Spiroflow Unveils Twin-Line Bulk Bag Filling System

The new system addresses the limitations of slow, outdated equipment.

August 14, 2023

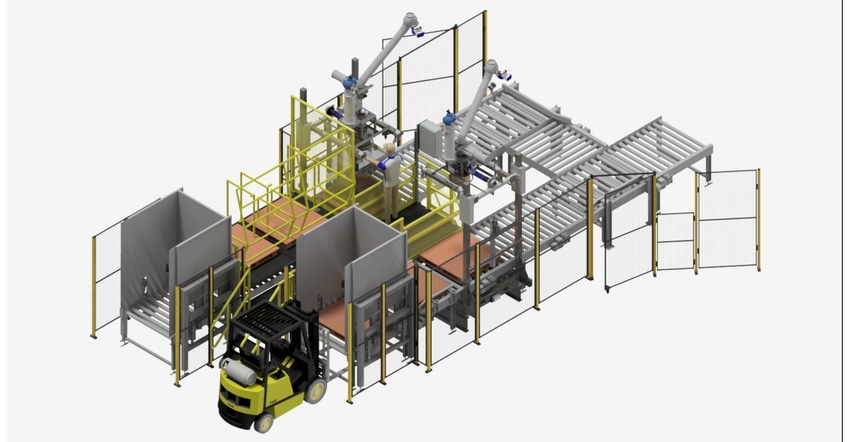

Spiroflow, an Automated Handling Solutions (AHS) company, has launched a next-generation twin-line bulk bag filling system.

After extensive research and development, the new system addresses the limitations of slow, outdated equipment that was prone to spillages and excessive product and dust emissions.

Introducing several key features that enhance production capacity, weigh accuracy, and operator ergonomics, the twin-line system is able to handle up to 20 x 500-kg bulk bags per hour on each process line - a total of 40 bulk bags. Weigh accuracy is a key aspect of the new system as it achieves -0/+500g per bulk bag. This precision ensures consistent and accurate filling of each bag, minimizing product waste and optimizing inventory management processes.

One of the system's design innovations is the incorporation of a raising and lowering filling head, specifically engineered to improve the ergonomic load of empty bags for operators. This feature aims to enhance operator comfort and safety, reducing the risk of workplace injuries.

The integration of auto-release hooks and roller conveyors streamlines the entire filling process, allowing for seamless and automated transfer of full bulk bags from the filler to the conveyors. This automation minimizes the need for manual intervention, further enhancing efficiency.

Each filler is equipped with an integrated and independent dust extraction and filter system. This ensures that product and dust emissions are minimized, maintaining a clean and safe workspace for both operators and the environment.

The system includes a customized platform design that complements its functions and facilitates operator workflows to optimize operational efficiency. This design consideration ensures smooth operations and enhances the overall performance of the filling system.

"We are excited to introduce this revolutionary double bulk bag filling system, which addresses our clients' needs for increased productivity, accuracy, and safety," said Spiroflow’s Rhodri Jones. "This advanced technology not only enhances operations, but also contributes to a more sustainable and efficient working environment. The new system is currently in use with a powder manufacturing company, where it has considerably improved throughput, safety, and efficiency.”

Spiroflow Systems, Monroe, NC 704-859-2085 www.spiroflow.com

About the Author(s)

You May Also Like