inc., Plymouth, MA 508-747-0300 www.tech-etch.com

Magnetic Pneumatic Line Housing

Magnetic Pneumatic Line Housing

The custom cart-mounted magnetic pneumatic line housing’s portable design allows it to be utilized in multiple locations such as loading/unloading from railcar, truck, or silo storage systems for dry/bulk pneumatic transfer applications. The unit’s staggered magnetic tube configuration ensures that all product flowing through the housing makes repeated contact with the magnets. The resulting capture rate of ferrous and weakly magnetic stainless contaminants far exceeds any other magnetic separator available for this type of application. A removable screen has also been incorporated to capture non-magnetic objects, making this unit an exceptional piece of equipment for all-around product purification and equipment protection. Industrial Magnetics Inc., 888-582-0821 Boyne City, MI www.magnetics.com

Sanitary Centrifugal Screener

Sanitary Centrifugal Screener

The Centri-Sifter centrifugal screener features a three-bearing shaft that cantilevers for quick removal of internal components. External roller bearings located at the motor end of the shaft and on a hinged cover at the discharge end provide maximum support and vibration-free operation under heavy loads. When the hinged end cover is open, the shaft cantilevers on a third externally-mounted roller bearing located between the motor-end bearing and material feed point, allowing internal components to slide freely from the opposite shaft end. Equipped with Clean-In-Place (CIP) spray balls for rapid sanitizing using steam or cleaning solution, the unit is constructed of stainless steel finished to industrial, 3-A, FDA, BISSC, and other sanitary standards, and is equipped with a stainless steel motor. Kason Corp., Millburn, NJ 973-467-8140 www.kason.com

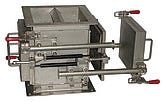

Screen Feeder

Screen Feeder

The Kraus K-Series screen feeder is a screen and feeder combination using a single- or double-deck screen with a brute force drive and a single electric vibrating motor. It is ideal for screening dry granular material from one inch down to 100-mesh particle size. The screen feeder can be flood fed and mounted directly below any size surge hopper and can screen super abrasive materials like silica sand and glass cullet or fine products such as granulated sugar. The replaceable screen deck can be constructed of a 500 Brinell abrasion-resistant steel or screen mesh with openings manufactured to your exact specification as might be desired. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

Gravity Separator

Gravity Separator

The T-20 offers 20 sq ft of separation surface with high volumes of fluidizing air. The gravity separator offers superior separation performance in a rugged and reliable design. Simplified controls assure that machine settings will be trouble- and drift-free. Similar size material is fed onto a flat porous deck which is inclined in two directions. Low-pressure air is forced through the deck to fluidize and stratify the material bed. A vibrating action is applied to the deck to convey the heavier particles up the inclination of the deck. Lighter particles are partially suspended in the rising airflow and slide down the slope of the deck. The final result is a continuous gradation of material from the densest, largest particles to the lightest, smallest particles. Triple/S Dynamics, Dallas, TX 800-527-2116 www.sssdynamics.com

Sifter Decks with Inspection Portholes

Sifter Decks with Inspection Portholes

The inspection porthole on this line of CS-1 gyratory sifters allows easy access to visually inspect 100% of the screen area without the need to disassemble the sifter. The view port is easy to use and requires no tools. You simply unscrew two wing nuts and remove the metal cover plate. The optional view port is available on select decks for the sifter and includes front and rear side portholes with cover plates, self-adhering gaskets for the cover plates, and nylon wing nuts. Retrofitting existing CS-1 sifter decks is possible during the repair process. The inspection porthole facilitates maintenance and sanitation and helps to extend the life of the gaskets and decks. Sifter Parts & Service Inc., Wesley Chapel, FL 800-367-3591 www.sifterparts.com

Sieve Shaker

Sieve Shaker

The Meinzer II has an electromagnetic drive producing the simultaneous vertical and horizontal movement needed for basic dry particle sizing analysis. This gentle motion mimics that of hand sieving processes and therefore produces less wear on your sieves, less sample degradation, and less sieve blinding. With no internal moving parts and a rugged construction, this unit will be maintenance free for years of repeatable use. Sieve analysis has been a widely used procedure in quality control environments for years due to its simplicity. Utilizing an electrical sieve shaker eliminates the need for hand sieving which can be time consuming, and difficult to re-create or duplicate test results. The Meinzer II is precise and gives repeatable results. This unit is ideal for use with sands, cements, chemicals, powder metals, cosmetics, grains, seeds, coal, soils, pharmaceuticals, tobacco, coffee, and many other dry components in ground, granular, or powder form. Advantech Manufacturing Inc., New Berlin, WI 800-511-2096 www.advantechmfg.com

Sieves & Sieve Shakers

Sieves & Sieve Shakers

These sieves and sieve shakers are precise and accurate, while offering good handling, nesting, and strength. A wide range of shakers is suitable for all types of sieving and samples. Sieves are supplied in a complete range of aperture, sizes, diameter sizes, choice in materials, and certified degrees of inspection to meet virtually every requirement. Test sieves can be supplied to a variety of different inspection levels depending on the information requirements specified. Endecotts Ltd, Ponte Vedra, FL 877-743-8372 www.endecotts.com

Gravity Flow Sifters

Gravity Flow Sifters

The QA Tru-Balance gravity flow series operates with a horizontal gyratory sifting motion for precision separations. By using multiple stacked sieves, large amounts of sifting surface can be obtained while using a minimum of floor space. Multiple separations can be achieved with the amount of sieve area for each separation accurately allocated according to product requirements. Other features include: all stainless steel contact surfaces; simple, sanitary sieve frame construction; snap-on food grade neoprene gaskets; elimination of all fasteners in the product zone; elimination of traditional backwire; pneumatic sieve compression system; easy access for inspection, cleaning, and maintenance; wrap-around guards for unsurpassed personnel safety. Great Western Mfg. Co., Inc., Leavenworth, KS 800-682-3121 www.gwmfg.com

Gyratory Sifter

Gyratory Sifter

The GyraMax gyratory sifter can increase a plant’s productivity by reducing the costs associated with routine maintenance and unscheduled repairs. That means fewer production outages and fewer instances of pulling employees away from other duties for unscheduled maintenance. It all adds up to less frustration, greater productivity, and lower production costs. Screen changes are quick and easy, even for multi-deck screeners. You can change any screen at any level of the machine from either end without disturbing the other screens. Screens can still be changed through the top cover, but you won’t need overhead lifting gear to remove a heavy cover. The dust cover is constructed in sections that can be easily removed. With the GyraMax’s easy access doors it’s possible to inspect for major problems without disturbing any of the screens or ball trays. Sweco, Florence, KY 800-807-9326 www.sweco.com

You May Also Like