Powder Handling Systems Deliver for Gum Supplier

August 28, 2014

For more than three generations and 75 years, Colony Gums, Monroe, NC, has been servicing the food, pharmaceutical, and chemical industries with the finest quality gums and stabilizers, making the company one of the forefathers in hydrocolloid ingredient supply. Family-owned and operated, Colony Gums takes pride in helping its customers develop special formulations, gum systems, and stabilizers to meet their specific product development and functionality needs.

The company handles a variety of gums such as Agar, Arabic, Carrageenans, Cassia, CMC, Guar Gum, Gum Ghatti, Karaya, Konjac, Locust bean Gum, Tragacanth, Xanthan gum, and stabilizer systems. Colony was using two bag dump hoppers and flexible screw conveyors from another supplier to handle the various gum materials. Limited conveying rates and operator safety concerns lead them to consider a new conveying system.

Requirements

Vice president Chris Muhlsteff called Spiroflow Systems with the following needs:

• Move powdered gum material out of bulk bags and 50-lb bags into two elevated powder blenders

• Improve conveying rates from a previous maximum of 9000 lb/hr to 30,000 lb/hr

• Improve productivity

• Maintain the quality of the material and minimize possible contamination

• Maximize operator safety by reducing the potential for injury

• Increase plant cleanliness with improved dust containment

• Maximize cost effectiveness of the new conveying system by reprogramming an existing control panel

Recommendations

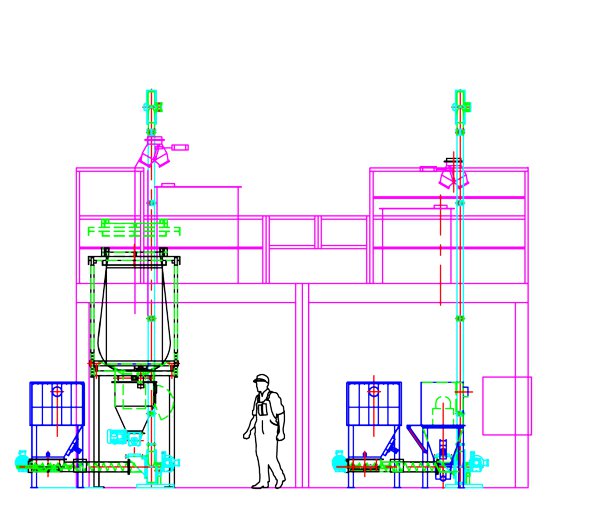

Spiroflow Systems recommended, installed, and commissioned two side-by-side powder handling systems to meet Colony’s requirements. The systems and the associated process steps for each are as follows:

System A:

• A stainless steel loss-in-weight bulk bag discharger with vibration and bottom massagers

• A stainless steel 3-in aero mechanical conveyor

• A stainless steel flexible screw conveyor

• A stainless steel bag dump station with a dust hood and vibration

• Reprogram the existing control panel to operate the bulk bag discharger, flexible screw conveyor and aero mechanical conveyor

System A Process Steps:

• A 2200-lb bulk bag containing the desired gum material is loaded into the loss-in-weight bulk bag discharger via forklift.

• The gum material is transferred from the base of the bulk bag discharger up 20 ft via an aero mechanical conveyor. The aeromechanical conveyor is 22 ft long and positioned at a 60º angle.

• The gum material exits the aero mechanical conveyor outlet into a large blender.

• 50-lb bags of gum material are manually added at the adjacent bag dump station fitted with vibration and a dust hood.

• A 5-ft-long horizontal flexible screw conveyor installed at the base of the bag dump station transfers the contents of the smaller bags into the aero mechanical conveyor.

• When appropriately blended the gum material in the large elevated blender is vacuum transferred to a screening system and then packaged.

• This conveying system is operated via an existing control panel that Spiroflow Systems reprogrammed.

System B:

• Two stainless steel 3.5 cu ft hoppers with vibration

• Two stainless steel flexible screw conveyors

• One stainless steel 3-in. aero mechanical conveyor

• One weigh batch control panel

System B Process Steps:

• 50-lb bags of gum material can be simultaneously emptied into two bag dump stations fitted with vibration.

• A 5-ft-long horizontal flexible screw conveyor installed at the base of one hopper transfers the contents of the 50-lb bags into the aero mechanical conveyor.

• A second 4-ft-long flexible screw conveyor, positioned at 30º and installed at the base of the second hopper, also transfers the contents of the smaller 50-lb bags into the aero mechanical conveyor.

• The 22-ft-long aero mechanical conveyor positioned at 60º transfers material up 20 ft to another elevated blender or directly to screening and packaging.

• This system is operated via a custom weigh batch control panel.

Results and Benefits

The new powder handling systems delivered on all of Colony’s requirements.

Cleaner: The new systems are cleaner because they completely transfer contents from the bag dump station and hoppers without residual. This was an issue with the previous equipment. The new system also incorporates increased dust control so less material escapes into the atmosphere.

Safer: The new systems are safer because safety switches are incorporated at potentially dangerous locations to prevent injury. For example, if a hopper grate is not in place the flexible screw conveyor at the base of the hopper will not operate.

Faster: The new systems provide Colony Gums with a conveying rate of 20,000/hour enabling the company to increase production by a factor of 50%.

Productivity: The new conveying system allows for simultaneous loading of material from the bulk bag discharger, as well as the bag dump station and two hoppers. Furthermore, the addition of the bag dump station increases manual loading by up to 50%. Now three operators, instead of two, can empty 50-lb bags at the same time.

Cost-Effective: The company saved money by having Spiroflow Systems reprogram an existing control panel.

Reduced Waste: Waste was reduced as the new systems completely transfer contents from the bag dump station and hoppers without residual.

Muhlsteff is pleased with the results. “Our Spiroflow powder handling systems have been operating since 2007,” he said. “The solution is reliable and continues to exceed our expectations. We enjoy working with the Spiroflow team. They understand our needs and are always ready to help with any changes in our production needs. They are a supplier we can count on.”

For more information on Spiroflow Systems Inc., call 877-294-9595 or visit www.spiroflowsystems.com.

For related articles, news, and equipment reviews, visit our Material Handling & Transportation Equipment Zone

You May Also Like