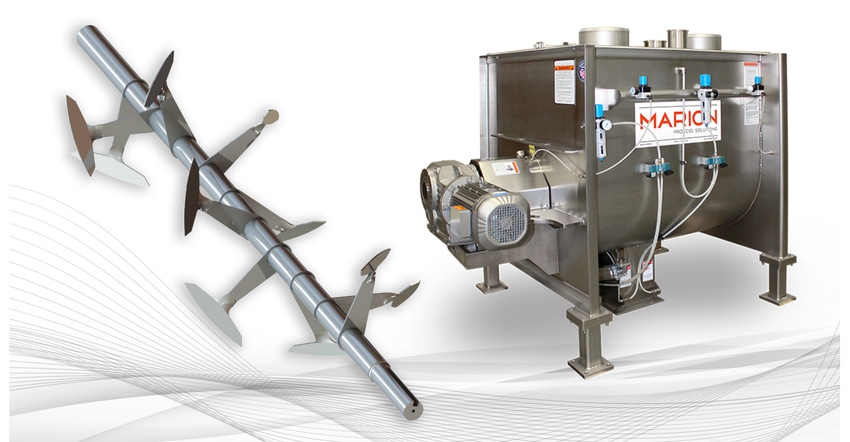

New Agitator Design for Horizontal Mixers Reduces Lead Times

New plated paddle agitators are manufactured with paddle and arm sections cut from a single piece of stainless steel.

December 5, 2023

Marion Process Solutions, an Advanced Material Processing (AMP) brand, introduces a new agitator design for its 30-in.-diam and smaller horizontal mixers.

The release provides customers with not only a two-week reduction in lead times but also up to 10% savings on the purchase price.

The new plated paddle agitators are manufactured with the paddle and arm sections cut from a single piece of stainless steel, reducing welding requirements and offering operators low-maintenance cleanability. Due to the integrated placement hole design, additional arms are attached, which means that the length of the paddles is shortened to offer improved mixing efficiency.

Tailored specifically for shear-sensitive materials and challenging-to-mix substances with diverse densities, these horizontal mixers armed with the new plated paddle agitators are a perfect fit for a wide spectrum of industries. Key sectors set to benefit include food processing, pharmaceuticals, chemicals, and cosmetics.

Marion Process Solutions, Marion, IA 800-397-6371 www.marionsolutions.com

About the Author(s)

You May Also Like