Conveyor Eliminates Chemical Processing Safety Risks

March 30, 2020

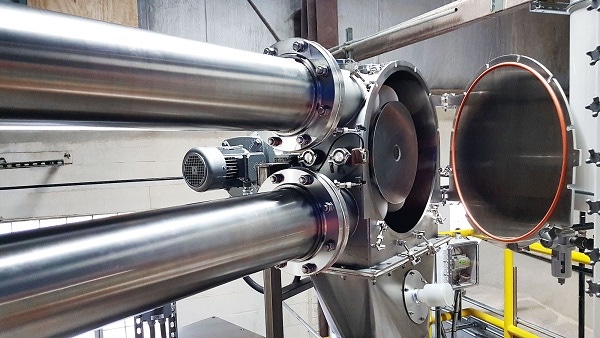

In response to industry demands for an enclosed, hazard-free, durable solution for conveying all types of chemical products, Luxme International’s tubular chain conveyor is designed to meet the unique requirements of the chemical processing industry.

The design of a high-quality, chemical-grade conveyor will vary depending on the properties of the material being transported. While some materials are highly combustible and require special handling, such as anti-static and no metal-to-metal contact components, others demand the material to remain within the pipe due to its hazardous health impacts.

Regardless of the material, it is paramount to provide a high level of protection from sparks, material dusting, contamination, high and low levels of humidity, flow surges, temperature changes, and other factors that can potentially alter the quality of the product or render operations to be unsafe. Statistics show that there were 1.9 injuries and illnesses per 100 workers in the chemical manufacturing industry in 2018. A total of 18 fatalities were recorded in the same year, and while this is down from 28 in 2015, safety remains a top priority for processors.1

By enclosing materials, the tubular chain conveyor contains dusty and hazardous materials, safeguarding workers at the same time as protecting the conveyed material from external influences. It is also resistant against internal pressure buildup and helps to contain propagating flame, making it suitable for handling potentially explosive chemicals.

The conveyors are built with quality materials including chemical-grade stainless steel and FDA-approved components. By using a low-horsepower motor, energy consumption is less than the traditional pneumatic conveyors.

The SaniLux USDA-accepted CIP (clean-in-place) conveyor ensures the system is free from residues between batches without adversely affecting the product quality or line efficiency. The chain assembly for the CIP washdown application is approved by the FDA.

The conveyor itself comprises a fixed drive and tension assembly, which automatically tensions the chain continuously during the process and regulates it according to friction, product flow and variation in atmospheric/product temperature.

Luxme, Brossard, QC, Canada 450-619-1999 www.luxme.com

Here are more articles that may interest you:

Addressing Drag Conveyor Chain Inefficiencies, Lifespan

What is Mechanical Conveying?

Choosing the Right Conveyor

3 Essential Factors to Consider for Your Next Food Grade Conveyor

How to Choose a Tubular Chain Conveyor

You May Also Like