Mixing & Blending 1832

June 7, 2011

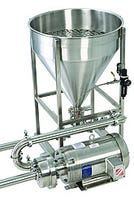

Bench-Top In-Line Mixer

Bench-Top In-Line Mixer

A bench-top in-line mixer, the Verso is ideal for pilot-scale or laboratory applications. Controlled from a digital operating touch pad, it offers excellent reproducibility when scaling up, and with a tachometer, ammeter, and programmable timer, it provides an accurate and easy method of forecasting the performance of larger in-line mixers under full-scale conditions. The Verso complements Silverson’s lab range of equipment, providing the next step in the scale-up process. The 1-hp machine has a self-pumping flow rate of 6.5 gal/min (depending on product viscosity). A full range of interchangeable workheads is available for the Verso, allowing it to perform the widest range of mixing duties, including blending, emulsifying, homogenizing, solubilizing, suspending, dispersing, particle size reduction, and reaction acceleration. Silverson Machines Inc., East Longmeadow, MA 413-525-4825 www.silverson.com

Versatile Batch Blender

Versatile Batch Blender

This 45-cu-ft paddle blender was custom designed for toll blending a variety of proprietary food recipes. The machine efficiently mixes powders, granules, pastes, or slurries. The paddle style agitator can mix fragile ingredients like nuts, fruits, and vegetables without breakage. All internal surfaces are ground smooth and polished for easy cleaning. The 304 stainless steel construction is corrosion resistant. High-speed choppers are available for incorporating minor ingredients or size reduction of lumps. The one-piece cover is hinged with a pneumatic actuator and simplifies operation by ensuring the lid forms a dust-tight seal when closed. This blender is ideal for mixing a wide variety of recipes and batch sizes. Marion Mixers, Marion, IA 800-397-6371 www.marionmixers.com

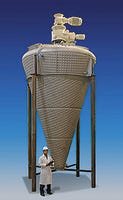

Vertical Cone Screw Blender

Vertical Cone Screw Blender

This vertical cone screw blender easily handles all types of materials that include powders, solids, pellets, and grains, to deliver quick and precise mixing of batches in a single vessel with non-segregation during discharge. The rotating screw does not have a bottom bearing support, thereby eliminating any dead spots or difficult areas to clean, and allowing for full bore open discharging of the product. Discharge of the material is fast and simple. Rotating with the mixing screw is a spray nozzle that allows the user to inject liquid or gas ingredients into the batch or use this feature for automatic CIP cleaning. For more intense mixing a sidewall mounted lump breaker can be incorporated. Bolz-Summix, Swedesboro, NJ 856-241-9970 www.heinkelusa.com

Powder-Liquid Blending Equipment

Powder-Liquid Blending Equipment

Minimizing air entrainment, increasing repeatability, improving operator ergonomics, and eliminating waste are all challenges facing today’s processors. This range of sanitary mixing and blending equipment helps resolve these issues. Determining the best method of drawing powders into liquids is now easier. Mixing equipment covers the range from simple eductors for easy-to-disperse solids, through inline blending, up to a complete skid system with integral high-shear dispersion and vacuum deaeration capabilities. Admix Inc., Manchester, NH 800-466-2369 www.admix.com

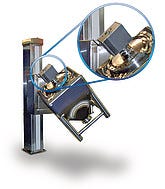

Inline Miniature Rotary Batch Mixer

Inline Miniature Rotary Batch Mixer

This inline miniature rotary batch mixer gently blends batches up to 5 cu ft in parts as small as one per million with complete uniformity in less than three minutes, evacuates the batch with no residual, and can be sanitized rapidly with no tools. The Model 700-TH-5-SS stainless steel unit features a stationary inlet and outlet for inline operation, and a rotating drum with proprietary mixing flights that tumble, turn, cut, and fold material gently. Equally efficient across its useable capacity range of 5 to 0.25 cu ft, the mixer has a batch weight capacity of 500 lb as standard, with higher capacities optional. The internal flights elevate material facilitating complete discharge, allowing rapid cleaning of all-stainless contact surfaces including continuous polished welds having 0.25 in. radii. Munson Machinery Company, Inc., 800-944-6644 www.munsonmachinery.com

