Ribbon Blenders Handle Demanding Applications

September 29, 2015

Engineered for high-productivity 24/7 operation, Ross ribbon blenders are manufactured in standard and sanitary designs with customizable features for increased reliability of solid-solid and solid-liquid blending operations.

Available from ½- to 1000-cu-ft capacities, these ribbon blenders accomplish a number of processing objectives, from dry powder blending, mixing solids of different shapes and sizes, coating particles with minor liquids, paste mixing, preparing solid-liquid suspensions, and vacuum drying.

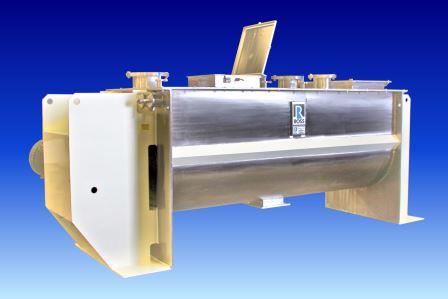

Pictured is a Model 42N-80S ribbon blender with a maximum working capacity of 80 cu ft and 150-grit stainless steel 316 product contact parts. The dust-tight blender cover includes multiple custom ports and a bag dumping station with safety grating. Driven by a high-efficiency 50-hp gearmotor, the double ribbon agitator turns at variable speeds up to 28 rpm (max tip speed of approximately 280 fpm). Due to their direct drive design, the blenders do not suffer from belt slippage, stretching, and wear – issues frequently encountered in lower quality blenders.

During the blending cycle, precise liquid additions are delivered via spray bars with fan-type spray nozzles. In addition, spray balls are installed on the cover for convenient cleaning of the blender’s interior in between batches.

Other customizations such as heating/cooling jacket, end wall scrapers, interchangeable paddle agitator, vacuum capability, abrasion-resistant wetted parts, all stainless steel construction, load cell weighing system, and PLC-based recipe controls are offered as well.

Charles Ross & Son Co., Hauppauge, NY 800-243-7677 www.mixers.com

For related articles, news, and equipment reviews, visit our Mixers & Blenders Equipment Zone

Click here for a List of Mixer & Blender Manufacturers

Click here for information about the upcoming Powder & Bulk Solids Texas Conference/Exhibition

You May Also Like