Best Practice Food Conveying Solutions

An expert shares insight on selecting the best type of conveyor and optimizing it for specific types of powdered food products.

January 17, 2024

In the food processing industry, buyers and sellers who handle and package dry particulates like powdered sugar, flour, coffee, cocoa, food additives, protein concentrates, and isolates can be challenged when trying to select the best type of conveyor to overcome common issues.

There can be substantial difficulties in conveying these types of ingredients if the powder is sticky, hygroscopic, or tends to cake or pack. Powdered food products and ingredients can also present significant health and safety hazards when they become airborne and are combustible or have explosive properties.

To offer guidance in resolving these issues, Don Mackrill, regional sales manager at Automated Handling Solutions (AHS), shares insight on not only selecting the best type of conveyor for the application, but also optimizing it for specific types of powdered food products.

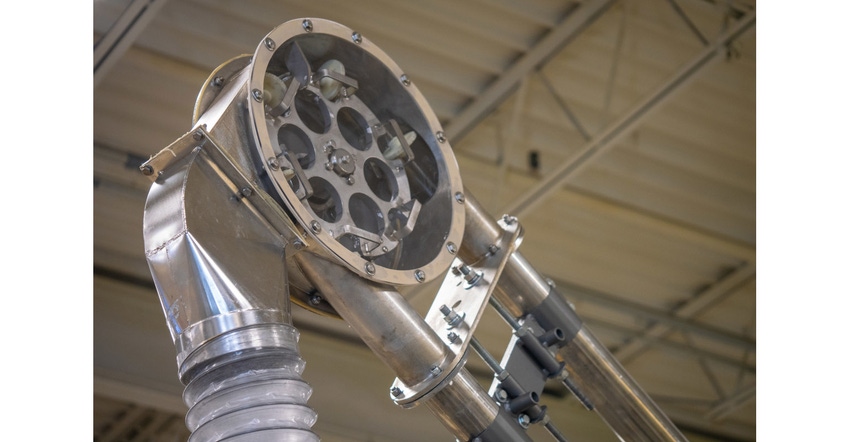

Issues such as product flowability, abrasiveness, and cohesiveness should always be considered when contemplating the best conveyor options (image courtesy of Automated Handling Solutions)

AHS offers a comprehensive suite of material handling equipment and industrial automation solutions, including Spiroflow, a global manufacturer of material handling equipment and provider of control systems integration, and Cablevey Conveyors, a manufacturer of patented tubular drag conveying systems for food and beverage and high value industrial applications.

Q: For the dry processing and bulk solids industry, what is the big picture that we should begin with?

A: While there are many conveyor options in the market, some are more effective at addressing issues like dust escape and explosion risk as well as caking, packing, and cleaning out residue between batches. Processors that minimize or eliminate these issues in the conveyor design will improve their safety, productivity, and product quality.

Q: What are some critical considerations for conveyor selection?

A: Selecting the ideal mechanical conveyor can be a daunting task for purchasers who may not be aware of the features and benefits of the different types available.

The most critical aspect to consider is the type of product you are trying to convey. Issues such as product flowability, abrasiveness, and cohesiveness should always be considered, whereas product degradation or the need to maintain a blend may be key aspects to consider in some applications.

The distances and rate of speed required to move the material is also a consideration. Does the conveyor need to pick up from or feed multiple locations, or follow a complex route around other equipment or structures? Are there any special safety considerations based on Area Classification, traffic, or other processes?

For food-grade applications, hygiene specifications and the ability to clean-in-place are key considerations.

There are several categories of enclosed conveyors that meet these requirements, including aero mechanical, flexible screw, and tubular cable drag designs. However, factors such as the type of and size of the powder and the specific challenges those materials create when conveyed often dictate the ultimate choice.

Flexible screw conveyors utilize rotating spiral or open helix screws within tubes to push product along and are mechanically dust tight and totally sealed during operation (image courtesy of Automated Handling Solutions.

Q: What do we need to consider to prevent caking and packing?

A: With powders, care must be taken to avoid the powder caking and clogging the conveyor, which can result in downtime and increased safety hazards during maintenance and cleaning.

An extremely efficient clean and reliable alternative is an aero mechanical conveyor, which uses evenly spaced discs to generate a high velocity air stream to fluidize and convey powdered products. Aero mechanical conveyors are totally sealed, tubular systems that ensure the dust-free transfer of even very fine powders without need of additional dust collection systems.

Unlike dilute phase pneumatic conveying systems, aero mechanical systems transport materials at lower speeds, so suspended particles experience significantly less shear forces. This minimizes breakage and caking and packing inside the tube. Because aero mechanical conveyors have near-to-total product transfer capability, any residual product in the system between batches is also minimized. However, if caking or build-up occurs, aero mechanical conveyors can be easily disassembled for regular, quick cleaning.

Q: In regard to containing fugitive dust, what is important?

A: For food processors, a priority is containing powdered products within the system, so they do not become airborne. When powder and bulk solids escape the conveyor, the “fugitive dust” can pose health, safety, sanitary, and even explosive risk, depending on the material and environment. According to OSHA’s definition of combustible dust explosions, any combustible material can burn rapidly when in a finely divided form. If such a dust is suspended in the air in the right concentration, under certain conditions, it can become explosive.

