FDA Purchases eXtended Particle Simulations Tool

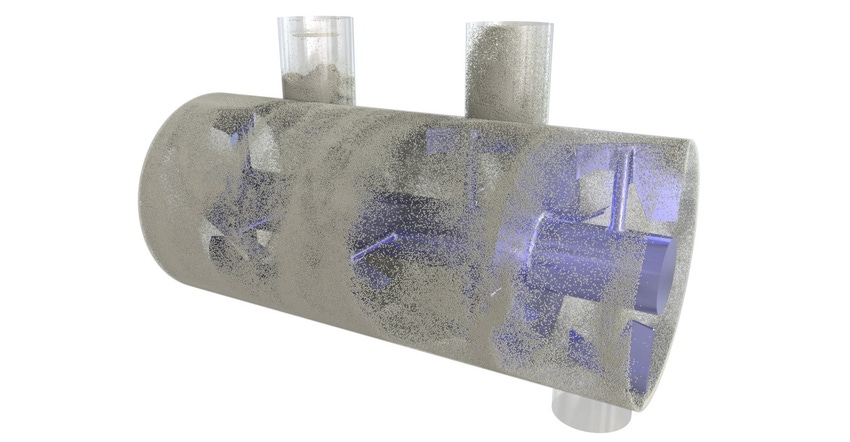

XPS relies on advanced contact models to accurately describe flow behavior of granular materials.

The FDA has recently purchased an XPS (eXtended Particle Simulations) license as an in-house simulation tool, reflecting a trend in the agency's engagement with advanced computational technologies.

XPS is a Discrete Element Method (DEM) simulation software, developed by The Research Center Pharmaceutical Engineering (RCPE) and distributed globally by InSilicoTrials through an exclusive partnership agreement. XPS is renowned for its ability to predict granular processes in great detail, enhancing the understanding, prediction, and control of pharmaceutical unit operations, which leads to improved efficiency and product quality.

The tool relies on advanced contact models to accurately describe the flow behavior of granular materials. Optimized for speed with algorithms designed for modern Graphics Processing Units (GPUs), XPS can handle simulations with up to 100 million particles, ensuring rapid execution and enabling process optimization on even standard desktop machines, RCPE states.

XPS helps to optimize R&D processes by reducing the need for costly and time-consuming physical experiments. Designed specifically for pharma, XPS accurately predicts powder behavior using consumer-grade GPUs to accelerate simulations, while its multi-physics features and digital twin capabilities streamline pharmaceutical manufacturing, enhancing both product development and operational efficiency.

The software's adoption followed a successful project between the FDA and RCPE, which focused on studying powder flow and mixing in a continuous manufacturing line using high-fidelity DEM simulations. The collaboration used XPS to predict Residence Time Distributions (RTDs), for the development of a flowsheet modeling framework based on reduced-order models.

During this process, the predicted RTDs were successfully validated with experimental data collected at the state-of-the-art continuous manufacturing facility at RCPE's pilot plant in Graz, Austria. This framework was used to design an easily configurable control strategy evaluation tool for continuous direct compression processes, allowing for the evaluation of various control strategies.

About the Author(s)

You May Also Like