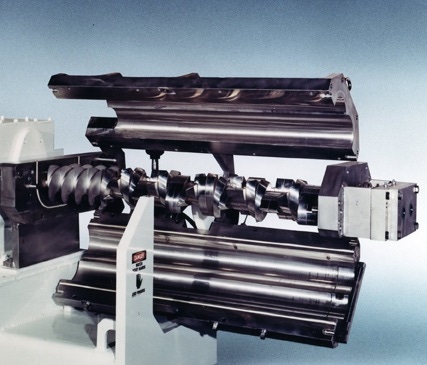

Continuous Processors Feature Double Clamshell Barrel Design

January 7, 2020

Continuous processors from Readco Kurimoto feature an optional, double clamshell barrel design that allows 360 degree access to the entire paddle and screw assembly to promote thorough, complete cleaning, confident visual inspection, and easy adjustments to the configuration.

Eliminating the need for cumbersome cranes and hoists often used to raise the barrel, the double clamshell design enables the barrel top, bottom, or both top and bottom to be easily opened at the push of a button. Once opened to reveal the interior, the system automatically locks the barrel in the open position for safe cleaning and maintenance. When ready, the double clamshell barrel closes at the push of a button, sealed and ready for operation.

Ideal for food, plastics, chemical, pharmaceutical, and other processors, the double clamshell design virtually eliminates the potential for cross-contamination, providing valuable versatility for processors interested in producing multiple product formulations with powders, liquids, and/or viscous materials on a single, compact unit. Continuous processors with the double clamshell design are custom engineered to suit each installation based on product testing conducted on full-size equipment in the company's on-site testing lab.

Readco Kurimoto LLC, York, PA 800-395-4959 www.readco.com

Here are more articles that may interest you:

Powder Mixing Challenges and How to Overcome Them

Mixer Selection: 3 Tips for Success

Benefits of Tumble Blenders and Dryers

Mixing Strategies for High-Solids Applications

You May Also Like