When moving powdered material in a plant, an enclosed system can address concerns over dust containment to deter explosions and prevent environmental contamination. An enclosed conveyor can prevent spillage, the release of airborne dust, the need for additional cleanup of the surrounding area, as well as the potential for powder contamination from the external environment.

Q: What types of powdered food can combust? How would you address this risk?

A: Sugar, grains, flour, and other powdered food products can combust, so it is critical that the conveyor system minimizes or eliminates potential sources of ignition, such as sparks or fire. Improper maintenance of conventional open mechanical conveying systems can become an ignition source since they utilize numerous moving parts. Bearings and out-of-alignment belt conveyors, for example, can be problem areas if they cause sparks or generate heat from friction.

Q: What types of enclosed conveyors are good choices to consider?

A: Flexible screw conveyors utilize rotating spiral or open helix screws within tubes to push product along and are mechanically dust tight and totally sealed during operation. Since air is not used as a conveying medium, there is no risk of dust contamination.

Tubular cable drag conveyors are also enclosed and use cables with discs attached at set intervals within a tube to gently pull powder from inlets to discharges.

Q: How would you compare enclosed conveyor options for potential combustion risk?

A: Although enclosed, pneumatic systems can still create a “dust cloud” inside the tube, as well as on exit. Because tubular cable conveyors do not suspend material in high-velocity airstreams, less “energy” is imparted into the conveyance and the slower velocity reduces any friction and heat generated to well below an ignition point, limiting it about 10 to 20°F above ambient temperature.

Q: How else can you mitigate dust accumulation risk in conveyors?

A: Dust accumulation risk can also be mitigated through sufficient cleaning to remove any potential powdered debris. For this, some tubular cable conveyor systems offer cleaning accessories such as brush boxes, urethane wipers, air knives, in-line sponges, in-line bristle brushes, as well as complete, multi-step, fully automated CIP wet cleaning systems.

Q: What can you tell us about specific powdered food challenges?

A: Although enclosed conveyors can be effectively used to convey powders in the food industry, the choice may be dictated by the specific product and size of powder.

Q: What risks does sugar pose and what conveyor type(s) can address these difficulties?

A: Since powdered sugar is highly flammable and explosive, conveying system design should minimize this risk. In fact, due to recent industrial accidents, government regulatory bodies like OSHA (Occupational Safety and Health Administration) and NFPA (National Fire Protection Association) have issued heightened regulations governing the handling of sugar. Furthermore, powdered sugar tends to pack and cake while conveyed. Like powdered sugar, granulated sugar is highly combustible, potentially explosive and will ignite at high temperatures.

Enclosed aero mechanical conveyors are an ideal choice for conveying large volumes of both powdered and granulated sugar to the mixer. Any dust created during conveying is contained within the conveyor, reducing the risk of explosions caused by static buildup and sugar dust clouds. In addition to being airtight, aero mechanical conveyors run quietly with minimal energy.

Q: What types of conveyors are suitable for flour?

A: Flexible screw conveyors are an ideal choice for flour. The flexible screw conveyor’s only moving part, the spiral, continuously mixes as it conveys. The conveyor can be configured with a drop out trap, quick release flanges, and a reverse bung that facilitates hygienic flour conveying when switching between different batches of flour.

When conveying flour where degradation is a concern, an aero mechanical conveyor is also a good choice. An aero mechanical conveyor creates an airstream which moves flour up the tubes along with high-speed discs and a stainless-steel cable. The material is transported gently through the airstream between discs, ensuring minimal handling and no dust generation due to the non-friable nature of flour. Any dust generated will remain suspended in the airflow together with the material and will not accumulate or come into contact with any potential ignition sources.

Q: What’s important when conveying ground coffee or mixes, and what’s a good option to consider?

A: When conveying ground coffee or mixes, dust control is of utmost importance due to combustible properties and the need for operator safety. Since ground coffee is hygroscopic, it easily absorbs moisture and is prone to clumping. Maintaining the consistency and size of the ground coffee is also essential for brewing a good final product. In addition, conveying systems processing different types of flavored coffees or mixes often must be quickly and thoroughly cleaned between product changeovers to prevent flavor cross-contamination.

With these considerations in mind, tubular cable drag conveyors are quickly becoming the conveyor of choice for coffee processors due to safe, gentle movement that minimizes dust hazard and product degradation while still offering high throughput. These conveyors provide very versatile layouts and can be used to pick up coffee grounds from different sources for transport over long, complex routes to various destinations.

Q: Any last thoughts for us to consider?

A: Given the variety of conveyor choices and powdered food ingredients that must be safely moved during processing, the potential risks warrant a careful examination of the available equipment options in consultation with experts.

A good option is to consult with a conveyor OEM or third-party expert that maintains comprehensive material test databases. Some even offer a test laboratory equipped with a complete range of conveyors to enable adequate testing of the specific application prior to making an investment in new equipment.

For more information, contact Spiroflow Systems at 704-215-2624 or [email protected], or visit www.spiroflow.com.

You May Also Like