September 13, 2019

The new Munson model HD-3.5-9-SS ribbon blender features an integral bag dump station that collects dust generated during manual dumping activities, improving worker safety and plant hygiene.

Dust is drawn onto cartridge filters of the dust collector as nozzles within each filter alternately emit short blasts of air on a timed cycle, serving to dislodge accumulated dust and maintain vacuum efficiency.

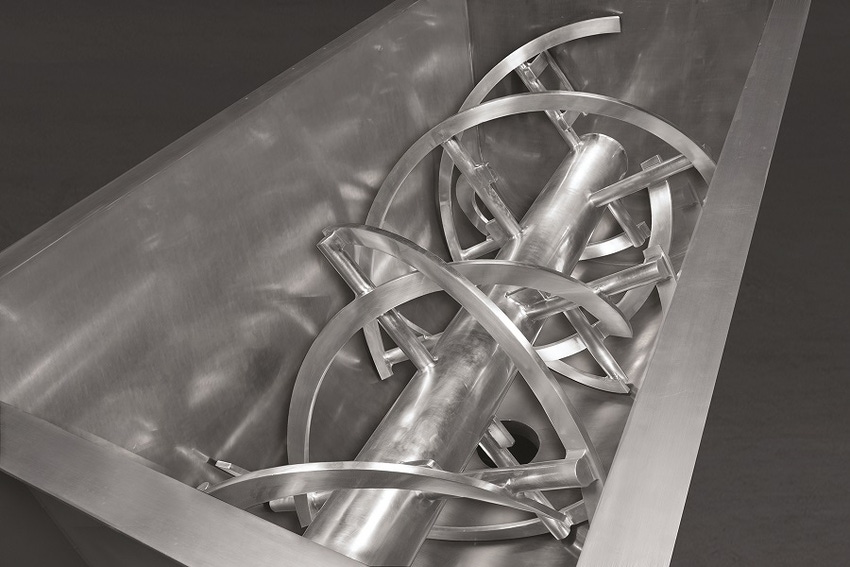

The unit can blend up to 85 cu ft of powders, pastes, or slurries in five to 10 minutes depending on application. Its length-to-diameter ratio and split double-helical agitator reduce the time required to uniformly distribute particles having dissimilar sizes, shapes, and bulk densities throughout the batch.

Tight tolerances of 1/8 to 1/16 in. between the ribbon blades and the vessel trough minimize residual product following discharge, reducing material waste and cleaning time.

Hand-held sacks are slit and dumped through a welded grate which helps trap oversized lumps and bag scraps, as airborne dust is drawn away from the operator.

At the opposite end of the blender, a hinged lid with removable, safety-interlocked grate as standard provides access to the vessel interior for cleaning and inspection.

Powered by a 30-hp motor and constructed of stainless steel, the unit is available to industrial, pharmaceutical, and food-grade standards, ranging from clean mill finishes to 2B, #4, and #7 mirror pharmaceutical finishes to sanitary USDA Dairy finishes with electroplating and chemical passivation.

Other options include a removable safety-interlocked grate on the dump station for additional interior access, spray lines for liquid additions, a central inlet port, multiple discharges, special drive arrangements, and CIP manifolds. Models range in capacity from 1 to 1150 cu ft.

Munson Machinery Company, Inc., Utica, NY 800-944-6644 www.munsonmachinery.com

Here are more articles that may interest you:

Mixer Selection: 3 Tips for Success

Benefits of Tumble Blenders and Dryers

Mixing Strategies for High-Solids Applications

Contract Powder Blenders Optimize Production for Cosmetics, 3D Printing

You May Also Like