Maximize Conveyor Uptime with Total Preventative Maintenance

Implementing a total preventative maintenance plan with the assistance of an expert OEM can help optimize uptime and system longevity.

When processors of dry particulates depend on tubular drag cable conveyors to transfer powder and bulk solids from one location to another, it can be a costly mistake to run the equipment until something breaks or needs to be repaired, which can lead to significant unnecessary downtime. A far better solution is to sufficiently design and install as well as effectively maintain the conveyors to maximize production uptime and lifespan.

Fernando Mejia, director of product life cycle management & aftermarket for Automated Handling Solutions (AHS), explained to Powder & Bulk Solids readers how to optimize conveyor uptime and longevity with a total preventative maintenance approach and answered questions. AHS combines the strengths of Cablevey Conveyors and Spiroflow to provide a specialized handling and automation product portfolio for mission-critical applications.

Q: In terms of conveyors, would you explain to our readers the difference between traditional maintenance, total preventative maintenance, and the benefits to them?

A: Processors traditionally have relied on third parties such as local millwrights to install and maintain conveyors. These third parties may not have access to technical specifications or have not had the opportunity to read the manual and can therefore be unaware of system acceptable specifications and best practices. This can result in not only excessive downtime and maintenance, but also costly repairs and even premature system replacement.

Instead of reacting to individual problems as they arise, a more effective approach is to implement total preventative maintenance (TPM) for conveyors. This involves ongoing service and engineering support, resulting in reduced downtime and lower operations and maintenance (O&M) costs.

The goal of a TPM program is to work with processors to maximize the output of their conveyors and extend the lifespan of their critical capital equipment.

Q: As conveyors get more sophisticated, how important is preventative maintenance?

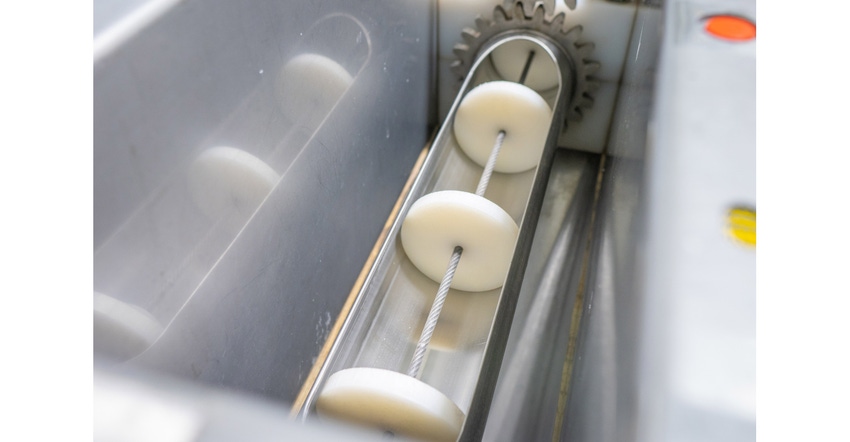

A: With the sophistication of state-of-the-art conveyors, proactive, preventative, and predictive maintenance is an effective strategy. This is the case with tubular drag cable conveyors, which gently move product through a sealed tube using a coated, flexible stainless-steel drag cable pulled through on a loop. Solid circular discs (flights) are attached to the cable, which propel the product through the tube without the use of air.

Q: How can OEMs make preventative maintenance easier for processors?

A: While it is possible to utilize third parties to install the systems and in-house maintenance teams to maintain them, there are considerable advantages to involving an OEM Supervisor, since they possess unparalleled training and expertise on the system.

OEM technicians typically have years of experience exclusively servicing and troubleshooting tubular drag style conveyors. Some OEM technicians have conducted hundreds of inspections in plants worldwide that run any material imaginable, from powders and blends to bird seed, pet food, cereals, coffee beans, nuts, and more.

Many recurring problems stem from incorrect installation, which can involve improperly positioning the conveyor’s hangers, excessive tension, misaligning tubing, leaving gaps, or insufficient supports. All these defects can generate friction, noise, and prematurely wear parts, requiring replacement.

An OEM can also proactively recommend the appropriate spare parts kits or high wear parts such as cables, connectors, or sweeps that are known to have shorter lifecycles. This method encompasses assessing both the condition and usage of the conveyor, while also leveraging predictive data to efficiently resolve numerous issues before any downtime occurs.

An experienced OEM can analyze system usage as well as component wear and lifecycle data to accurately predict when vital parts will likely need to be replaced and have them replaced before something breaks.

The more a processor adheres to this type of total preventative maintenance schedule, the more likely the conveyors will provide optimal service throughout their anticipated lifespan.

Q: How important is annual conveyor inspection? What should be inspected?

A: A comprehensive annual inspection of the conveyor system by the OEM is highly recommended. With the shortage of skilled mechanics combined with high employee turnover, the OEM can perform in-depth inspections and recommended maintenance. This solution is mainly targeted to processors that have one or multiple tubular drag conveyors running constantly throughout the year.

Detecting problems such as gaps or misalignments requires camera inspection. The annual inspection also assesses the conveyor’s tubes, walls, sweeps, connectors, input, and output. In addition, cables should be checked for integrity and tension, discs and sprockets for wear, and joints should be validated.

During the inspection process, the OEM can recalibrate or replace any components outside of system specifications. OEM service technicians also advise on the use of any available update or retrofit kits that can further facilitate increased output.

Q: What factors determine how often conveyors should be inspected?

A: While the frequency of the annual service visits depends on the system application and environment conditions, several factors can help determine the optimal frequency. As a partial list, this can include the type of conveyor systems in the facility, system length and complexity, average daily use, environment conditions and the type of material conveyed. When these factors are analyzed, a service visit might be scheduled once or twice per year, as the situation warrants.

Q: Can you give an example of a processor that could benefit from preventative maintenance?

A: Many processors can benefit greatly from collaborating with a knowledgeable conveyor OEM to establish a comprehensive preventative maintenance plan. This was the case when a coffee processor aimed to revamp its maintenance strategy.

This customer had expanded operations and was about to double their capacity. Although their conveyors were running well, they didn’t want to risk unnecessary downtime. So, they informed the OEM that they would like to avoid the “break/fix” approach and move forward to a total preventative maintenance culture.

Q: Given the benefits of preventative maintenance, what are OEMs doing to make it easier and more available to processors?

A: To meet the demands of the industry and address the requested services, some OEMs are increasing service capacity to assist processors in proactively mitigating issues and minimizing downtime.

Reacting to conveyor problems has essentially been the default for many busy processors. However, implementing a total preventative maintenance plan with the assistance of an expert OEM can help optimize uptime and system longevity.

For more info, call 641-673-8451, email [email protected], or visit automatedhandling.com.

About the Author(s)

You May Also Like