Hybrid Mixers Prevent Lumping in Food Production

October 3, 2016

Alfa Laval, a leading global provider of specialized products and engineering solutions, has developed a versatile new system for high-speed dispersion of even the most challenging powdered ingredients.

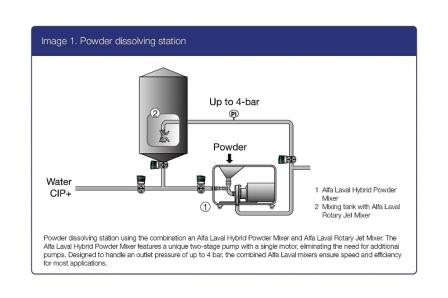

Used in combination with the Alfa Laval rotary jet mixer, the hybrid powder mixer maximizes uptime while reducing initial investment, and operating and maintenance costs (see Image 1).

Powders are ingredients common to the modern food industry. Difficult-to-disperse powders often pose a significant challenge to food manufacturers due to the formation of lumps or "fish-eyes" during processing. Together, the hybrid powder mixer and rotary jet mixer offer a way to deal with powder dispersion issues. Food manufacturers can now take advantage of optimal mixing efficiency and low cost of ownership. By combining the two components into a single, highly effective system, Alfa Laval enables instant and uniform dispersion of even the most challenging powdered ingredients using a single motor.

Unlike conventional powder mixers, the hybrid powder mixer creates high dynamic shear in three steps using a single motor shaft (see Image 2). This requires less energy than a conventional two-motor powder mixer, to ensure complete dissolution of the powder. The hybrid powder mixer features a two-stage pump, one high-shear stage and one pump stage fitted with a motor with a frequency converter. The pump enables an output pressure of up to 4 bar without requiring an additional pump. It also drives the circulation loop to the mixing tank (see Image 3).

Installed inside the mixing tank on the circulation loop, the rotary jet mixer, a rotating four-nozzle device is powered by the product flow and pressure from the hybrid powder mixer. The rotary jet mixer (see Image 4) can disperse the most challenging powdered ingredients and ensure product homogeneity without having to add an agitator. It is an effective tank-cleaning machine for the mixing tank and it saves time, reduces energy consumption, and boosts production capacity.

For related articles, news, and equipment reviews, visit our Mixers & Blenders Equipment Zone

Click here for a List of Mixer & Blender Manufacturers

You May Also Like