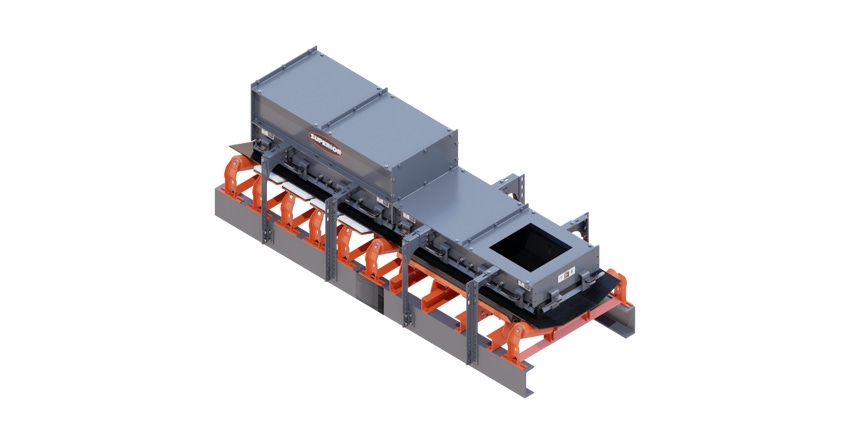

New Skirting System Controls Conveyor Dust Emissions

System retrofits to any brand of existing structure with little or no field fabrication

January 3, 2023

Superior Industries Inc. introduces an easy-to-install modular skirting system that controls dust and prevents spillage within conveyor load and transfer zones.

“Our crews visit and collect data from thousands of conveyor systems each year and we figure about half of them would benefit from material containment components,” said Paul D. Schmidgall, chief engineer in Superior’s conveyor components division. “That’s one out of every two conveyors spilling valuable material, spewing harmful dust, and creating unsafe work environments.”

The new skirting system retrofits to any brand of existing structure with little or no field fabrication. Two sets of adjustable legs aid in this universal installation. Easy-to-adjust clamping mechanisms are used in place of nuts and bolts to hold skirtboard rubber tight against the belt. An optional stilling zone is available to accelerate the settling of dust while material is moving inside the system.

The modular skirting system is available in 5-ft sections for conveyor belt widths up to 72 in.

Superior Industries Inc., Morris, MN 320-589-2406 www.superior-ind.com

About the Author(s)

You May Also Like