Blend Processing System

Blend Processing System

This blend processing system reduces costs and speeds production by: cutting costly lab analysis; eliminating thief sampling; providing real-time uniformity results; insuring real-time consistent blend uniformity by adjusting blender parameters; validating each batch to achieve real-time release. The system is a true “plug and play” near-infrared PAT system for blend uniformity analysis for IBC tumble blending. The design consists of a self-contained, battery-operated wireless NIR diode array spectrometer mounted on the blending container with a quick-release clamp. The wireless signal can be received up to 1000 feet away from a wireless PC running the system’s proprietary software. Custom Powder Systems, Springfield, MO 417-868-8002 www.custom-powder.com

Cantilever Shaft Mixers and Blenders

Cantilever Shaft Mixers and Blenders

Booth 657 - This full range of Gardner mixers and blenders features the easy-clean cantilever shaft. The cantilever design agitator shaft eliminates one set of bearings and seals at the non-drive end of the shaft. This, along with the full diameter hinged and safety, interlocked door improves access for cleaning and hygiene. The completely contained mixing media provides an ideal environment for dry, semi-dry, or moist powder applications. Gardner mixers and blenders are available in various designs with a choice of plough, paddle, or interrupted spiral agitator. Also available from the Gardner line are double cone blenders, continuous mixers, stirred bunkers and processors, and reactor mixers. Kemutec, Bristol, PA 215-788-8013 www.KemutecUSA.com

Batch or Continuous Mixer

Batch or Continuous Mixer

The batch or continuous mixer is a proven design for fast, accurate mixing of small amounts of active ingredients in a batch to provide a uniform, homogeneous mix. The mixer is manufactured in accordance with GMP and can be specified to meet all the sanitary requirements by the FDA, 3A, USDA, and of the pharmaceutical industry, including the ease of cleaning. The plow shape mixing tools develop a medium intensity mix action, which is gentle yet thorough. High-speed choppers that quickly disperse minor liquid or powder ingredients may supplement this action. Extremely versatile, the mixer not only is capable of precise mixing, but also agglomerates/granulates to consistent particular size distribution in a two-step process. Littleford Day Inc., Florence, KY 800-365-8555 www.littleford.com

Powder Dispersing/Deagglomeration Machines

Powder Dispersing/Deagglomeration Machines

Microtron MB 550/800 powder dispersing/deagglomeration machines are specifically designed for mixing, dispersing, homogenizing, and deagglomerating powdery material with both low and high densities. There are four different sized glass attachments for the MB 550 (125, 250, 500, and 1000 ml) and two stainless steel attachments (2000 and 4000 ml) for the MB 800. Safety is built into the units to prevent operation without a safety covering over the glass vessels, and, should the covering be removed, the unit will stop. Other features include: a powerful, high-speed motor; electronic speed control; soft start and blades made from stainless cutlery 316 stainless steel. Applications include deagglomeration of clumps in pigments or cosmetic powders, incorporation or dispersion of small amounts of powders in liquids, as well as other applications for the food industry. Kinematica Inc., Bohemia, NY 631-750-6653 www.kinematica-inc.com

Double-Shafted Fluidized Zone Mixer

Double-Shafted Fluidized Zone Mixer

Booth 125 - The Bella XN double-shafted fluidized zone mixer includes access doors that not only increase accessibility but also make it easier to clean when necessary. The mixer achieves fast, high-capacity, low-shear, precision mixing of either dry bulk solids or liquids with solids. Regardless of particle size, shape, or density, materials are mixed with a fast, efficient, and gentle action, with typical mixing times 60 seconds or less. A weightless zone created by low-speed counter-rotating shafts generates low friction without shear, making it ideal for fragile products that cannot tolerate rough handling. Even flakes or spray-dried bodies remain intact. The mixer includes twin bomb-bay door openings for fast, efficient discharging and to minimize segregation during discharge. The unit is available in stainless steel for sanitary applications. Custom sizes, finishes, and materials of construction are available upon request. Dynamic Air Inc., St. Paul, MN 651-484-2900 www.dynamicair.com

Double-Ribbon Agitator

Double-Ribbon Agitator

Booth 331 – With a reverse-spiral design, the double-ribbon agitator delivers uniform, high-capacity blending at low power cost. The mix is held in constant suspension providing for uniform mix of the product. Paddle assemblies mix using a tumbling motion and have less product shearing during the process. Units are built to food or dairy standards. More than 16 standard models are available from 7 to 476 cu ft. Custom models available up to 1500 cu ft. Mixing is accomplished using either a ribbon or paddle agitator. S. Howes Inc., Silver Creek, NY 716-934-2611 www.showes.com

