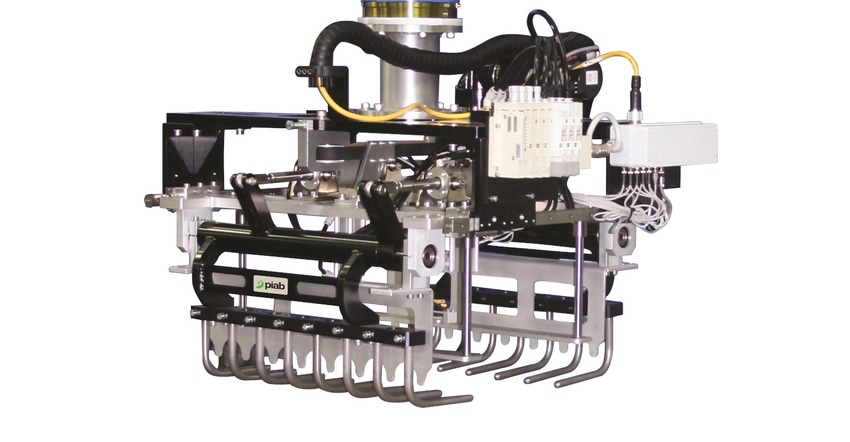

Bag Grippers for Robotic Palletizing/De-Palletizing Operations

Due to the robust and smart design of these bag-gripping tools, operational efficiency is streamlined and maintenance minimized.

June 29, 2020

Created for both standard and custom configurations, all tools are designed to ensure safety of goods and, more importantly, humans. Due to the robust and smart design of the bag-gripping tools, operational efficiency will be streamlined and maintenance minimal.

The EOAT tools are available with a variety of options such as pallet handling, slip sheet systems, sensors, etc.

The bag grippers come in three versions: fixed bag width (FBG), adjustable bag width (ABG), and servo adjustable bag width (SBG).

The FBG model is ideal for handling only a few bag sizes. It can be re-adjusted within four minutes to fit the new bag size. The ABG is for low to medium frequency of bag changes and can be readjusted within 30 seconds to fit the new bag size. The SBG can be adjusted within seconds and is suitable for medium to high frequency of bag changes.

For all models, independent decking plates square-up and align the bag for precise and tight placement on the pallet. Top-mounted clamps maintain the EOAT position during robot travel to the pallet, which also allows for high speed and precision. Slip sheet and pallet hook options are available to increase the flexibility even further.

Piab created digital 3D models of each version that can be tested virtually for compatibility with all industry robots.

Piab, Hingham, MA 781-337-7309 www.piab.com

About the Author(s)

You May Also Like