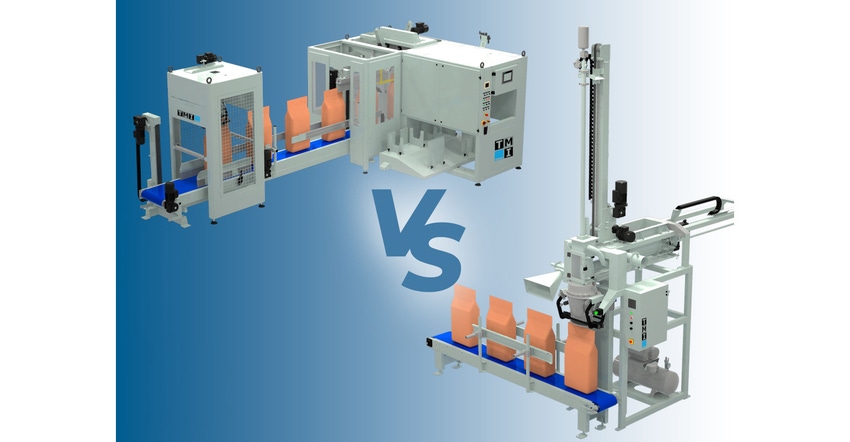

Automatic or Semi-Automatic Bagging: Which is Right for Your Project?

Understanding which type of bagging machine best suits your needs

September 27, 2022

Ariadna Rovira, TMI

“Are you looking for an automatic or a semi-automatic solution?” asks a TMI sales adviser, near the start of a telephone call with a new client.

The voice on the other end of the phone hesitates, “Well...we’re not sure. Could you tell me more about each type’s characteristics?” and the adviser goes on to explain the key differences between the two and their features.

This conversation happens a lot at TMI. And that’s completely natural because our clients tend not to be bagging experts. But we are, so we can help them design their end-of-line project. To do so, various factors must be taken into account. Let’s take a look at the main characteristics of these two types of bagging machine and some key tips for identifying which kind of solution you need for your project.

Semi-Automatic Bagging Machine

A semi-automatic bagging machine is a system for packaging products in bags. Its main function is to precisely weigh out, dose, and insert a solid product into the bag, based on a previously established recipe. It may be equipped with a net weight or a gross weight weighing system, depending on the type of production. However--as its name indicates--a semi-automatic bagging machine cannot function on its own; it needs a human to operate it. An operator must place the bag at the filling point, press a button to start the filling cycle, and remove the bag once it is full.

The main benefits of semi-automatic bagging machines are:

Easy maintenance

Swift cleaning process

Quick return on investment, thanks to its low cost

Easy operation: no need for prior training

Quick, simple installation

Flexible, quick format changes

But they also have their disadvantages:

Production limited by operator efficiency

Need for an operator to be available for bagging

Significant physical effort required from the operator

In what cases is installing a semi-automatic bagging machine advisable? Both net weight and gross weight semi-automatic bagging machines can be used in all industries for a variety of products. But, broadly, they are more suitable for projects with one or more of the following characteristics:

The required bags-per-hour production speed is low

The planned budget for the investment is low

Small batches are being produced or the product is changed frequently, especially if strict hygiene measures must be followed between products, or the product manufacturing speed is low

There are operators available in the area and labour costs are low

There is little space available for bagging

Are all semi-automatic bagging machines the same? Not at all. The type of product to be bagged and the type of bag used are also important to consider when designing the solution that meets your end-of-line needs.

Automatic Bagging Machine

An automatic bagging machine is a packaging system with the same ultimate goal as a semi-automatic bagging machine: to weigh out precise quantities of a solid product and insert them into bags. The main difference is that an automatic bagging machine does this without human intervention. In other words, the machine itself takes the bag, opens it, places it at the bagging point, fills it, removes it from the bagging point, closes it, and ejects it.

Of course, the technology used to carry out all of these processes automatically is more complex than the technology used in manual bagging.

The main benefits of automatic bagging machines are:

Total automation of the bagging process

Optimized production at the bagging point

A single operator can take care of supervision and supply of consumables.

A safer, cleaner workplace

Control over the bag position at all times while it is being handled

But this kind of machine also has some disadvantages:

The initial investment required is usually higher than that needed for a semi-automatic bagging machine.

They usually take up more floor space than semi-automatic bagging machines (though there are some compact versions available).

Installation must be carried out by a qualified technician sent by the manufacturer.

In what cases is installing an automatic bagging machine advisable?

Automatic bagging machines are available for all industries and all products, including animal feed, additives, chemicals, granules, pellets, minerals, and many more. However, an automatic bagging machine is not always necessary. These are some of the key cases in which an end-of-line project will require an automatic bagging machine:

The required bags-per-hour production speed is medium to high.

The product requires you to guarantee a ROI through sustained production and productivity.

There are few operators available in the area or labor costs are high in the country.

Types of Automatic Bagging Machines

Automatic bagging machines can be divided into four main groups: automatic bagging machines for open-mouth bags, automatic bagging machines for SOS bags, automatic bagging machines for valve bags, and automatic FFS bagging machines.

Thanks to this technological diversity, automatic bagging machines can handle different types of bags and materials: flat bags or bags with gussets, made from paper, polyethylene or woven PP (WPP); SOS bags; valve bags; FFS (form-fill-seal) bags, and more. So, automatic bagging machines can handle more types of bags than semi-automatic bagging machines.

How Do I Choose Between All of These Options?

You have probably noticed by now that this issue is a bit more complex than it might first seem. We have therefore put together a series of questions you should ask yourself in order to find the right solution:

What level of production are you aiming for?

What type (or types) of bag will be used?

Will there be more than one bagging format?

How much space is available?

What ROI do you require for the project to be viable?

Is there plenty of labor available near the plant? Or is it scarce?

Now you know the difference between automatic and semi-automatic bagging machines and the importance of specifying the level of automation you need when embarking on an end-of-line project.

Ariadna Rovira, marketing & copywriter, TMI. For more information, call +34 973 25 70 98 or visit www.tmipal.com

You May Also Like