Versatile Mixer for Chemical and Thermal Processing

March 5, 2020

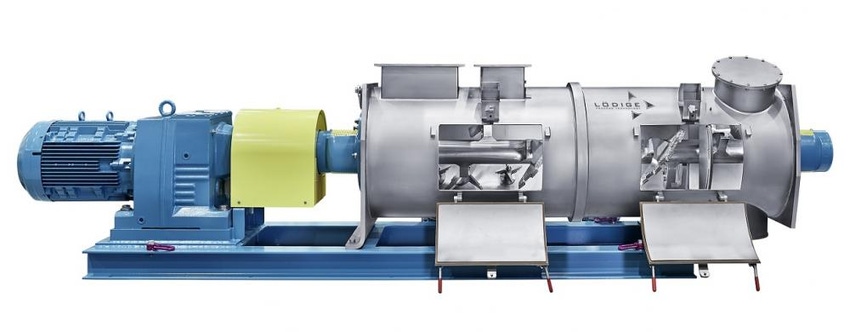

This Ploughshare mixer is a sturdy, durable process engineering system for mechanical, chemical, and thermal processing of sludges, sewage sludges, ashes, dusts, and other waste materials.

Ploughshare mixers are based on the mechanically generated fluidized bed process patented by Lödige. This process involves Ploughshare shovels rotating close to the walls of a horizontal, cylindrical drum. The mixers are available for both batch mode and continuous processes.

The KM series continuous Ploughshare mixers are particularly suitable for environmental engineering applications. This low-maintenance mixer model is intended for processing powders, fibrous, or granular solids, but also fluids and pastes. The continuous mixer even performs granulating processes with minimum retention times. It is characterized by excellent repeatability, maximum homogeneity of the final product, short retention times, and great economic efficiency.

The sophisticated mixer concept also includes universal applicability of the machine. Beyond processing of dry, powdered, granular, or fibrous solids, it can also be equipped for numerous other mixing tasks. Adding fluids to moisten product components is just as possible as processing pastes and fluids. Moreover, installation of choppers in the mixing drum permits breaking up of agglomerated material as well as systematic granulation during the mixing process. A heated and cooled drum, head pieces and shaft are also among the available equipment options. If the machine is subject to particular wear, extremely wear-proof surfaces, high tensile structural steel materials, stainless steel, and special materials increase the high availability of the Ploughshare mixer even further.

Gebr. Lödige Maschinenbau GmbH, Paderborn, Germany +49-5251-309-104 www.loedige.de

Click here for information about the upcoming International Powder & Bulk Solids Conference/Exhibition

Here are more articles that may interest you:

How to Find the Right Mixer for Your Application

Powder Mixing Challenges and How to Overcome Them

Mixer Selection: 3 Tips for Success

Benefits of Tumble Blenders and Dryers

Mixing Strategies for High-Solids Applications

You May Also Like