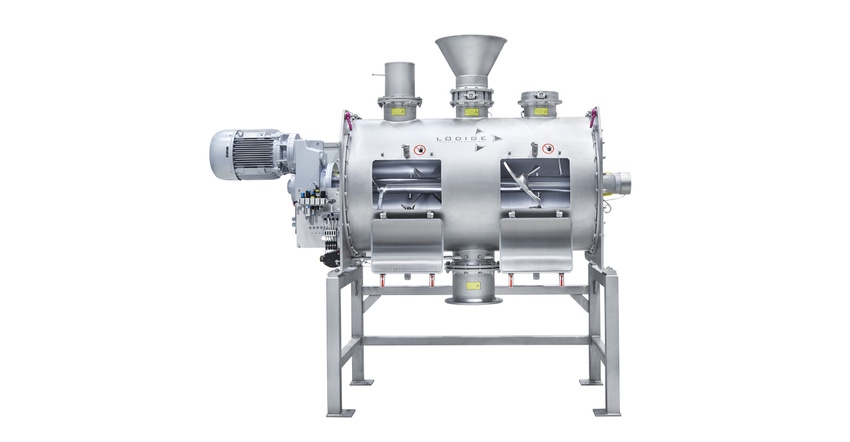

Lödige Offers New Ploughshare Batch Mixer

Standardized model increases cost efficiency.

October 5, 2023

Lödige's FKM series Ploughshare batch mixers are designed for the treatment of powdered, granular, or fibrous bulk solids. Their main advantages are short throughput times, excellent mixing quality, and high batch reproducibility.

Like customized machines, the new FKM mixers of the "light series" are manufactured entirely at the Lödige headquarters in Paderborn/Germany. They differ from customized solutions due to their standardized design. Another advantage is the reduction in delivery times for the FKM LS series to three to four months, a significantly shorter period than that for customized special machines.

The new mixers are available in seven sizes from 130 to 3,000 l and designed for a clearly defined range of functions. At the same time, numerous standardized options permit optimal adaptation to the relevant product and process requirements. For instance, separately driven choppers rotating at high speeds can be used to support the effect of the mixing element. Other equipment options include liquid injectors, a product thermometer, different control systems, and an explosion-proof ATEX version.

Gebr. Lödige Maschinenbau GmbH/Lödige Process Technology, Paderborn, Germany +49-5251-309-260 www.loedige.de

About the Author(s)

You May Also Like