Explosion Protection for Metal Dusts/Shot Peening Plants

May 23, 2019

Metal dust explosions are hot stuff: the combustion temperature and energy are considerable--and considerably higher than those for other types of dust. Temperatures can reach 5400°F or higher, not to mention the other consequences of an explosion such as a sudden pressure rise. As a result, many metal working industries, including the automobile industry and its suppliers, face major and very expensive challenges when it comes to explosion safety. This is especially true when the machinery that needs to be protected is located indoors.

Until now, most companies have used wet scrubbers to mitigate the dangers of metal dust explosions. However, the sludge produced by these systems is not only difficult to handle but also expensive to dispose of correctly.To solve these problems, one automobile manufacturer began searching for an alternative solution to protect shot peening (steel shot used for surface hardening) plant filters.

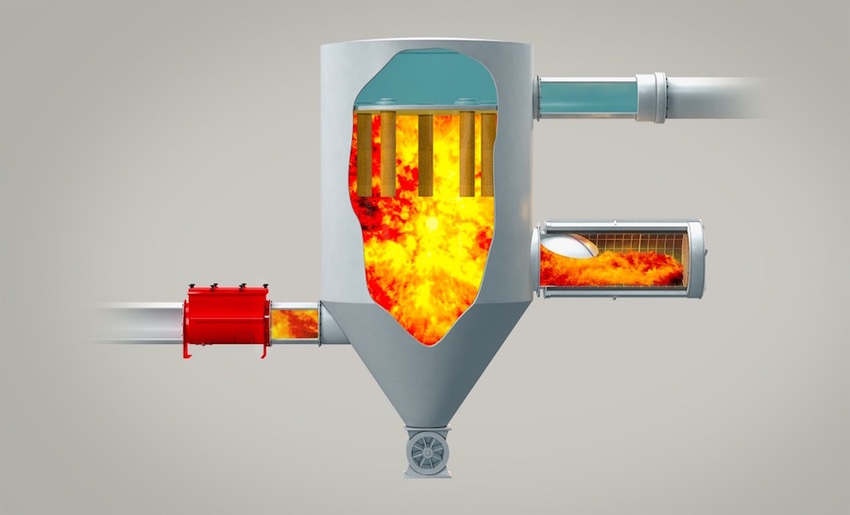

Fig. 1

The abrasive grains used in centrifuges, compressed air and injector plants “strike” the work-in-process at a high velocity. These “strikes” produce metal dust, which is extracted by a filter. When the filter elements are cleaned, there is an increased risk of a combustible dust explosion.

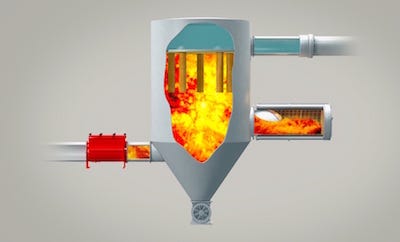

Fig. 2

Cool Q-Rohr

The automobile company learned about the REMBE Q-Rohr (Fig. 2, Fig. 3), the first flameless explosion vent certified for use with metal dusts. This product is an innovation developed by REMBE, the explosion safety experts with more than 40 years of experience in the industry. Roland Bunse, who has more than 20 years of experience as an explosion safety specialist at REMBE, says that REMBE wanted to develop a cost-effective indoor explosion protection solution for customers in the metalworking industry.

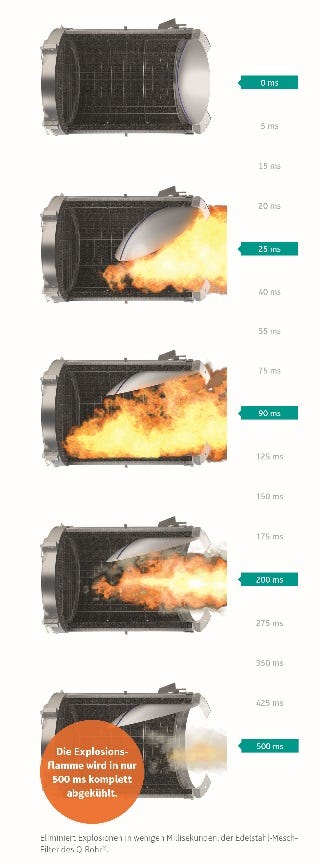

Fig. 3

In the 1980s, REMBE revolutionized explosion protection solutions with the introduction of the Q-Rohr. Since then, with decades of experience in every area of the bulk materials industry, REMBE was able to identify a solution which is suitable for metal dusts. The Q-Rohr is the only product for flameless explosion venting in metal dusts applications certified in accordance with EN 16009 and compliant with NFPA standards. Q-Rohr is certified for iron, steel, silicon and aluminum dusts.

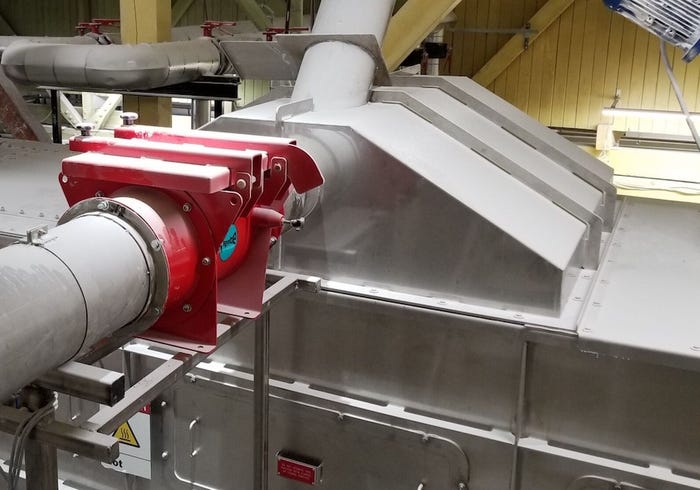

Fig. 4

When used in combination with the Q-Flap NX explosion isolation valve (Fig 1, Fig. 5, Fig. 6), certified in accordance with En 16447 and compliant with NFPA standards, the Q-Rohr guarantees the safety of plant equipment, buildings and employees in the event of an explosion.

Fig. 5

How does the Q-Rohr work?

Heat generated from a metal dust explosion can reach temperatures of up to 5400°F but is cooled very efficiently by energy dissapation due to the special stainless steel mesh inset developed specifically for the Q-Rohr. This metal mesh inset reduces the volume of the escaping heat and extinguishes the flame. In addition, the typical pressure increase and noise in the plant resulting from an event are reduced to a barely perceptible level. And, the stainless steel mesh ensures that no burned or unburned dust particles escape. The system provides the optimum protection for the environment against both the explosion and its consequences. (Fig. 4)

Fig. 6

The Q-Rohr is mounted using standard flanges. No special training or knowledge is required and the product is installed in just a few minutes. Installation of a replacement after an explosion is equally quick, which reduces the resulting production downtime significantly (Fig. 7).

Fig. 7

Advantages of flameless explosion venting with the Q-Rohr:

· The complete production process remains in the building.

· No running costs either for the disposal of sludge (wet scrubber), shavings or external maintenance. Only a visual inspection is required.

· Proximity to an external wall is not required.

· The signalling unit is integrated for reliable monitoring

· Reduction of the noise level and pressure rise typically associated with explosions to an acceptable level.

As the inventor of flameless venting, REMBE specializes in combustible dust explosion prevention/protection systems for many applications across a multitude of industries. REMBE, Inc., located in Charlotte, NC, serves the North American market.

Get information or register for Powder Show Toronto, June 4-6, 2019

For more news headlines, articles, and equipment reviews, visit our Equipment Zones

You May Also Like