Vertical Blenders

Vertical Blenders

These vertical blenders are ideal for efficient and thorough blending of solids. This type of blender features an auger that turns on its own axis and a mechanical arm that rotates the auger around the conical vessel. The blending action is far gentler than that of horizontal blenders, making it more suitable for delicate and abrasive applications. Spray nozzles may be installed for liquid addition and coating purposes. Vertical blenders are also commonly used in vacuum drying operations and can accommodate a wide range of feed forms – from slurries, wet cakes, and pastes, to granules, pellets, and powders. An important standard design feature is the absence of a bottom support bearing. This facilitates complete discharge and simplifies cleaning. Many sizes from 1- through 500-cu-ft capacities are available, including sanitary models. Charles Ross & Son Co., Hauppauge, NY 800-243-7677 www.mixers.com

Powder and Liquid Delivery System

Powder and Liquid Delivery System

Booth 725 - The Solidquid powder and liquid delivery system automatically and precisely delivers dry bulk ingredients into a motive liquid stream to convey slurries, solutions, or suspensions into a mix tank, blender, or other process equipment. In addition to reducing mix times, the Solidquid instantly creates non-viscous mixtures, which eliminates the need for additional conveyors, saves maintenance and energy costs, creates less dust, uses less floor space, and offers more flexibility in equipment layout. Material is discharged from a bulk bag unloader frame into a feeder, which volumetrically or gravimetrically measures it into a solids eductor. Motive process liquid supplied to the eductor inlet creates a vacuum, pulling the dry material into suspension and disperses them evenly into the effluent flow. Hapman, Kalamazoo, MI 800-427-6260 www.hapman.com

Continuous Mixer

Continuous Mixer

Designed for use as an on-machine or central station blender, the ProBlend mixer precisely meters and mixes materials at various throughputs and blend ratios. Utilizing a compact hopper with an adjustable speed impeller, the ProBlend’s continuous mixing action consistently delivers a homogeneous blend. Equipped with an optional instant access hopper door with quick-release latches, the mixing chamber and impeller can be easily cleaned without being removed. Positions are provided for up to four high-precision ProRate feeders that can simultaneously meter additives or colorants into the blending hopper. ProRates can be added or removed to accommodate future application requirements. K-Tron Process Group/K-Tron Premier, Salina, KS 785-825-1611 www.ktron.com

Blender Conveyors

Blender Conveyors

Stationary and portable CB Series blender conveyors combine bulk carrier unloading, transfer, and blending capabilities in one vacuum-pressure unit. They are sized for 5 to 20-plus tn/hr and can handle powdered, granular, or pelletized abrasive materials that are friable. Equipped with automated controls and load cells, these machines blend products from multiple sources and convey them to one or more destinations using a single 15-psig positive-displacement blower. Proprietary semi-dense design results in low line velocities and high material-to-air ratios that reduce wear and product degradation. Cyclonaire Corp., York, NE 888-593-6241 www.cyclonaire.com

Gourmet Tea Batch Blender

Gourmet Tea Batch Blender

The Rollo-Mixer Mk VII-1 is a versatile rotary drum batch mixer that is capable of blending and flavoring tea in batch sizes ranging from 25 to 25,000 lb at a time. The blender folds and divides each batch uniformly, without damaging tea leaves or ingredients at a nominal 3 RPM. Dry enhancements are distributed gently and evenly in nine revolutions. At the same time, the surface area of the batch is exposed to receive precise amounts of liquid flavors through “Free-Fall Processing”, exclusive to the Rollo-Mixer. Batch to batch consistency is uniform. There is no fractured product resulting in “mechanically hand-blended teas” in less than three minutes. Continental Products Corp., Milwaukee, WI 715-597-3106 www.continentalrollomixer.com

Automated Bulk Material Mixing System

Automated Bulk Material Mixing System

Booth 763 - Designed specifically for fully automated introduction, transfer, mixing, and blending of multiple, sluggish materials, this integrated mixing system produces such homogenous blends that downstream production scrap is virtually eliminated. A lift-and-seal gaylord dumper system, with a dust-tight, custom discharge hood, introduces the material into the transfer bin. An integrated agitator and vacuum pump transfer system supply material to the high-volume material mixer. Within the mixer, a 16-in.-diam auger mixes material in a 17-in.-diam, 10-gauge mix tube. In-feed scoop blades at the base of the mixing auger, and broad-throw dispersion paddles at the top of the mixing auger ensure a homogenous and consistent blend supply to downstream processes. National Bulk Equipment Inc., Holland, MI 616-399-2220 www.nbe-inc.com

You May Also Like